#Industry News

Fresh ideas from young minds

Spindle support for linear unit profiLINE 140

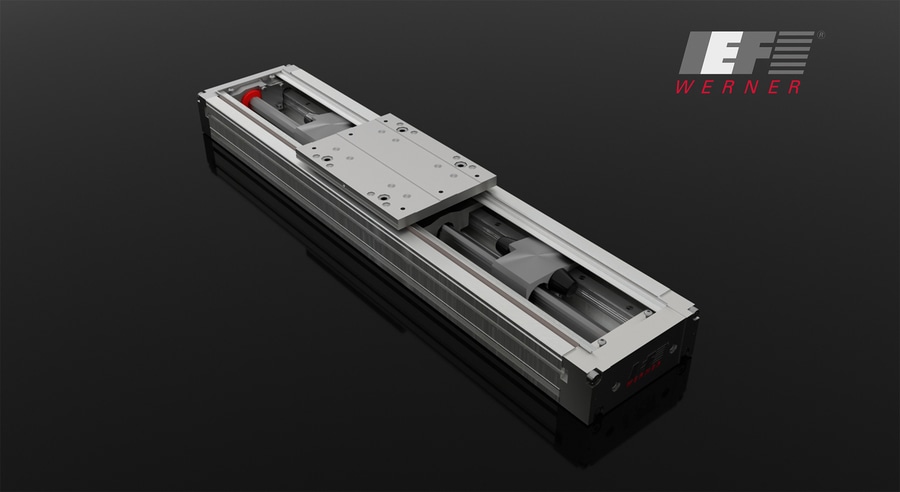

IEF-Werner has further developed the profiLINE 140 precision linear unit with spindle drive and equipped it with a support that reliably prevents the spindle from swinging open with large strokes and enables significantly higher travelling speeds. This innovation was developed as part of a bachelor's thesis.

IEF-Werner has developed the positioning units with spindle drive of the profiLINE series to combine the positive properties of a linear axis and a precision slide. With these linear units, the spindle nut converts the rotary movement into a linear movement. Linear axes with spindle drive enable high feed forces and can therefore also move heavy loads over travel distances of up to 1.5 metres at low to medium speeds. They also offer high posi-tioning and repeat accuracy. Compared to axes with toothed belt or direct drives, spindle axes have an advantage up to a certain length. Combined with a large number of standardised as-sembly elements and in conjunction with other linear units from IEF-Werner, complex, multi-axis positioning systems can also be set up. Thomas Hettich, head of the linear axes product area at IEF-Werner: "The spindle drives are used in handling technology, factory automation, plant construction, palletisers and mechanical engineering in general

Avoid oscillation

With all spindle-driven linear units, undesirable oscillation of the spindle occurs above a certain stroke - at high speeds. This shortens the service life of the unit. "This means that our custom-ers can only operate the axes at a limited speed or with a limited stroke," Hettich explains. With a spindle support, on the other hand, the advantages of a spindle axis can also be utilised for longer strokes. "By eliminating disruptive vibrations, the spindle speed can be increased and the customer ulti-mately benefits from shorter cycle times," Roland Wertz, Head of Research & Development at IEF-Werner, adds. The design was to be realised as part of a bachelor's thesis.

Investigate and evaluate

For Anton Dold, who was in the final stages of his mechatronics studies the DHBW Karlsruhe, this was an exciting task. The task was to investigate and evaluate possible bearing technologies and the kinematics of the support. Anton Dold: "In the concept phase, we considered and evaluated various options for the technical realisation of the spindle support. The criteria included: Cost, ease of maintenance and integrability into the existing linear axes." Once the concept phase was complete, the student set about selecting and dimensioning the components used together with the experts from IEF. Finally, the solution had to be structurally integrated into the existing profiLINE 140 positioning unit. Both versions - with and without support - are absolutely compatible: the slide length, drilling pattern, height and width are identical. Only the overall length is slightly longer for a profiLINE 140 with spindle support.

Convincing advantages

The user benefits from our new development right down the line," Product Manager Hettich promises. "It starts with the ease of maintenance of the spindle support." Operators do not have to dismantle any components to lubricate them. The plain bearing that supports the spindle can be replaced if necessary - without having to remove the superstructure, spindle bearing or linear unit. There is therefore no loss of position during replacement and no special tools are required.

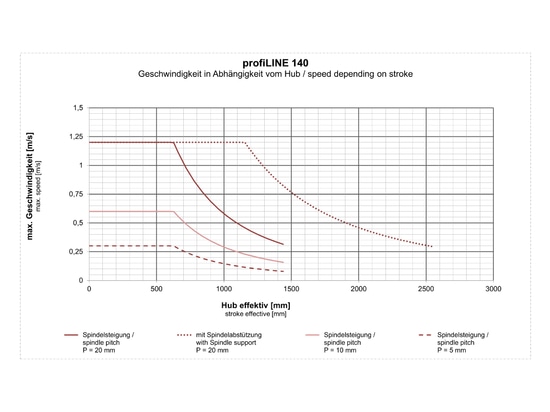

However, the most important aspect of this development is that the possible stroke of the profiLINE 140 linear unit has been increased to up to 2,500 millimetres. In addition, the stroke range in which it can be positioned at maximum travelling speed has been increased. "With the spindle support the linear unit achieves around twice the stroke at the same speed compared to a unit without spindle support - or three times the speed at the same stroke," Wertz summarises.

Attractive for students

Anton Dold successfully completed his studies with this bachelor's thesis and now works as a design engineer at IEF-Werner. The work was divided into several phases - from the basics to the development and construction of the spindle support. "To give me a good basis, IEF-Werner provided the information about the existing linear axes and a lot of empirical values," Dold recalls. As an employee of the R&D department, he was in constant dialogue with the various experts. This meant that open questions and current findings could be discussed immediately and development could be driven forward in a targeted manner..

This bachelor's thesis was a win-win situation for both sides. Hettich explains: "Anton Dold was able to solve an exciting and challenging task that prepared him for his professional life as a design engineer, and we benefit from an innovative solution that we will now transfer to other sizes in our profiLINE range.”

IEF-Werner always offers interesting topics for final theses. The special thing about this is that the students' results do not disappear in a drawer once the work has been completed. The automation specialist actively utilises them to increase customer benefits. The experts attach great importance to providing comprehensive support to the junior staff during their time at IEF-Werner.