#Industry News

Metal Stamping Defects

8 types of common metal stamping defects

1. Crack

Cracks that occur when metal is subjected to tensile stress.This type of crack usually occurs in localized areas of the metal, particularly where high strains or stress concentrations are present.Cracks are a deformation and damage phenomenon in metal that may lead to part damage and quality issues.

2. Wrinkling

In the metal stamping process, wrinkles refer to the irregular deformation of ripples and wrinkles that appear on the surface of metal parts.Typically occurs in thin sheets or curved areas, especially when stress is applied to a punch or press.

3. Fold

A hem is a burr or flake that forms on the edge of a metal part.A hem often forms when a cutting tool cannot cut completely through the metal, leaving some metal at the edge of the part.

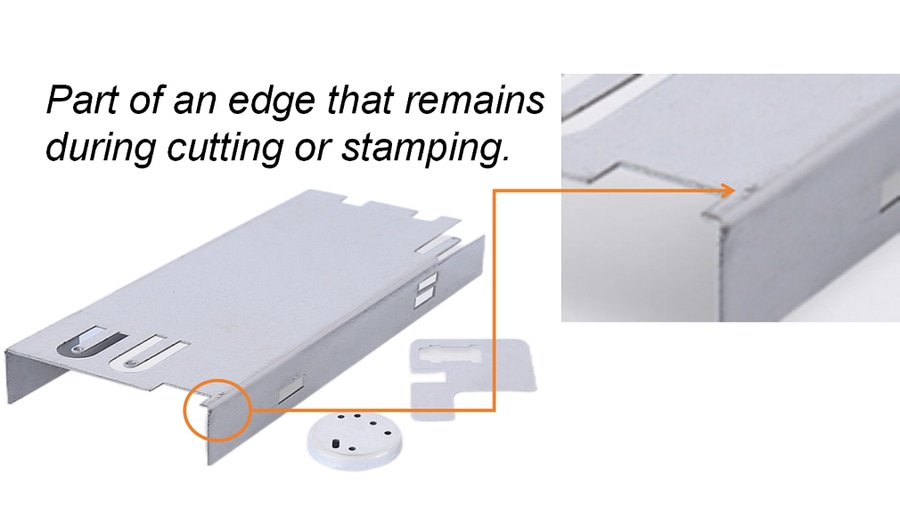

4. Blanking Burrs And Missed Cuts

Blanking burrs refer to instances in the cutting or stamping process where the edges of metal components are not fully severed, leaving behind uncut portions.This may manifest as small holes or uncut connecting points, potentially impacting the functionality and structure of the component.If missed cuts are not promptly identified, they may lead to damage during subsequent processing or usage.

5. Uneven Stretching

Uneven stretching refers to the uneven distribution of tensile strain experienced by metal components during the stamping process. This results in certain areas of the component undergoing greater stretching, while other regions experience comparatively less stretching.

6. Indentation

In the metal stamping process, indentations are depressions, marks, or marks produced on the surface of a metal part, usually caused by contact or pressure between the die and punch.Indentation will cause the surface of the part to be uneven, affecting the appearance and texture, and reducing the overall aesthetics. Severe indentation can affect the mechanical properties of the part, such as strength and durability.

7. Surface Defects

Surface strain refers to scratches, abrasions or other irregularly shaped damage on the surface of metal parts.Such surface defects can cause the part to have a poor appearance, affecting quality and performance.

8. Burst

Bursting is a crack or break that forms on the edge or surface of a metal part.It usually occurs in holes, edges, or other areas of stress concentration on parts.Such defects can cause a reduction in the strength of the part, affecting its performance and lifespan.

Above we have learned about 8 common metal stamping defects. What causes these metal stamping defects? Are there any prevention methods? If you want to know more, please click on the link below to view a more detailed article.