#Industry News

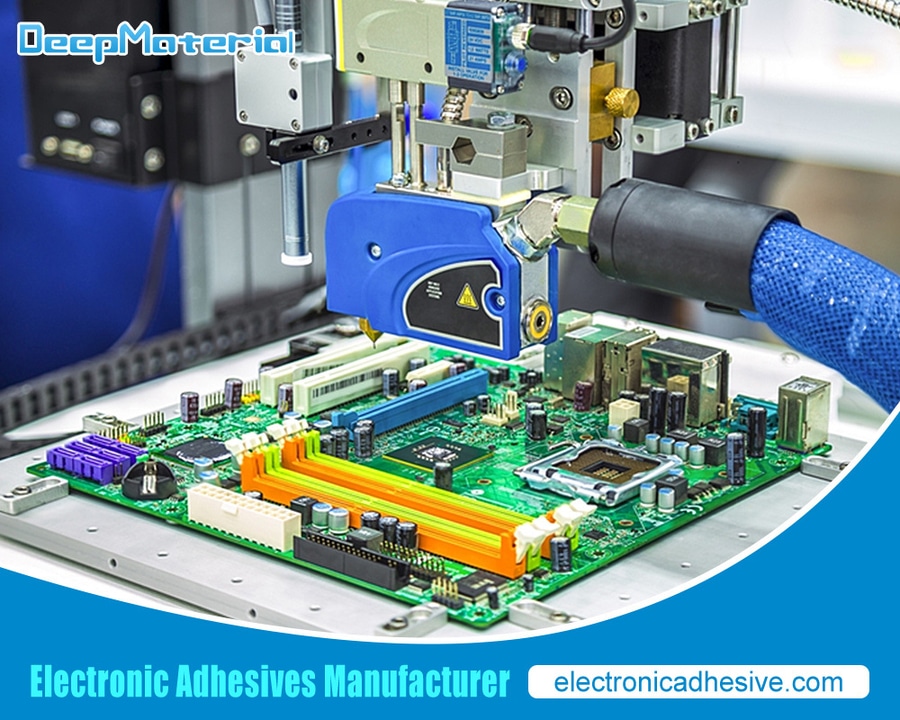

Electronics Assembly Adhesives: A Comprehensive Guide

Best Electronic Adhesive Glue Manufacturer

Introduction to Electronics Assembly Adhesives

In the rapidly evolving field of electronics, the demand for reliable, efficient, and durable assembly solutions has never been higher. Electronics assembly adhesives play a crucial role in ensuring the integrity and performance of electronic devices, from consumer electronics like smartphones and laptops to sophisticated industrial and medical equipment. These adhesives are formulated to meet the specific needs of electronic components, providing essential properties such as electrical insulation, thermal conductivity, and environmental resistance.

Types of Electronics Assembly Adhesives

Electronics assembly adhesives come in various forms, each tailored to specific applications and performance requirements. Understanding the different types of adhesives available can help you select suitable ones for a particular application.

Epoxy Adhesives

Epoxy adhesives are widely used in electronics assembly due to their excellent mechanical strength, chemical resistance, and electrical insulation properties. They are available in one-part and two-part formulations. One-part epoxies are cured with heat, while two-part epoxies are cured at room temperature upon mixing. Epoxies are ideal for bonding metals, plastics, and ceramics and provide robust performance in harsh environments.

Acrylic Adhesives

Acrylic adhesives are known for their fast curing times and high bond strength. They resist environmental factors such as moisture, temperature fluctuations, and UV light. Acrylics are often used in applications where quick assembly and high productivity are essential. They are suitable for bonding a variety of substrates, including metals, plastics, and glass.

Silicone Adhesives

Silicone adhesives are prized for their flexibility, high-temperature resistance, and excellent dielectric properties. They are commonly used in applications where components are subjected to thermal cycling and mechanical stress. Silicones maintain their performance over a wide temperature range and effectively seal against moisture and contaminants.

Polyurethane Adhesives

Polyurethane adhesives offer a good balance of flexibility and strength. They are instrumental in applications where substrates undergo differential thermal expansion. Polyurethanes provide good adhesion to various materials and exhibit excellent resistance to impact and vibration, making them suitable for automotive and aerospace electronics.

Conductive Adhesives

Conductive adhesives are formulated with conductive fillers such as silver or carbon to provide electrical conductivity. They are used in applications where soldering is not feasible or heat-sensitive components must be bonded. Conductive adhesives are essential in forming electrical connections and shielding against electromagnetic interference (EMI).

Critical Properties of Electronics Assembly Adhesives

When selecting an adhesive for electronics assembly, several critical properties must be considered to ensure optimal performance and reliability of the final product.

Electrical Insulation

Adhesives must provide excellent electrical insulation for many electronic applications to prevent short circuits and electrical leakage. Epoxy and silicone adhesives are commonly used for their superior insulating properties.

Thermal Conductivity

Effective heat dissipation is vital in electronic devices to prevent overheating and ensure longevity. Thermally conductive adhesives, which typically contain fillers like aluminum oxide or boron nitride, are used to bond heat sinks and other components to enhance heat transfer.

