#Industry News

What is progressive die stamping

Definition and advantages

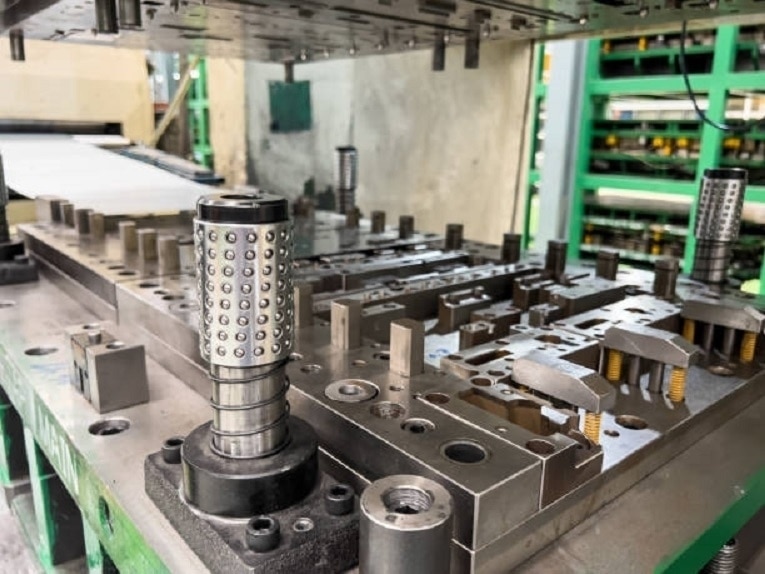

Progressive die stamping, also called continuous die stamping, is a cutting forming process. It is a set of sequential dies that step through multiple blanking and forming steps, ultimately transforming metal strip (or coil) into a well-formed part. It divides the workpiece into multiple equidistant stations in the mold, and sets one or several basic stamping processes on each station to complete the processing of a certain part of the stamped workpiece.

Progressive dies are special tools used for metal stamping processing. Perform multiple operations in the mold in a sequential and progressive manner without using separate tools and settings for each operation.

Progressive molds have many advantages, mainly reflected in:

(1) High production efficiency: Progressive molds can realize the continuity and automation of the production process, reduce downtime and production cycles, and improve production efficiency.

(2) Accuracy and repeatability: The progressive die can precisely control the stamping process to ensure consistent size and quality of each part with high repeatability.

(3) Suitable for complex shapes: The progressive die is suitable for stamping parts with complex shapes, and can gradually form complex contours and structures by executing multiple processes step by step.

(4) Material savings: Because progressive dies complete the molding process step by step, materials can often be used more efficiently and waste generated less.

(5) Strong adaptability: The progressive die has strong adaptability and can be used to produce parts of various sizes and shapes, from small parts to large plates.