#Industry News

Exploring the Advancements in Camera Module Bonding Adhesive Technology

Best Camera Module Bonding Adhesive Glue Manufacturer

Camera module bonding adhesive technology plays a crucial role in the manufacturing of modern devices such as smartphones, tablets, and digital cameras. This technology involves the use of advanced adhesives to securely bond camera modules to the device’s circuit board, ensuring proper alignment and functionality. The importance of this technology cannot be overstated, as it directly impacts the image quality and overall performance of these devices.

In this article, we will explore the evolution of camera module bonding adhesive technology, advancements in adhesive materials, the impact on image quality, challenges and limitations, future trends, and applications in various industries.

The Evolution of Camera Module Bonding Adhesive Technology

In the early days of camera module manufacturing, traditional methods such as soldering and mechanical fasteners were used to attach camera modules to circuit boards. However, these methods had limitations in terms of alignment accuracy, durability, and overall performance. As technology advanced and devices became smaller and more complex, the need for a more reliable and efficient bonding method became apparent.

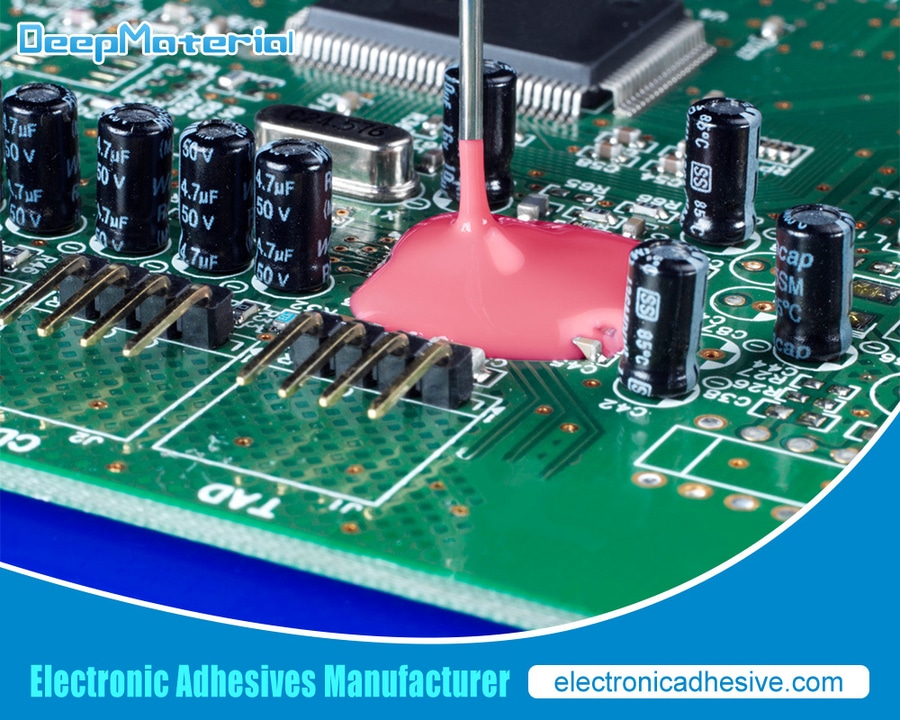

Advancements in adhesive technology have revolutionized the camera module bonding process. The introduction of specialized adhesives specifically designed for camera module bonding has allowed for precise alignment, improved durability, and enhanced performance. These adhesives are formulated to withstand extreme temperatures, humidity, and mechanical stress, ensuring that the camera module remains securely attached to the circuit board even in challenging conditions.

Advancements in Camera Module Bonding Adhesive Technology

There are several types of adhesives used in camera module bonding, including epoxy-based adhesives, acrylic-based adhesives, and UV-curable adhesives. Each type has its own unique properties and advantages. Epoxy-based adhesives are known for their high strength and excellent chemical resistance. Acrylic-based adhesives offer good adhesion to a wide range of substrates and have excellent resistance to environmental factors. UV-curable adhesives provide fast curing times and high bond strength.

