#Industry News

Exploring The Versatility of Industrial Bonding Adhesive: A Comprehensive Guide

Best Industrial Bonding Adhesive Glue Manufacturer

Industrial bonding adhesive plays a crucial role in various industries, providing a strong and durable bond between different materials. Whether it’s in the automotive, aerospace, construction, or electronics industry, industrial bonding adhesive is essential for joining components together.

This article will provide an in-depth understanding of industrial bonding adhesive, its types, advantages over traditional adhesives, applications in different industries, factors to consider when choosing the right adhesive, surface preparation techniques, application techniques, testing and quality control, maintenance and repair of adhesive joints, and future developments in adhesive technology.

Types of Industrial Bonding Adhesive

There are several types of industrial bonding adhesive available in the market, each with its own unique characteristics and properties. Some common types include epoxy adhesives, acrylic adhesives, polyurethane adhesives, and cyanoacrylate adhesives.

Epoxy adhesives are known for their high strength and excellent chemical resistance. They are commonly used in industries such as aerospace and automotive, where strong and durable bonds are required. Acrylic adhesives, on the other hand, offer fast curing times and good resistance to environmental factors such as UV light and moisture. They are often used in the electronics industry for bonding components together.

Polyurethane adhesives provide excellent flexibility and impact resistance, making them suitable for applications that require some degree of movement or vibration. They are commonly used in the construction industry for bonding materials such as wood, metal, and plastic. Cyanoacrylate adhesives, also known as super glue, offer fast curing times and high bond strength. They are widely used in various industries for bonding small components together.

Advantages of Industrial Bonding Adhesive over Traditional Adhesives

Industrial bonding adhesive offers several advantages over traditional adhesives such as mechanical fasteners or welding. One of the main advantages is the ability to bond different materials together, including dissimilar materials. This allows for greater design flexibility and the ability to create lightweight structures. Traditional adhesives often have limitations when it comes to bonding different materials, whereas industrial bonding adhesive can bond materials such as metal to plastic or glass to wood.

Another advantage of industrial bonding adhesive is the ability to distribute stress evenly across the joint, resulting in a stronger and more durable bond. Traditional adhesives often create stress concentrations at the edges of the joint, which can lead to premature failure. Industrial bonding adhesive, on the other hand, forms a continuous bond that distributes stress more evenly, resulting in a stronger and more reliable joint.

Furthermore, industrial bonding adhesive offers improved aesthetics compared to traditional adhesives. Traditional adhesives such as mechanical fasteners or welding often leave visible marks or distortions on the surface of the materials being joined. Industrial bonding adhesive, on the other hand, creates a seamless bond that is virtually invisible, resulting in a cleaner and more aesthetically pleasing finish.

Applications of Industrial Bonding Adhesive in Various Industries

Industrial bonding adhesive finds applications in a wide range of industries, including automotive, aerospace, construction, electronics, and medical. In the automotive industry, industrial bonding adhesive is used for bonding components such as body panels, interior trim, and structural components. It provides a strong and durable bond that can withstand the harsh conditions of the road.

In the aerospace industry, industrial bonding adhesive is used for bonding components such as aircraft panels, wings, and fuselage. It provides a lightweight and strong bond that can withstand the extreme conditions of flight. In the construction industry, industrial bonding adhesive is used for bonding materials such as glass, metal, and plastic. It provides a strong and durable bond that can withstand the elements.

