#Industry News

13 Types Of Pin Fasteners

Complete Summary 2024

Cotter pins are a simple and effective mechanical fastener made of a metal rod bent into a U-shape with a loop at one end and two legs at the other. They are inserted into a pre-drilled hole and the legs are bent to secure.

Dowel pins are cylindrical pins used for precise alignment and fastening of components, usually made of stainless steel, carbon steel or alloy steel. They are inserted into pre-drilled holes and held in place with tight tolerances.

Spring pins (locking pins) are spring-locking devices used to quickly connect and fasten mechanical parts, commonly used in agricultural, construction and transportation equipment.

Spring pins (elastic pins) are resilient cylindrical fasteners, usually made of high carbon steel, stainless steel or alloy steel, formed by rolling or stamping.

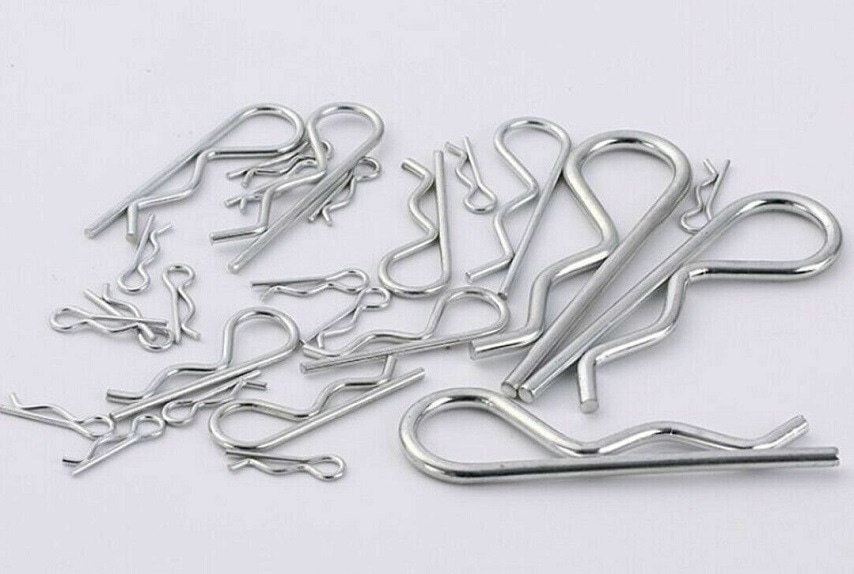

Wire lock pins are pins with spring-locking wire loops, used to quickly connect and fasten mechanical parts, usually made of stainless steel, carbon steel or aluminum.

Tapered pins are used for precise alignment and fastening of mechanical parts, inserted into pre-drilled tapered holes, and achieve a tight fit through their gradually increasing diameter.

L-handle pins have an L-shaped handle and are designed for easy operation. They are suitable for applications that require frequent adjustment and fixation, such as agricultural machinery, construction equipment, and transportation equipment.

U-shaped pins (fork pins) are used to connect and articulate two parts. They are usually used with U-shaped pins and split pins. They are widely used in agricultural machinery, construction equipment, transportation equipment, and industrial machinery.

Pawl pins have a spring ball or pawl, which provides a self-locking function to ensure that the pin will not loosen. They are commonly used in various tools and mechanical equipment.

Hook pins (trailer pins) are used to connect and fix equipment such as trailers and agricultural implements. They are usually equipped with a safety locking device. They are inserted into pre-drilled holes and fixed with a safety lock or split pin to ensure that the equipment will not fall off during towing.

Grooved pins are cylindrical pins with longitudinal grooves. They are designed to increase grip and shock resistance to ensure that they will not loosen during use. They are suitable for connections that require additional torsion protection.

Snap pins have a spring snap ring to provide a reliable lock. They are suitable for applications that require quick connection and fixation, such as outdoor equipment and sports equipment.

Bend pins are cylindrical pins with a bent portion, usually made of carbon steel, stainless steel or alloy steel. The bent portion provides an additional locking function to ensure the stability of the pin. They are widely used in situations where additional fixation and prevention of rotation are required, such as construction and furniture manufacturing.