#Product Trends

Laser thickness measurement with LTM

Modern laser measuring technology & Intuitive operating software

Regardless of whether it concerns rolling, blanking lines, forming lines, etc. - controlling the material thickness or maintaining the specified tolerances has become an unavoidable parameter for ensuring product quality in many areas.

ROLAND ELECTRONIC has dedicated to this task and offers a wide range of systems that fulfill this requirement with its "LTM thickness gauging systems".

Modern laser measuring technology

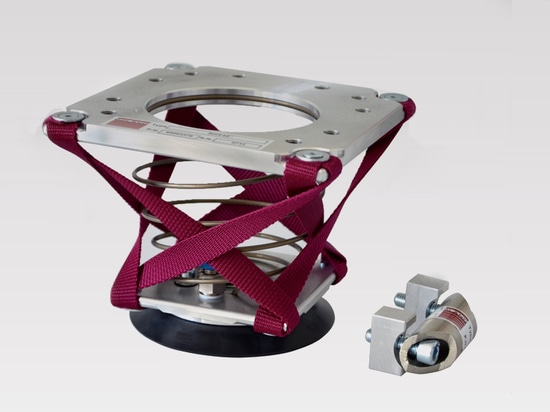

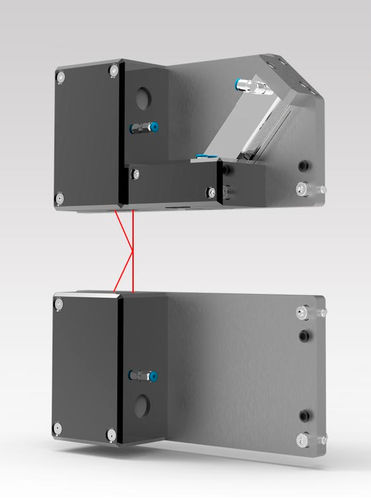

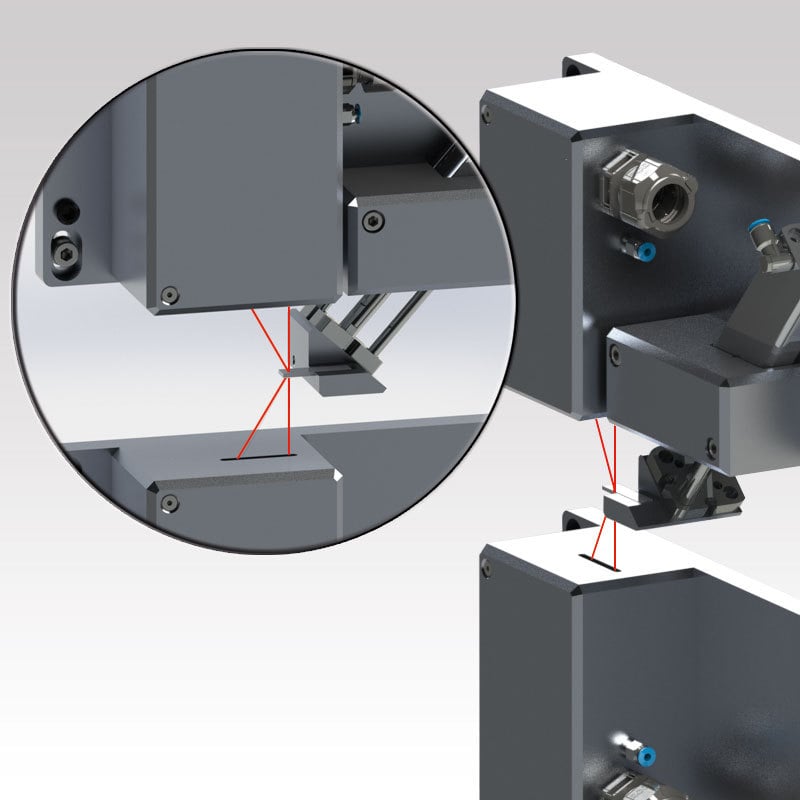

The thickness measurement is non-contacting by means of the state-of-the-art laser technology with laser triangulation sensors. The LTM belt thickness measuring system has been specially developed for high-speed strip material (ferrous and non-ferrous metals) and guarantees a measurement accuracy of up to ± 5 µm, depending on the device version. In traversing operation, the combination of thickness measurement and cross profile measurement (used as a multiple trace measurement) yields extensive quality information about the material quality.

Intuitive operating software

Within the HMI user interface, the user can easily switch between the individual views in order to display the measured values in a large format, as a stylized cross profile or as a trend graph. The target specifications, tolerances and limit values as well as the track widths can be entered directly to the interface. The tolerances of the strip thickness to be measured are stored as default values according to

DIN 10051: 2011-02. The complete order data with the parameters can be saved and archived as desired. The order-related measurement data can be saved directly as a CSV file. With standard software, e.g. the spreadsheet software Microsoft Excel or even database systems such as Oracle or MySQL, the CSV files can be further processed.