In recent years, there have been significant advancements in adhesive technology for camera module bonding. One notable development is the introduction of conductive adhesives, which allow for the integration of electrical connections within the adhesive layer. This eliminates the need for separate wire bonding or soldering, resulting in a more compact and efficient design.

Another advancement is the use of flexible adhesives, which can accommodate the bending and flexing of the device without compromising the bond strength. This is particularly important in devices with foldable or curved screens, where traditional rigid adhesives may fail.

The benefits of using advanced adhesives in camera module bonding are numerous. These adhesives provide excellent adhesion strength, ensuring that the camera module remains securely attached to the circuit board even under extreme conditions. They also offer improved alignment accuracy, resulting in better image quality and overall performance. Additionally, advanced adhesives can withstand high temperatures, humidity, and mechanical stress, making them ideal for use in a wide range of applications.

The Impact of Camera Module Bonding Adhesive Technology on Image Quality

Camera module bonding adhesive technology has a direct impact on the image quality of modern devices. The alignment accuracy and stability provided by advanced adhesives ensure that the camera module remains in the correct position relative to the lens and sensor, resulting in sharper and more accurate images.

Furthermore, the use of advanced adhesives can help to reduce the impact of external factors on image quality. Dust and moisture can degrade image quality by affecting the lens or sensor. The use of adhesive materials that provide a barrier against these elements can help to maintain the performance of the camera module over time.

Examples of how advanced adhesives have improved image quality in modern devices can be seen in smartphones. The use of high-quality adhesives in smartphone camera modules has resulted in significant improvements in low-light performance, color accuracy, and overall image sharpness. These advancements have made smartphone cameras capable of producing professional-quality images, rivaling dedicated digital cameras.

Challenges and Limitations of Camera Module Bonding Adhesive Technology

While camera module bonding adhesive technology has come a long way, there are still challenges and limitations that need to be addressed. One common challenge is the need for precise alignment during the bonding process. Any misalignment can result in degraded image quality or even complete failure of the camera module. Manufacturers must invest in advanced equipment and processes to ensure accurate alignment.

Another challenge is the durability of the adhesive bond over time. Devices are subjected to various environmental factors such as temperature changes, humidity, and mechanical stress. The adhesive must be able to withstand these conditions without degrading or losing its bond strength. Ongoing research and development are needed to improve the durability of adhesive materials.

Additionally, there are limitations to the current adhesive technology. For example, some adhesives may not be suitable for use in certain applications due to their temperature resistance or compatibility with specific substrates. Manufacturers must carefully select the appropriate adhesive for each application to ensure optimal performance.

Future Trends in Camera Module Bonding Adhesive Technology

The future of camera module bonding adhesive technology looks promising, with several trends and advancements on the horizon. One potential area of development is the use of nanomaterials in adhesive formulations. Nanomaterials offer unique properties such as high strength, flexibility, and thermal conductivity, which can enhance the performance of camera module bonding.

Another trend is the integration of additional functionalities within the adhesive layer. For example, researchers are exploring the use of adhesive materials that can act as thermal conductors or electromagnetic shields, further improving the overall performance of the device.

Furthermore, advancements in manufacturing processes such as additive manufacturing and 3D printing may revolutionize camera module bonding. These technologies have the potential to create complex adhesive structures with precise alignment and customized properties, opening up new possibilities for device design and performance.

Final Thoughts

In conclusion, camera module bonding adhesive technology plays a crucial role in the manufacturing of modern devices. Advancements in adhesive materials have revolutionized the camera module bonding process, resulting in improved image quality, durability, and overall performance. The use of advanced adhesives ensures precise alignment, reduces the impact of external factors, and enhances the overall user experience.

For more about choosing the electronic adhesive, you can pay a visit to DeepMaterial at https://www.electronicadhesive.com/product/ for more info.