#Product Trends

DPH series Blister Machine-the embossing station

DPH series Blister Machine-the embossing station

In the embossing station, a code (e.g. batch no. expiry date) consisting of letters and/or numbers is embossed into the formed and sealed web by dies. Nowadays because of the track & trace requirement in pharmaceutical industry, this embossing station can be designed to equipped inkjet printer to spurts numbers, graphics or QR codes on the web side or the lidding side of the blister.

In the perforation station, the formed and sealed web can also be perforated between the individual pockets to allow them to be separated from the pack at the time of use. Conventionally, perforation and embossing remain in one station, but this will influence the clarity of each, for the high speed Blister Machine the influence will be more, so we recommend to add a perforation station, to separate the perforation from the embossing station, but this is optional not compulsory.

Replacement of the embossing mold

Run the Blister Machine to separate the upper and lower mold, let the lower mold at its lowest position; Then for safety we must power off the Blister Machine when replace the molds; Loosen the locking screw of the embossing upper plate (13), loosen the pressure plate, take out the embossing upper mold (14) and embossing upper plate (13) by handle1 (11). Then loosen the locking handle (10) to loosen the embossing lower mold (15), after that pull the handle2 (12) and take out the embossing lower mold (15).

After take out the old molds, then install the new molds

Let the new embossing upper mold (14) fixed on the embossing upper plate(13); Then push it to the correct position from outside to inside by handle1(11); Fix it on the embossing cover plate by locking screw; Push the embossing lower mold (15) to the suitable position by handle2 (12), and fix it on the embossing guide plate (7) through the clamp handle (10).

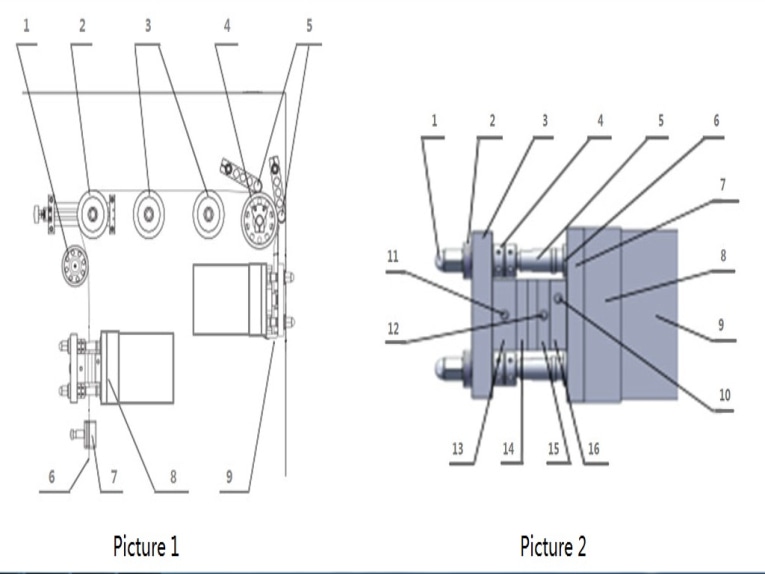

The schematic diagram of the embossing and Punching station

Picture 1

1. Overall Guide Roller 2. Adjusting Press Roller 3. Carrier Roller 4. Punching Index 5. Press Roller 6. The Formed & Sealed Web 7. Embossing Guide Rail 8. Embossing Station 9. Punching Station

Picture 2

1. Ball Nut 2. Butterfly Spring 3. Embossing Cover Plate 4. Adjusting Nut 5. Embossing Guide Pillar 6. Embossing Guide Sleeve 7. Embossing Guide Plate 8. Protective Cover 9. Embossing Box 10. Clamp Handle 11. Handle1 12. Handle2 13. Embossing Upper Plate 14. Embossing Upper Mold 15. Embossing Lower Mold 16. Embossing Lower Plate