#Product Trends

Braided texturized fiberglass tubing

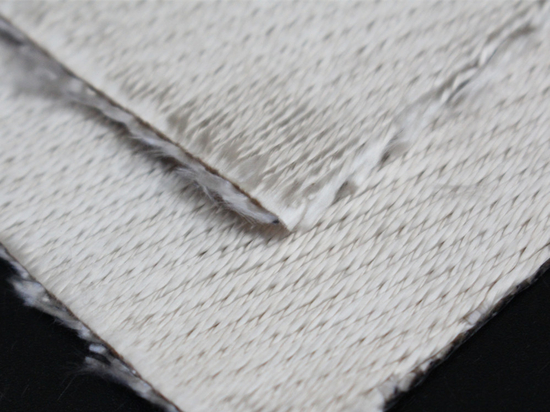

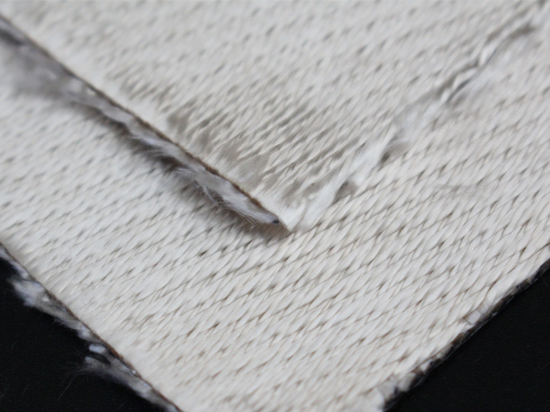

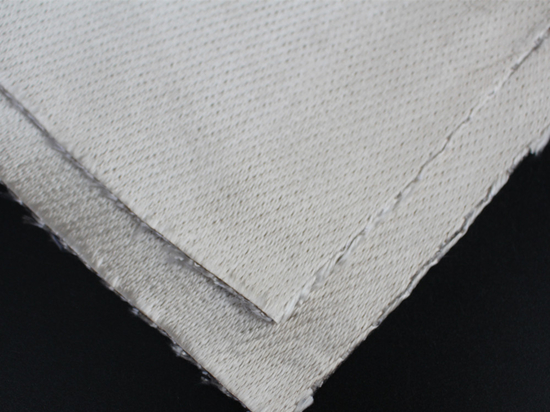

Fiberglass Sleeving

Braided texturized fiberglass tubing is a specialized material used in various industrial applications due to its unique properties. Here's a detailed look at its features, applications, and benefits:

Features

Braided Construction: The tubing is made by braiding fiberglass yarns, which enhances its mechanical strength and flexibility.

Texturized Fiberglass: The fibers are texturized, giving them a fluffy, voluminous structure that provides better insulation and higher heat resistance.

High-Temperature Resistance: Fiberglass tubing can typically withstand temperatures up to 1,000°F (538°C) or higher, depending on the specific material composition.

Electrical Insulation: It offers excellent electrical insulation properties, making it suitable for protecting wires and cables.

Chemical Resistance: The material is resistant to most chemicals, making it ideal for use in harsh environments.

Low Thermal Conductivity: This helps in maintaining the temperature within the tubing, protecting sensitive components from heat damage.

Applications

Electrical Insulation: Used to insulate wires and cables in high-temperature environments.

Heat Protection: Protects hoses, pipes, and other components from heat damage in automotive, aerospace, and industrial applications.

Chemical Processing: Used in chemical plants and refineries due to its resistance to chemicals and high temperatures.

Marine Industry: Employed in marine environments for its durability and resistance to saltwater corrosion.

Fire Safety: Acts as a protective barrier in fire safety equipment and systems.

Benefits

Durability: The braided structure and fiberglass material provide high durability and a long service life.

Flexibility: Despite its strength, the tubing remains flexible, allowing for easy installation and routing in various configurations.

Safety: Provides excellent protection against electrical and thermal hazards.

Cost-Effective: Offers a cost-effective solution for high-temperature and high-performance applications.

Considerations

When selecting braided texturized fiberglass tubing, consider the following factors:

Temperature Rating: Ensure the tubing can handle the maximum temperatures of your application.

Diameter and Length: Choose the appropriate size and length for your specific needs.

Compatibility: Verify that the tubing is compatible with any chemicals or environmental factors it will be exposed to.

Certification and Standards: Check for compliance with relevant industry standards and certifications to ensure quality and performance.