#Trade Shows & Events

Handling made easy

IEF-Werner at Motek 2023

At Motek (10 to 13 October, Stuttgart), IEF-Werner will be showing intelligent solutions for production and assembly automation as well as handling technology. Among other things, the automation specialist will be presenting its successful aiPRESS servo press series at the trade fair.

Furtwangen, 15.08.2023

The flexibly designed aiPRESS servo press series can be integrated into both automated production lines and manual workstations. The presses have several standardised software and simple I/O interfaces. The series is available in four sizes - the smallest has a force of three kilonewtons with an opening of 180 millimetres, the largest can handle up to 100 kilonewtons with an opening of 350 millimetres. Users can automatically join components with a high precision of a few micrometres. The aiPRESS can also check the accuracy and divide the assemblies into good and bad parts and even into different quality levels. The automation specialist has now further optimised the series, equipped it with special functions and subjected it to a type examination.

Reducing costs and strengthening competitiveness - companies can achieve this, for example, with the compact and energy-efficient ecoSTACK palletising system. This system does not require any expensive compressed air. The palletiser saves further energy by automatically switching off components that are not currently needed. The power supply is interrupted as often as possible - for example when the machine is at a standstill, at the end of a shift or during breaks. This influences the service life of the entire system. The ecoSTACK is designed as an in-line system and enables the continuous loading and unloading of pallets of different sizes - especially in quarter or octagonal sizes.

IEF-Werner will also present its linear units with metal belt cover. This cover protects the linear drive from the ingress of dirt and particles on the one hand and prevents the release of particles into the environment on the other. This makes the drives suitable for clean rooms according to ISO 14644-1 from class 1 to 8, which has been tested and certified by the Fraunhofer Institute for Production Technology and Automation. Manufacturers from the pharmaceutical and medical technology sectors can thus meet the cleanliness requirements for linear units.

IEF-Werner is also presenting a gantry system with the toothed belt axis module 115/25, which allows pallets or boxes weighing up to 40 kilograms to be handled safely with the help of a large gantry system. This is ensured by the bending- and torsion-resistant basic body of the module. With gantry systems, designers are able to implement large spans. Even with high loads and large strokes, no additional support structures are required. Users save costs with this system compared to alternative solutions and benefit from a significantly faster assembly.

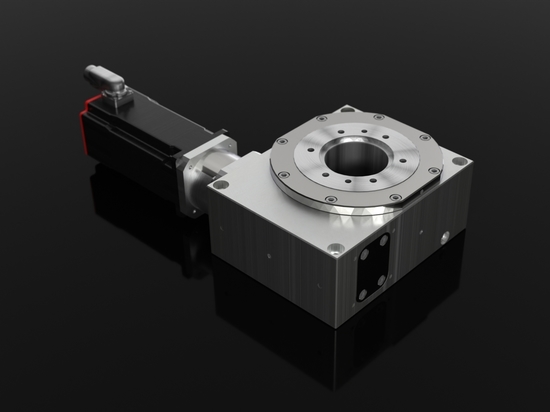

Another topic is the domiLINE adjustment unit. With this proven adjustment slide, for exam-ple, measuring systems such as image processing can be moved manually to any possible po-sition with extreme precision. At the trade fair, IEF-Werner will be demonstrating this vividly with a pocket watch from the German Watch Museum in Furtwangen, the headquarters of IEF-Werner. The modular adjustment unit has slide widths of 30, 50, 80 and 120 millimetres. This makes the user very flexible. For the smallest version, for example, four different strokes of five to 20 millimetres each are available from stock, the largest from 25 to 100 millimetres. Operators can not only connect slides to each other, but also to manual turning units.

IEF-Werner will also be showing its extensive range of components for handling technology that can be adapted to individual applications.

IEF-Werner at the Motek, Hall 5, Booth 5220