#Product Trends

Marine Exhaust Lagging Products

Exhaust Lagging

Marine exhaust lagging products are essential for protecting exhaust systems on boats, ships, and other marine vessels. These products are designed to handle the harsh, high-temperature, and corrosive marine environment, improving the performance and longevity of exhaust systems, while ensuring the safety and efficiency of onboard operations. Here are some of the key marine exhaust lagging products:

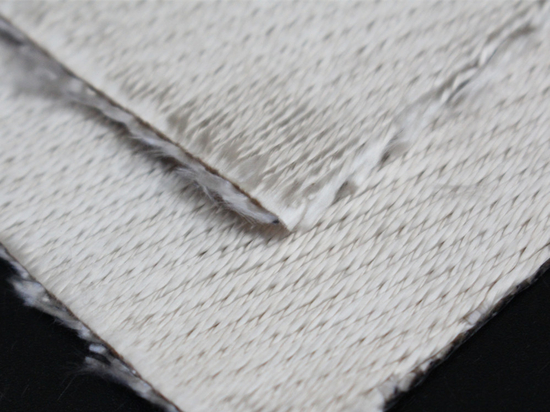

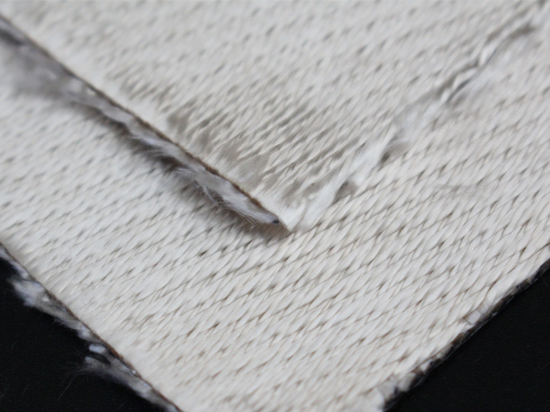

1. Marine Exhaust Wraps (Fiberglass, Basalt, or Ceramic)

Description: These wraps are designed to insulate marine exhaust pipes, reducing heat loss and preventing damage to nearby components. The insulation helps maintain optimal exhaust flow temperatures, which improves engine performance and reduces the risk of burns or fire hazards. Features:

High heat resistance (up to 1,200°F or higher)

Flexible and easy to apply

Provides noise and vibration dampening

Resists oil, water, and chemicals

UV resistant for outdoor applications

Applications: Ideal for wrapping exhaust manifolds, pipes, and turbos in marine engines.

2. Marine Exhaust Insulation Blankets

Description: Exhaust insulation blankets are made from high-quality thermal fabrics such as fiberglass, basalt, or ceramic. These blankets are designed to fit tightly around exhaust systems, providing maximum heat retention and protection. They are ideal for preventing heat from escaping and reducing the risk of damage to surrounding components. Features:

High temperature resistance (up to 1,800°F or more)

Custom fit for exhaust components

Soft, pliable material for easy installation

Offers protection from exhaust leaks and burns

Applications: Used for wrapping exhaust manifolds, turbochargers, and other high-heat components on marine engines.

3. Aluminized Exhaust Sleeving

Description: Aluminized sleeves are made from a combination of fiberglass or silica and an aluminum coating that enhances their ability to reflect heat. These sleeves offer superior protection against high temperatures, while also providing abrasion resistance and UV stability. Features:

Reflects heat away from sensitive components

Highly durable and resistant to wear and tear

Easy to install, often with Velcro closures for added convenience

Withstands high marine temperatures (up to 1,200°F)

Applications: Typically used for exhaust lines, hoses, and cables that need protection from heat and abrasion.

4. Marine Grade Silicone Coated Fiberglass Sleeving

Description: Silicone-coated fiberglass sleeving provides excellent thermal insulation for marine exhaust systems. The silicone coating adds extra flexibility and chemical resistance, making it perfect for environments where moisture and saltwater exposure are common. Features:

Excellent heat resistance (up to 500°F continuous)

Water, oil, and chemical resistant

Flexible and easy to install

Provides insulation and reduces noise

Applications: Used to protect exhaust hoses, fuel lines, and other vital systems exposed to high temperatures.

5. Basalt Fiber Exhaust Insulation

Description: Basalt fiber is an eco-friendly, high-performance material that excels in extreme temperature environments. It's ideal for marine exhaust lagging, offering superior thermal and acoustic insulation. It is also non-combustible, making it safe for high-temperature applications. Features:

Heat resistance up to 1,200°F (or higher)

High tensile strength and durability

Eco-friendly, made from volcanic rock

Offers protection against corrosion and abrasion

Applications: Ideal for wrapping exhaust pipes, manifolds, and other exhaust system components.

6. Ceramic Fiber Exhaust Wraps

Description: Ceramic fiber exhaust wraps are used for superior thermal insulation in high-performance marine engines. These wraps reduce underhood temperatures, improving engine performance and protecting other components from excessive heat. Features:

Can withstand extreme temperatures (up to 2,300°F)

Lightweight and flexible

Resistant to water and oil

Helps improve exhaust gas flow and engine efficiency

Applications: Ideal for exhaust pipes, manifolds, and turbos in high-performance marine engines.

7. Marine Exhaust Insulation Tapes

Description: High-temperature insulation tapes provide quick and easy installation around exhaust systems, offering excellent thermal protection. The tapes are often self-adhesive or can be secured with metal clips, making them a convenient option for marine exhaust lagging. Features:

Heat resistance (up to 1,200°F)

Waterproof and UV resistant

Flexible and can be used in confined spaces

Easy to install and maintain

Applications: Used for insulating exhaust manifolds and pipes, especially in tight or confined spaces.

8. Exhaust Shielding Systems

Description: Complete exhaust shielding systems provide an all-in-one solution for insulating and protecting marine exhaust components. These systems typically include insulation blankets, sleeves, wraps, and heat shields, all tailored for specific exhaust configurations. Features:

Comprehensive protection from heat and corrosion

Can be customized to fit specific engine configurations

Offers protection against fire hazards and thermal stress

Durability in challenging marine environments

Applications: Used for protecting entire exhaust systems, including manifold, piping, and turbo components.