#Industry News

Optimizing strip speed measurement for AGC/ mass flow and elongation control

Non-contact speed and length measurement in cold rolling mills

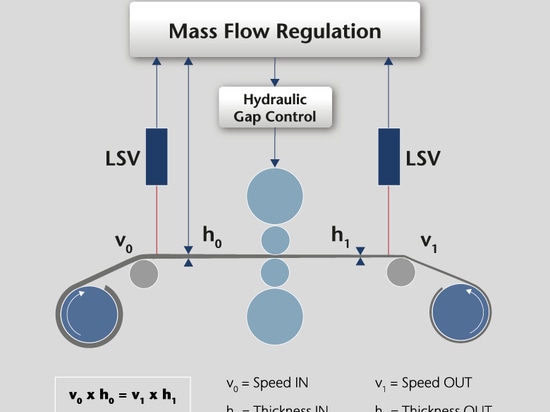

Controlling mass flow in metal production processes is the essential parameter for yield and quality. Controlling and improving mass flow means to have the width of the roll gap under control so that the material thickness of the final product remains as consistant as possible. If thickness before the roll stand and velocity before and after the roll stand are known and controlled parameters, the roll gap, which determines the thickness of the rolled product, can be adjusted in accordance with the desired conditions.

The strip thickness is measured using C-frames with an integrated, compact LSV Laser Surface Velocimeter, measuring the velocities upstream and downstream of the roll stand. Because the speed measurement is extremely accurate, you can monitor and control the roll gap more precisely using the LSV and thereby obtain better compliance with the thickness specification of the end product. The result is increased quality and, consequently, increased product output.

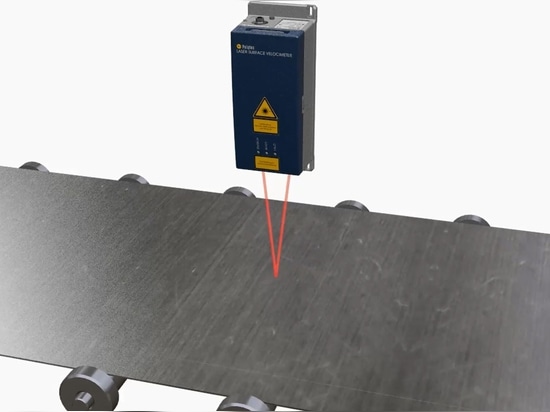

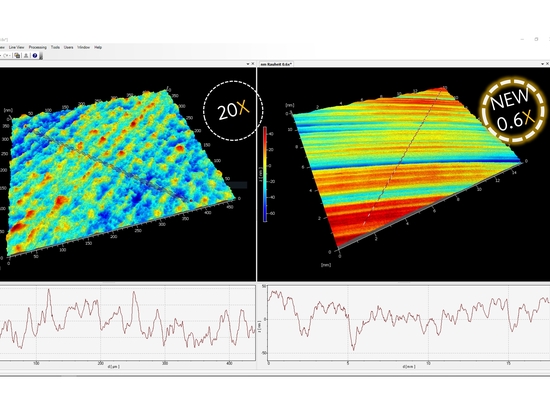

Laser optical lenght and speed sensors from Polytec measure without contact and on almost any surface, even on contaminated surfaces in industrial production environments. The non-contact laser measuring technology eliminates common issues like slippage, wear while providing the most accurate, most reliable process control without influence on the produced goods.

For further information on integrating LSV laser length and speed sensors into your production process, contact Polytec!