#Industry News

Explosion hazard averted

IEF-Werner offers linear axes for ATEX zones 2 and 22

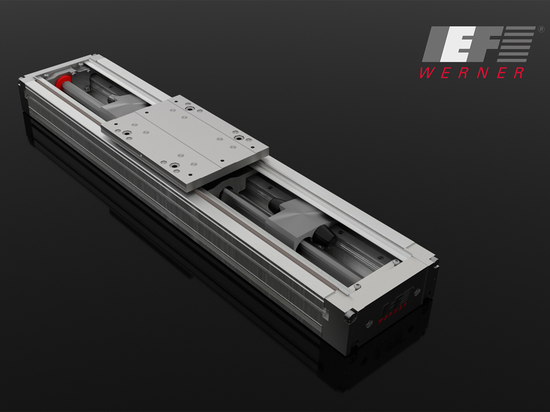

If companies work with flammable materials, safety plays a special role for them. Only suitable products and components can be used in potentially explosive systems. IEF-Werner has therefore designed its linear guides for equipment category 3, ATEX zones 2 and 22. The designer always knows for which environment and temperature a component is suitable and whether he is complying with the legally compliant explosion protection.

Furtwangen, 23.06.2023

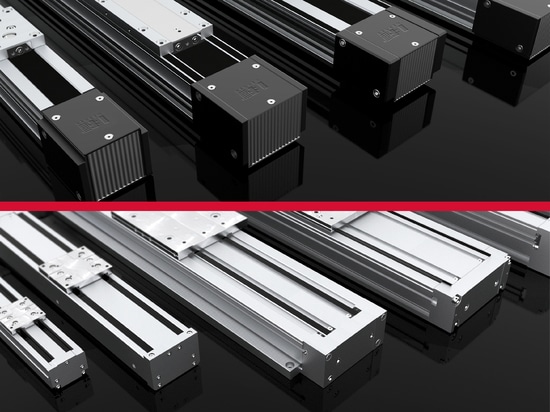

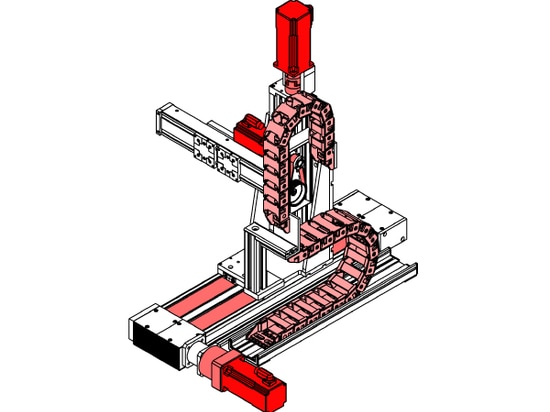

What does a designer have to consider in order to install components such as linear guides in systems that are used in potentially explosive atmospheres? "Customers have been approaching us with this question more and more frequently," Thomas Hettich, Product Manager at IEF-Werner GmbH, says. "We have been supplying our toothed belt and spindle drives for explosion protection areas on request for a very long time. In this version, they are suitable, among other things, for use in feeders of powder coating and wet painting plants, in the filling of chemicals or also in battery cell assembly - in other words, everywhere where an explosive atmosphere can occur for a short time during operation. Triggers are, for example, flammable gases, vapours and mists (Ex zone 2) as well as explosive dusts (Ex zone 22). Possible ignition sources include surfaces that have become hot due to the warm-up of longitudinal guides or belt pulleys. Other hazards: mechanically generated sparks, stray electrical currents and static electricity. "That's why various adaptations are necessary for these danger zones in toothed belt and spindle drives," Hettich describes.

IEF-Werner has appropriately modified linear units in its portfolio for these requirements. Additional earthing points are attached to the linear units. Separate earthing bars are used to combine the earthing cables. Supplementary components such as terminal boxes are also designed for the potentially explosive area.

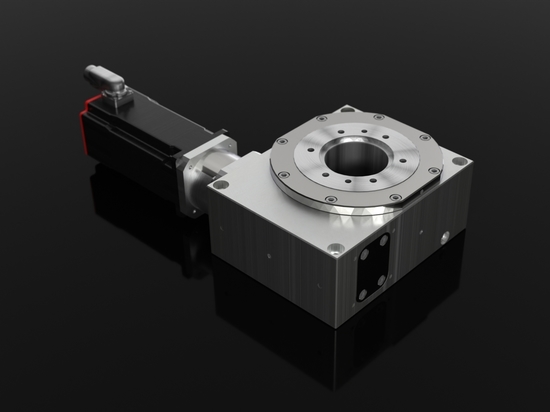

"In the case of timing belts or energy chains, one of the things we look for is an electrically conductive surface. If this were to become statically charged, there is a risk of sparking," Hettich explains. "For this reason, we rely on couplings made of electrically conductive elastomers for the spindle drives." Only planetary gearheads and motors with a sufficient level of protection are installed.

Every customer receives documentation with an ignition hazard assessment for his classified component. This enables him to safely install the IEF component in his production process. By adapting the internal processes, including a checklist for internal production control, we can now handle enquiries and projects in the ATEX area more rationally and safely than before," Thomas Hettich sums up.