#Industry News

Causes of defects in metal forming process

6 types causes of metal forming defects

There are six primary factors contributing to the occurrence of metal stamping defects:

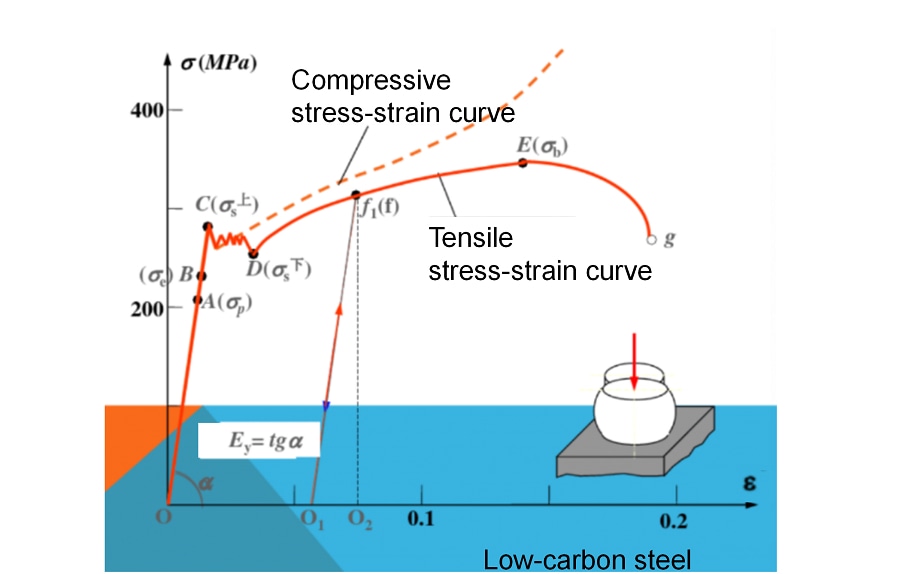

1.Excessive Strain:

When metal undergoes excessive strain during stamping, particularly at edges or bends, it is prone to developing tensile cracks. Overly aggressive shape alterations may surpass the metal's ductility, leading to such issues. Uneven distribution of strain during stamping can result in localized excess material, causing wrinkles or unevenness.

2.Metal Material Quality:

Metals with high levels of impurities, pores, or defects are more susceptible to developing tensile cracks. Selecting inappropriate metal materials for stamping, or those lacking sufficient material properties, can readily lead to wrinkles. The choice of metal material can also influence its cutting ease, with metals possessing low ductility being more prone to issues like edge folding and blanking burrs.

3.Inadequate Cutting Tools:

The use of dull or worn cutting tools may yield unsatisfactory cutting outcomes, such as material leakage or failure to fully penetrate the metal, resulting in folded edges.

4.Mold Design Flaws:

Poor die design, particularly at edges, can subject the metal to excessive stress during stamping, leading to cracks. Improper mold geometry, angles, fillets, and other factors can cause uneven stress distribution during stamping. Additionally, the shape, size, and surface quality of the punch and die all play crucial roles in determining the final indentation.

5.Improper Stamping Parameter Settings:

Incorrect stamping parameters, such as excessive punch speed, inappropriate temperature, or overly high punch pressure, can induce tensile cracks. Improper punch speed or other parameter settings may also lead to subpar cutting results, resulting in material leakage and folding. Higher stamping speeds may amplify impact forces, resulting in deeper and more pronounced indentations, while slower speeds may produce shallower marks.

6.Inadequate Lubrication:

Insufficient lubrication can elevate friction during cutting, heightening the risk of tensile cracks. Furthermore, uneven stretching due to inadequate lubrication can impair cutting effectiveness, leading to edge folding, material leakage, and other issues.