#Industry News

Fully-automatic noise and vibration analysis in production testing

Resonance and acoustics as quality indicator for premium components like pumps, motors, HVAC etc

Thanks to a close collaboration with one the world’s largest manufacturing companies for many years, Polytec's partners and customers have gained leading roles in their industry. Based on successful implementation of automated quality control and testing systems in laboratories and production lines, they drive their manufacturing quality for premium household appliances, providing silent and reliable motors, actuators, HVAC or pumps and more. At one of our customers, the so-called MUSA (Measurement Unit in Sound-proof Area) had become a turn-key, completely automated testing solution for their washers, integrating noise & vibration tests that are usually performed in R&D laboratories.

A complete (100 %) test on the finished products is an appropriate method to assure a high standard of quality because statistical tests on a random selection of samples cannot guarantee the quality of the full production run. It is well known that vibration tests en-able discrimination between good and faulty products and hence the analysis of the vibration signals can be used for quality control of household appliances. The technology of the Laser Doppler vibrometers (LDV) is widely used for quality control in-line or close to line where non-contact measurements are essential.

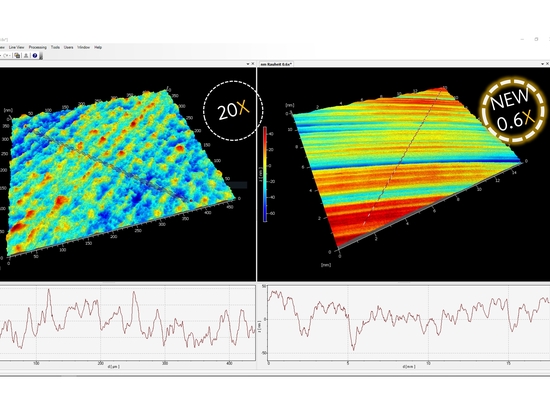

This article presents an industrial solution for the in-line monitoring of washing machines, where the use of LDV and microphones allow an objective vibro-acoustic quality inspection of the product thus detecting specific mechanical defects. The system mainly comprises a sound-proof cabinet to reduce the external noise by about 35 dB, containing three stations running simultaneously.

When the three washing machines arrive in the sound- proof cabinet, they stop in front of each station and the cabinet doors close. Each washing machine is driven to the spinning phase and the signals coming from the LDV and the microphones are acquired simultaneously, both during the run-up and the steady state.The core of the system is the signal processing software:

> Calculating the machine’s RPM directly from the LDV signal

> Filtering noise from the velocity signal

> Analyzing the laser vibrometer and microphone signals during the transient state in the time-frequency-domain (STFT)

> Evaluating the vibroemter and microphone signals during the steady state in the frequency domain

Read the full length article here.