#Industry News

Common Issues with Electronic Epoxy Encapsulant Potting Compounds

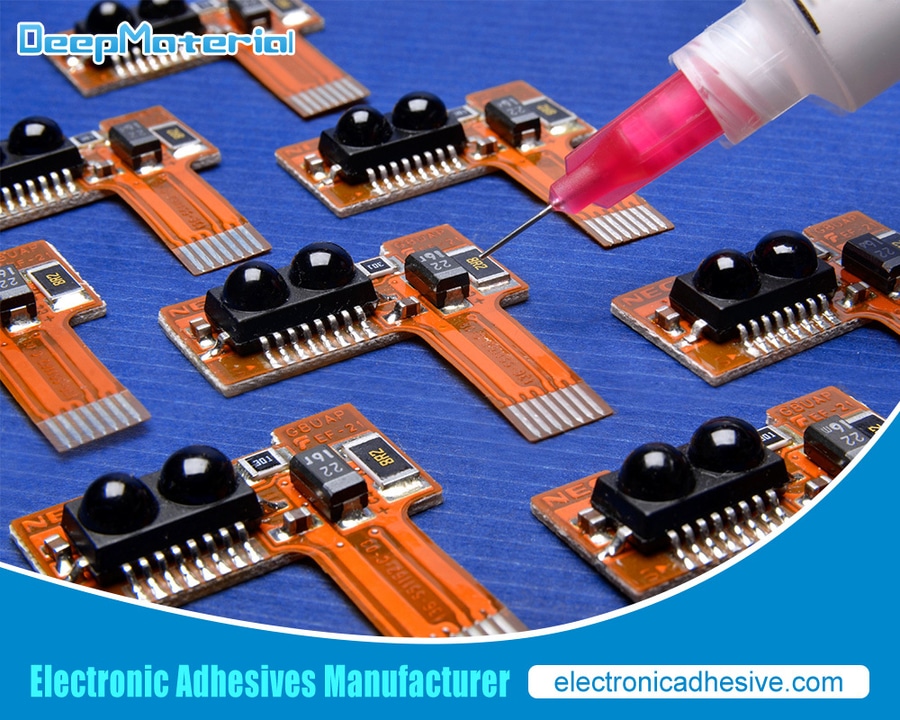

Best Electronic Adhesive Glue Encapsulant Potting Compounds Manufacturer

While electronic epoxy encapsulant potting compounds offer many benefits, they can also encounter various issues that can affect their performance. Some common issues include poor adhesion, incomplete curing, shrinkage, and cracking. These issues can compromise the effectiveness of the potting compound and lead to failures in the electronic device.

Poor adhesion is a common issue with potting compounds and can result in delamination or detachment of the compound from the electronic component. This can occur due to improper surface preparation, contamination, or incompatibility between the potting compound and the substrate. Incomplete curing is another issue that can occur when the potting compound does not fully harden or cure. This can be caused by factors such as incorrect mixing ratios, insufficient curing time, or improper curing conditions.

Shrinkage is another common issue with potting compounds and can result in stress on the electronic components. Shrinkage occurs when the potting compound undergoes a volume reduction during the curing process. This can lead to mechanical stress on the components and potentially cause damage or failure. Cracking is another issue that can occur with potting compounds and can be caused by factors such as excessive shrinkage, thermal cycling, or mechanical stress.

Understanding the Causes of Potting Compound Failures

To effectively troubleshoot and prevent potting compound failures, it is important to understand the factors that contribute to these issues. Several factors can contribute to potting compound failures, including improper surface preparation, contamination, incorrect mixing ratios, insufficient curing time, improper curing conditions, excessive shrinkage, thermal cycling, and mechanical stress.

Environmental factors can also affect the performance of potting compounds. Exposure to high temperatures, humidity, chemicals, and UV radiation can degrade the potting compound over time and lead to failures. It is important to consider the operating conditions and environmental factors when selecting a potting compound to ensure its compatibility and durability.

How to Identify Potting Compound Failures

Identifying potting compound failures is crucial for troubleshooting and resolving issues in electronic devices. There are several signs that can indicate potting compound failures, including delamination or detachment of the compound from the substrate, soft or sticky areas in the cured compound, incomplete curing or tackiness, shrinkage or cracks in the compound, and discoloration or degradation of the compound.

To identify potting compound failures, various methods can be used. Visual inspection can help identify signs of delamination, shrinkage, cracks, or discoloration. Mechanical testing, such as pull tests or shear tests, can assess the adhesion strength of the potting compound. Thermal analysis techniques, such as differential scanning calorimetry (DSC) or thermogravimetric analysis (TGA), can provide information about the curing behavior and thermal stability of the potting compound.

Tips for Preventing Potting Compound Failures

Preventing potting compound failures requires following best practices and taking precautions during the potting process. Some tips for preventing potting compound failures include:

Proper surface preparation: Ensure that the substrate is clean, dry, and free from contaminants before applying the potting compound. This can be achieved through thorough cleaning and surface treatment, such as sanding or degreasing.

Correct mixing ratios: Follow the manufacturer’s instructions for mixing the potting compound to ensure the correct ratio of resin and hardener. Incorrect mixing ratios can result in incomplete curing or poor adhesion.

Sufficient curing time: Allow the potting compound to cure for the recommended time to ensure complete hardening. Avoid rushing the curing process, as this can lead to incomplete curing and reduced performance.

Proper curing conditions: Maintain the recommended curing temperature and humidity conditions during the curing process. Deviating from the recommended conditions can affect the curing behavior and performance of the potting compound.

Compatibility testing: Before applying the potting compound, perform compatibility testing to ensure that it is compatible with the substrate and other materials in the electronic device. This can help prevent issues such as poor adhesion or chemical incompatibility.

Consider environmental factors: Take into account the operating conditions and environmental factors that the electronic device will be exposed to. Select a potting compound that is suitable for these conditions to ensure long-term durability and performance.

Troubleshooting Potting Compound Adhesion Issues

Poor adhesion is a common issue with potting compounds and can result in delamination or detachment of the compound from the substrate. Several factors can contribute to poor adhesion, including improper surface preparation, contamination, incompatibility between the potting compound and the substrate, and inadequate curing conditions.

To troubleshoot adhesion issues, it is important to ensure proper surface preparation. Thoroughly clean and dry the substrate before applying the potting compound to remove any contaminants that could interfere with adhesion. Surface treatment, such as sanding or degreasing, can also improve adhesion by creating a rougher surface for the potting compound to adhere to.

Contamination can also affect adhesion, so it is important to ensure that the potting compound and all tools and equipment used during the potting process are clean and free from contaminants. Incompatibility between the potting compound and the substrate can also lead to poor adhesion. Perform compatibility testing to ensure that the potting compound is suitable for the substrate and other materials in the electronic device.

Conclusion and Best Practices for Electronic Epoxy Encapsulant Potting Compounds

In conclusion, electronic epoxy encapsulant potting compounds are essential for protecting and insulating electronic components and devices. However, they can encounter various issues that can affect their performance. Understanding the causes of potting compound failures and implementing best practices can help prevent these issues and ensure the long-term durability and performance of electronic devices.

Some best practices for using potting compounds include proper surface preparation, correct mixing ratios, sufficient curing time, proper curing conditions, compatibility testing, and considering environmental factors. Troubleshooting adhesion issues, curing issues, shrinkage issues, and cracking issues requires addressing the underlying causes and implementing appropriate solutions.

By following these best practices and troubleshooting techniques, electronic device manufacturers can ensure the effective use of potting compounds and enhance the reliability and performance of their products.