#Industry News

What Is Casting Defect

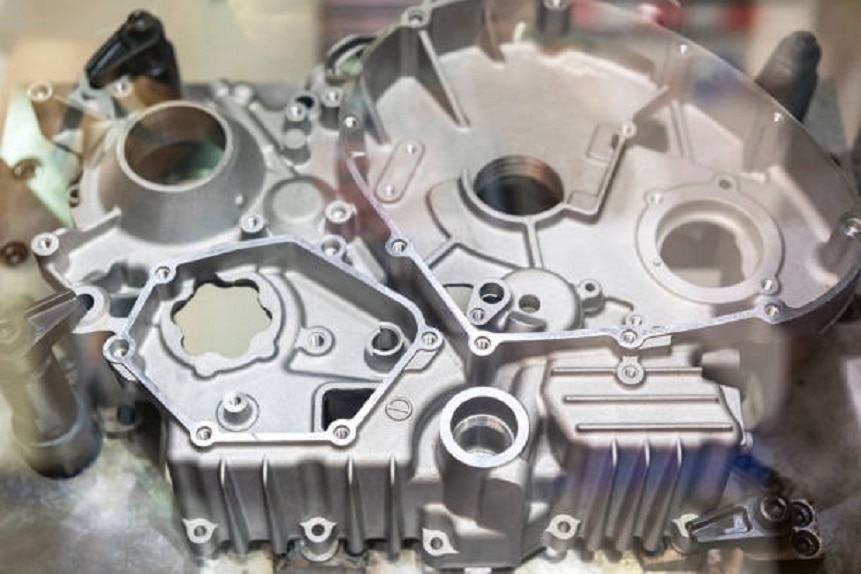

METAL CASTING DEFECT

Casting defects refer to imperfections, irregularities, or flaws that occur during the metal casting process, leading to substandard quality, compromised performance, or undesirable appearance of the final product. Casting defects are not only detrimental to the quality and safety of the final product but also pose significant challenges to the casting process. Beyond the immediate impact on quality, these defects can lead to additional complications and expenses throughout the production cycle.

For instance, gas porosity and shrinkage defects not only compromise the structural integrity of the casting but also hinder the material's ability to withstand stress and environmental factors. This may necessitate additional treatments or reinforcements to meet performance standards, adding to manufacturing costs and time.

Metallurgical issues, such as improper alloy composition or inadequate heat treatment, can result in material weakness or susceptibility to premature wear and failure. Correcting these defects often involves extensive testing, reworking, or even material scrapping, further delaying production schedules and increasing expenses.

Problems with pouring metal, including inadequate flow or turbulence, can lead to incomplete fills or uneven distribution of material within the mold cavity. This not only affects the dimensional accuracy of the casting but also introduces internal stresses and defects that may compromise its structural integrity.

Furthermore, mold material flaws, such as insufficient strength or improper venting, can result in surface defects or incomplete shapes. Addressing these issues may require redesigning molds, sourcing alternative materials, or implementing additional processing steps, contributing to production delays and costs.

Lastly, shape imperfections, such as distortion or warping, can result from uneven cooling or insufficient support during solidification. Rectifying these defects may involve secondary machining operations or corrective heat treatments, further complicating the production process and impacting overall efficiency.

In summary, casting defects not only affect the quality and safety of the final product but also introduce complexities and expenses across the entire production cycle, from material sourcing and processing to finishing and assembly. Mitigating these challenges requires a thorough understanding of the underlying causes and effective implementation of corrective measures throughout the casting process.