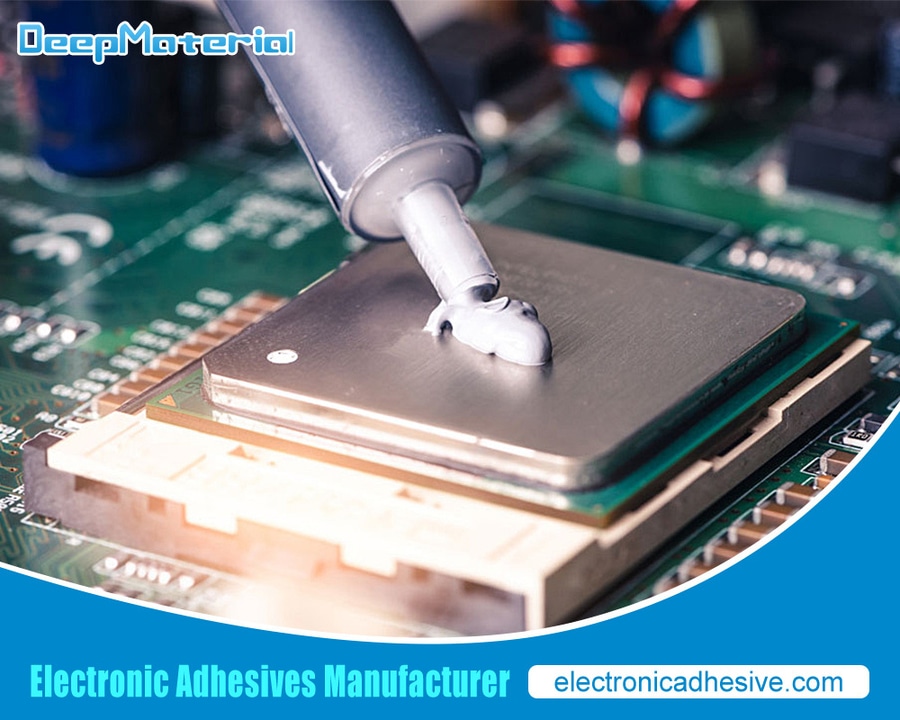

In the electronics industry, industrial bonding adhesive is used for bonding components such as circuit boards, connectors, and displays. It provides a fast and reliable bond that can withstand the demands of electronic devices. In the medical industry, industrial bonding adhesive is used for bonding components such as medical devices, implants, and prosthetics. It provides a biocompatible and sterile bond that is safe for use in the human body.

Maintenance and Repair of Industrial Bonding Adhesive Joints

Proper maintenance and repair of industrial bonding adhesive joints are important for ensuring their long-term performance and reliability. Regular inspection should be carried out to identify any signs of damage or deterioration, such as cracks, delamination, or discoloration. Any issues should be addressed promptly to prevent further damage or failure.

In some cases, it may be necessary to repair or replace the adhesive joint. This can be done by removing the damaged adhesive and reapplying a new adhesive. The surfaces should be properly prepared before applying the new adhesive to ensure a strong and durable bond. It’s important to follow the manufacturer’s instructions for the specific adhesive being used and to allow sufficient curing time before subjecting the joint to any load or stress.

Future Developments in Industrial Bonding Adhesive Technology

The field of industrial bonding adhesive is constantly evolving, with ongoing research and development aimed at improving the performance and versatility of adhesives. One area of research is the development of adhesives with enhanced properties, such as improved bond strength, faster curing times, and greater resistance to environmental factors.

Another area of research is the development of adhesives that are more environmentally friendly. This includes the use of bio-based materials or the development of adhesives that can be easily recycled or disposed of without causing harm to the environment.

Furthermore, there is ongoing research into the development of smart adhesives that can sense and respond to changes in their environment. This includes the development of adhesives that can self-heal or repair themselves when damaged, or adhesives that can change their properties in response to external stimuli such as temperature or humidity.

These advancements in adhesive technology have the potential to revolutionize various industries, providing new opportunities for design and manufacturing. They can also contribute to more sustainable and environmentally friendly practices, reducing waste and energy consumption.

Conclusion

Industrial bonding adhesive plays a crucial role in various industries, providing a strong and durable bond between different materials. It offers several advantages over traditional adhesives, including the ability to bond different materials together, distribute stress evenly across the joint, and provide improved aesthetics. Industrial bonding adhesive finds applications in industries such as automotive, aerospace, construction, electronics, and medical.