#Industry News

Manufacturing Of Progressive Die

basic step

The manufacturing of progressive dies is a complex and precise process. Basic steps include design, material selection and preparation, processing, heat treatment, assembly and commissioning, and surface treatment.

1. Usually, high-strength tool steel is the first choice for mold manufacturing materials to ensure that the mold can maintain stability during long-term high-intensity production.

2. Making molds usually involves various machines and processes such as turning, milling and EDM.

●Turning uses a lathe to rough machine mold parts to obtain basic shapes and dimensions.

●Milling uses a milling machine to finely machine parts, producing special shapes and fitting dimensions.

●Electrical discharge machining uses electrodes and computer-controlled electrical discharge machines to process some parts with complex shapes.

●Wire EDM Workpieces are cut through a computer-controlled wire EDM machine used to create small internal and external shapes.

3. In order to improve the hardness and wear resistance of mold parts, heat treatment is an indispensable part. Quenching heats the part to a critical temperature and then cools it rapidly, giving it excellent physical properties. Tempering reduces the brittleness after quenching and ensures that the mold is not easily damaged during long-term use.

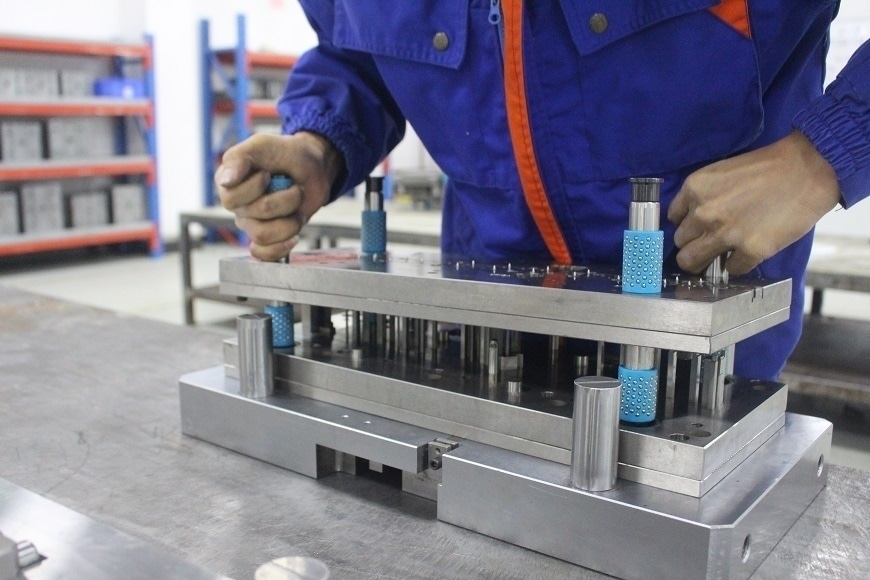

4. After all parts are processed, the assembly phase begins. The assembly of the mold requires a high degree of skill and precision. The commissioning process involves checking the sequence of individual processes and fine-tuning the mold to ensure it runs smoothly.

5. Of course, surface preparation is a step that cannot be ignored. In order to improve the wear resistance and surface finish of the mold, surface grinding, polishing and coating are common processes to ensure that the mold has good performance in production.