Mechanical Strength

The adhesive must provide sufficient mechanical strength to withstand vibration, impact, and thermal cycling. Epoxy and acrylic adhesives are known for their high bond strength and durability.

Flexibility

Flexibility is essential in applications where components experience movement or differential expansion due to temperature changes. Silicone and polyurethane adhesives offer the necessary elasticity to accommodate these conditions without cracking or delaminating.

Chemical and Environmental Resistance

Electronics are often exposed to harsh environments, including moisture, chemicals, and extreme temperatures. Adhesives must resist these factors to maintain their performance and protect the components they bond.

Fast Curing

In high-volume manufacturing, fast-curing adhesives are preferred to increase production efficiency. UV-curable and some acrylic adhesives offer rapid curing times, enabling quicker assembly processes.

Applications of Electronics Assembly Adhesives

Electronics assembly adhesives are used in various applications across various industries. Here are some of the critical applications:

Consumer Electronics

Adhesives are used in consumer electronics to assemble and protect components in devices such as smartphones, tablets, laptops, and wearables. They provide bonding, sealing, and encapsulation solutions to enhance the durability and performance of these devices.

Automotive Electronics

The automotive industry relies heavily on adhesives for assembling electronic vehicle components, including sensors, control units, and infotainment systems. Adhesives must withstand the harsh conditions of the automotive environment, such as temperature extremes, vibration, and exposure to chemicals.

Aerospace and Defense

In aerospace and defense applications, adhesives bond and seal components in avionics, communication systems, and sensors. These adhesives must meet stringent performance standards and provide reliability under extreme conditions.

Medical Devices

Medical devices often incorporate adhesives in assembling diagnostic equipment, monitoring devices, and implants. Biocompatibility, sterilization resistance, and reliability are critical factors for adhesives used in medical applications.

Industrial Electronics

Adhesives assemble control systems, sensors, and power electronics in industrial electronics. They must perform robustly in demanding environments, including chemical exposure, moisture, and mechanical stress.

Renewable Energy

Adhesives are used to bond and seal components in the renewable energy sector, including solar panels and wind turbines. These adhesives must provide long-term durability and resistance to environmental factors such as UV radiation and moisture.

Challenges and Innovations in Electronics Assembly Adhesives

The field of electronics assembly adhesives is continually evolving, driven by the need for more advanced and reliable bonding solutions. However, several challenges persist, prompting ongoing research and innovation.

Miniaturization

As electronic devices become smaller and more compact, the need for adhesives that can provide precise application and strong bonding in confined spaces increases. Innovations in dispensing techniques and adhesive formulations are addressing these challenges.

Heat Management

With electronic devices’ increasing power density, effective heat management is crucial. Innovations in thermally conductive adhesives focus on enhancing thermal conductivity while maintaining electrical insulation and mechanical strength.

Environmental Sustainability

The electronics industry is under growing pressure to adopt environmentally sustainable practices. This includes using adhesives free from hazardous substances that can be processed with minimal environmental impact. Research is ongoing to develop eco-friendly adhesive formulations.

Reliability and Performance

Adhesives must provide long-term reliability and performance under various conditions. Advances in material science are leading to the development of adhesives with improved resistance to thermal cycling, moisture, and mechanical stress.

Ease of Application

Adhesives that offer easy application and fast curing are highly desirable to streamline the manufacturing process. Innovations in UV-curable and one-part adhesive formulations enable quicker and more efficient assembly processes.

Future Trends in Electronics Assembly Adhesives

The future of electronics assembly adhesives is poised for exciting developments as technology advances. Here are some trends to watch:

Smart Adhesives

Innovative adhesives that can change properties in response to environmental stimuli such as temperature or moisture are being explored. These adhesives could offer dynamic performance and adaptability in various applications.

Nanotechnology

Integrating nanotechnology in adhesive formulations opens new possibilities for enhanced properties such as improved thermal conductivity, electrical conductivity, and mechanical strength.

Bio-based Adhesives

The development of bio-based adhesives from renewable sources is gaining traction. These adhesives aim to reduce the environmental impact of electronic manufacturing and align with sustainability goals.

Advanced Dispensing Techniques

Innovations in dispensing techniques, such as precision jet dispensing and automated robotic systems, are improving the accuracy and efficiency of adhesive application in electronics assembly.

Enhanced Thermal Management

As electronic devices generate more heat, the demand for adhesives with superior thermal management capabilities will increase. Future adhesives will likely offer higher thermal conductivity and improved heat dissipation properties.

Conclusion

Electronics assembly adhesives are essential components in the manufacturing of modern electronic devices. Their role in providing reliable bonding, electrical insulation, thermal management, and environmental protection cannot be overstated. With ongoing advancements in adhesive technology, the future holds promise for even more efficient, sustainable, high-performance solutions. Understanding the types, properties, and applications of electronic assembly adhesives is crucial for selecting the suitable adhesive for each specific application, ensuring the longevity and reliability of electronic devices in an ever-evolving technological landscape.

For more about choosing the Electronics Assembly Adhesives: A Comprehensive Guide, you can pay a visit to DeepMaterial at https://www.electronicadhesive.com/ for more info.