#Trade Shows & Events

Automatically to more quality

IEF-Werner at the Automatica 2023.

Intelligent automation is one of the pioneering key technologies for every industrial sector. At Automatica 2023 IEF-Werner will present sophisticated solutions that enable companies to design handling processes economically and safely - from servo presses to palletising systems.

Furtwangen, 15.05.2023 - With energy-efficient systems, companies save costs and strengthen their competitiveness. To support its customers in this, IEF-Werner is showing the ecoSTACK at automatica. The compact and energy-efficient palletising system manages completely without expensive compressed air. The palletiser saves further energy by automatically switching off components that are not currently needed. The power supply is interrupted as often as possible - for example, when the machine is at a standstill, at the end of a shift or during breaks. This also has an effect on the service life of the entire system. The ecoSTACK is designed as an in-line system and enables the continuous loading and unloading of pallets of different sizes -especially in quarter or octagonal sizes.

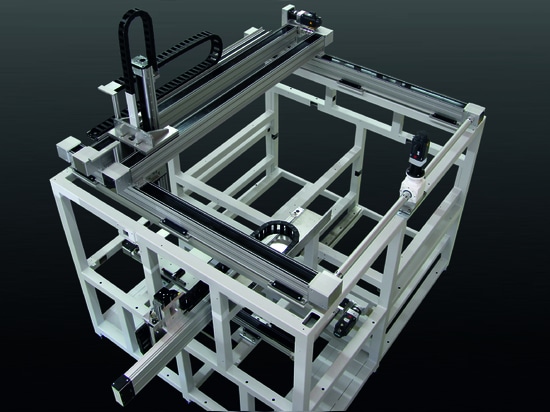

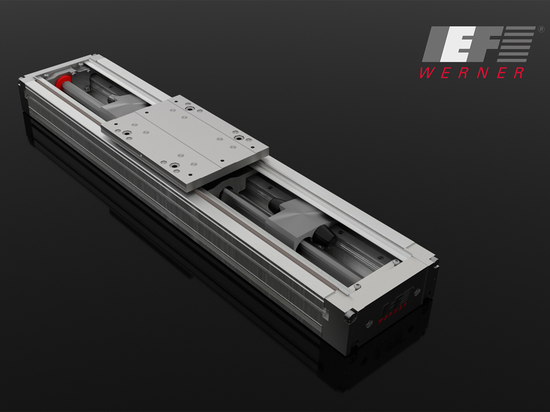

IEF-Werner will also be presenting a gantry system with the toothed belt axis module 115/25 in Munich. With this, the automation specialist will be demonstrating how pallets or boxes weighing up to 40 kilograms can be handled safely with the help of a large gantry system. For this purpose, the basic body of the module is above all resistant to bending and torsion. This is particularly advantageous for the construction of gantry systems: Designers are able to implement large spans. Even with high loads and large strokes, no additional support structures are required. Users can not only reduce their costs with this system - compared to alternative solutions, they also benefit from a significantly faster system set-up. Strokes of up to 6.5 metres can be realised. The linear unit is available in stroke increments of 60 millimetres each.

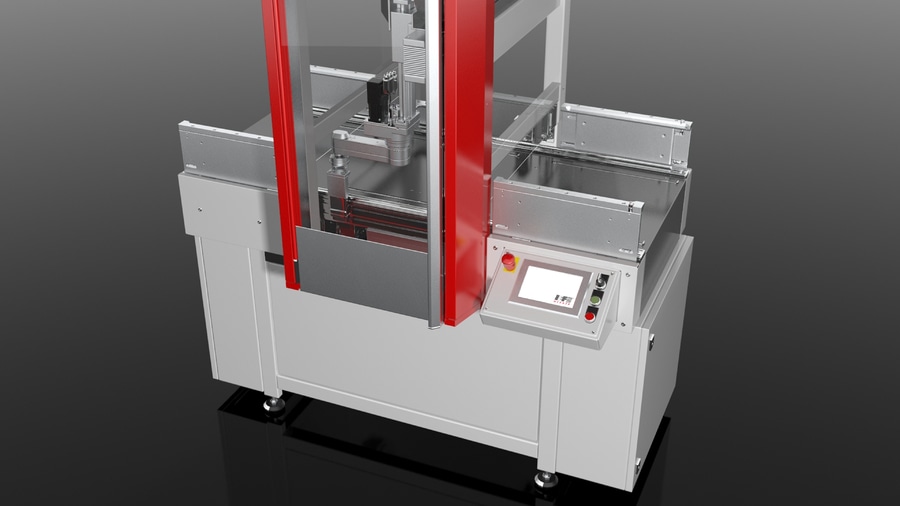

IEF-Werner will also bring its successful aiPRESS servo press series as an exhibit. The flexibly designed systems can be integrated into automated production lines as well as manual workstations. The presses have several standardised software and simple I/O interfaces. The servo press is available in four sizes - the smallest has a force of three kilonewtons with an opening of 180 millimetres, the largest can achieve up to 100 kilonewtons with an opening of 350 millimetres. Users can thus automatically join components with a high precision of a few micrometres. The aiPRESS can also check the accuracy and classify the joined assemblies into good and bad parts or even into different quality levels. The automation specialist has further optimised the series now, equipped it with special functions and subjected it to a type examination. IEF-Werner will also provide information about this at its trade fair stand.

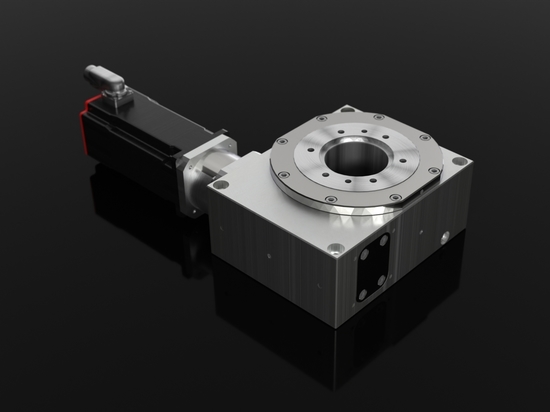

IEF-Werner will also be showing its extensive range of handling technology. This includes precise manual adjusters for linear and rotary positioning tasks of all kinds or linear units that can be adapted to individual applications.

IEF-Werner at automatica, Hall A5, Stand 203