#Industry News

Measuring the 3D topography (and dynamics!) of MEMS pressure sensors

Optical testing of MEMS pressure sensor membrane and quality control

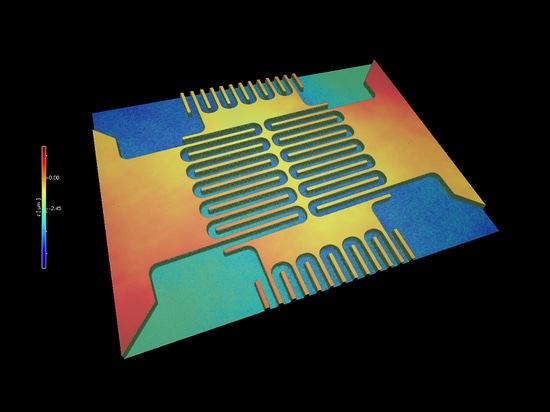

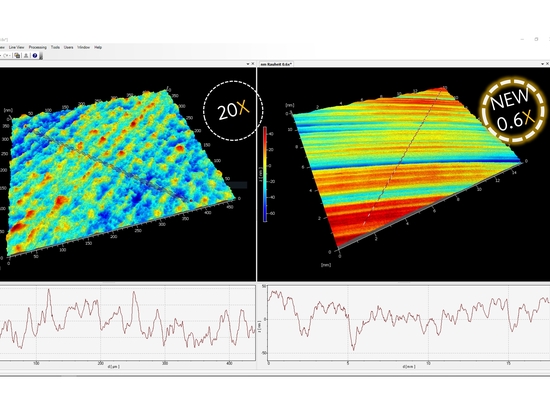

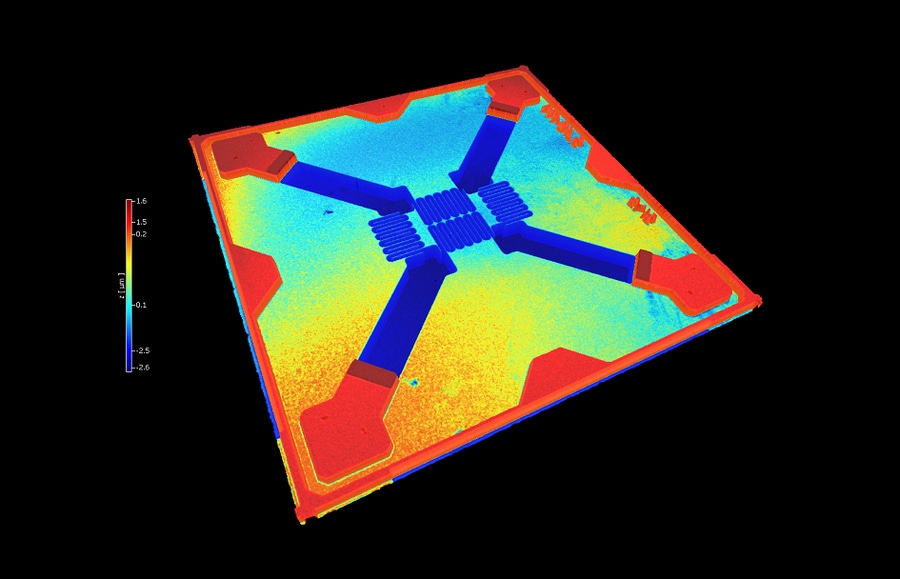

Some performance relevant parameters of pressure sensors cannot be measured electrically, which is why the industry relies on additional approaches. One such approach is 3D topography measurement of the thin and sensitive pressure sensor membrane including membrane thickness measurement. Optical surface profilers of the TopMap series of white-light interferometers precisely reveal form parameters and curvature of the pressure sensor membrane at different applied pressures, thus avoiding unwanted stress and ensuring that the etching process works as desired. Resistors applied to the pressure sensor membrane can be measured as well to confirm and optimize the positioning and attachment.

The resonance frequency and vibration amplitude of MEMS pressure sensor membrane can be detected precisely using microscope-based laser Doppler vibrometry. For each resonance the operational deflection shape of the membrane can be compared with the predicted mode shapes of a finite elements (FE) simulation. When combining the vibrometer measurement data with FE simulation data, the correlation allows to determine parameters such as boundary conditions, thickness, stiffness and stress.