#Industry News

Best Korean Manufacturers of Industrial Epoxy Adhesive Glue

Best Industrial Epoxy Adhesive Glue Manufacturer

South Korea, often regarded as a technological powerhouse, is also a significant player in the global industrial adhesive market. The country’s innovations, backed by solid research and development, have made it a leader in producing high-quality epoxy adhesives. These adhesives are essential in various industries, such as automotive, electronics, aerospace, and construction, owing to their exceptional bonding strength, durability, and resistance to environmental factors. In this article, we will delve into what makes the best industrial epoxy adhesive glue manufacturers in Korea stand out, explore the different applications of epoxy adhesives, and highlight the features and benefits that make them a preferred choice in numerous sectors.

Critical Properties of Epoxy Adhesives

Epoxy adhesives are favored in industrial applications due to their remarkable properties:

High Bond Strength: Epoxy adhesives offer unparalleled bonding strength, making them suitable for heavy-duty applications.

Chemical Resistance:They resist degradation by chemicals, oils, and other solvents, maintaining their integrity in harsh environments.

Temperature Resistance: Epoxy adhesives can withstand extreme temperatures, making them suitable for heat exposure applications.

Durability: Their long-lasting performance makes them ideal for structural applications where reliability is critical.

Versatility: These adhesives can bond with various materials, including metals, plastics, ceramics, and composites.

Why Choose Korean Epoxy Adhesive Manufacturers?

Korean manufacturers of industrial epoxy adhesives are recognized for their commitment to quality, innovation, and customer satisfaction. Here are several reasons why these manufacturers are considered some of the best in the industry:

Advanced Research and Development

Korean manufacturers invest heavily in research and development to stay ahead in the competitive market. This focus on innovation leads to the creation of high-performance epoxy adhesives tailored to meet the specific needs of various industries.

State-of-the-Art Manufacturing Facilities

Korean manufacturers produce the highest-quality epoxy adhesives equipped with cutting-edge technology and machinery. These facilities adhere to strict quality control measures to ensure product consistency and reliability.

Customized Solutions

Korean epoxy adhesive manufacturers understand that different industries have unique requirements. They offer customized solutions, working closely with clients to develop adhesives that address specific bonding challenges and operational needs.

Eco-Friendly Products

Korean manufacturers prioritize environmental sustainability. They develop eco-friendly epoxy adhesives that minimize environmental impact while maintaining high performance and comply with international environmental standards and regulations.

Robust Global Distribution Network

With a well-established global distribution network, Korean manufacturers ensure timely delivery and excellent after-sales support to customers worldwide. This global reach allows them to efficiently cater to international markets.

Applications of Industrial Epoxy Adhesive Glues

The versatility and durability of epoxy adhesives make them indispensable in various industries. Below are some of the critical applications of these adhesives:

Automotive Industry

In the automotive sector, epoxy adhesives bond components such as body panels, frames, and structural parts. They provide exceptional strength, which enhances vehicle safety and performance. Additionally, epoxy adhesives help reduce vehicle weight by eliminating the need for mechanical fasteners, improving fuel efficiency.

Electronics Industry

Epoxy adhesives play a crucial role in the electronics industry. They provide reliable bonding solutions for components like circuit boards, connectors, and sensors. They also offer excellent insulation properties, protecting electronic components from moisture, dust, and other environmental factors.

Aerospace Industry

The aerospace industry demands adhesives that can withstand extreme conditions. Epoxy adhesives bond various aircraft components, including wings, fuselage, and interior panels. Their high-temperature resistance and mechanical strength ensure the structural integrity and safety of aircraft.

Construction Industry

In the construction industry, epoxy adhesives bond concrete, steel, and other building materials. They provide strong, durable bonds that contribute to the stability and longevity of structures. Epoxy adhesives are also used to repair cracks and reinforce structural elements.

Marine Industry

Epoxy adhesives are widely used in the marine industry for boat building and repairs. They provide excellent water resistance and durability, ensuring boats and ships can withstand harsh marine environments.

Renewable Energy Sector

Epoxy adhesives are used in the production of wind turbines and solar panels in the renewable energy sector. They offer strong bonding solutions that enhance the durability and performance of these energy systems.

Features and Benefits of Korean Industrial Epoxy Adhesives

When it comes to industrial applications, the best industrial epoxy adhesive glue manufacturer in Korea offers several features and benefits that set them apart:

Superior Adhesion

Korean epoxy adhesives are known for their superior adhesion properties, which ensure solid and reliable bonds across various substrates. This quality is essential in industries where structural integrity is paramount.

High Durability

Korean epoxy adhesives are unmatched in durability. They are designed to withstand harsh environmental conditions, including extreme temperatures, moisture, and chemical exposure, without compromising performance.

Fast Curing Times

Korean manufacturers offer epoxy adhesives with fast curing times, reducing downtime and increasing productivity. This feature is particularly beneficial in industries where time efficiency is critical.

Exceptional Flexibility

Epoxy adhesives from Korean manufacturers are formulated to provide flexibility without sacrificing strength. This flexibility allows them to accommodate the expansion and contraction of bonded materials, reducing the risk of bond failure.

Cost-Effectiveness

Despite their high performance, Korean epoxy adhesives are cost-effective solutions for industrial applications. They provide excellent value for money, offering long-lasting bonds that reduce maintenance and repair costs.

Environmental Compliance

Korean manufacturers are committed to producing epoxy adhesives that comply with environmental standards. These adhesives are formulated with low VOC (volatile organic compound) content, minimizing their impact on air quality and human health.

Key Considerations When Choosing Epoxy Adhesive Manufacturers

Selecting the proper epoxy adhesive manufacturer is crucial to ensure that the adhesive meets your specific requirements. Here are some key factors to consider when choosing a manufacturer:

Quality Assurance

Look for manufacturers with strict quality control measures and certifications, such as ISO 9001. These certifications demonstrate their commitment to producing high-quality products that meet industry standards.

Technical Support

Choose a manufacturer that offers excellent technical support and customer service. This support is essential for addressing issues arising during the application process and ensuring optimal adhesive performance.

Product Range

A manufacturer with a diverse product range can offer adhesives tailored to different industrial applications. This variety ensures you can find the suitable adhesive for your specific bonding needs.

Innovation and R&D

Manufacturers prioritizing innovation and R&D are more likely to offer advanced adhesive solutions incorporating the latest technologies and trends.

Environmental Responsibility

Consider manufacturers that prioritize environmental responsibility by producing eco-friendly adhesives. These manufacturers contribute to sustainability efforts and are committed to reducing their ecological footprint.

Future Trends in the Epoxy Adhesive Industry

The industrial epoxy adhesive market is constantly evolving, driven by technological advancements and changing industry demands. Here are some future trends to watch in the epoxy adhesive industry:

Increased Demand for Lightweight Materials

As industries such as automotive and aerospace focus on reducing weight for improved efficiency, there will be a growing demand for epoxy adhesives that bond lightweight materials like composites and plastics.

Advancements in Nanotechnology

Nanotechnology is expected to play a significant role in developing epoxy adhesives with enhanced properties. Nano-fillers can improve adhesion, thermal conductivity, and mechanical strength, leading to more robust adhesive solutions.

Emphasis on Sustainability

Sustainability will remain a key focus in the adhesive industry. Manufacturers will continue to develop eco-friendly formulations with reduced environmental impact, catering to industries prioritizing sustainability.

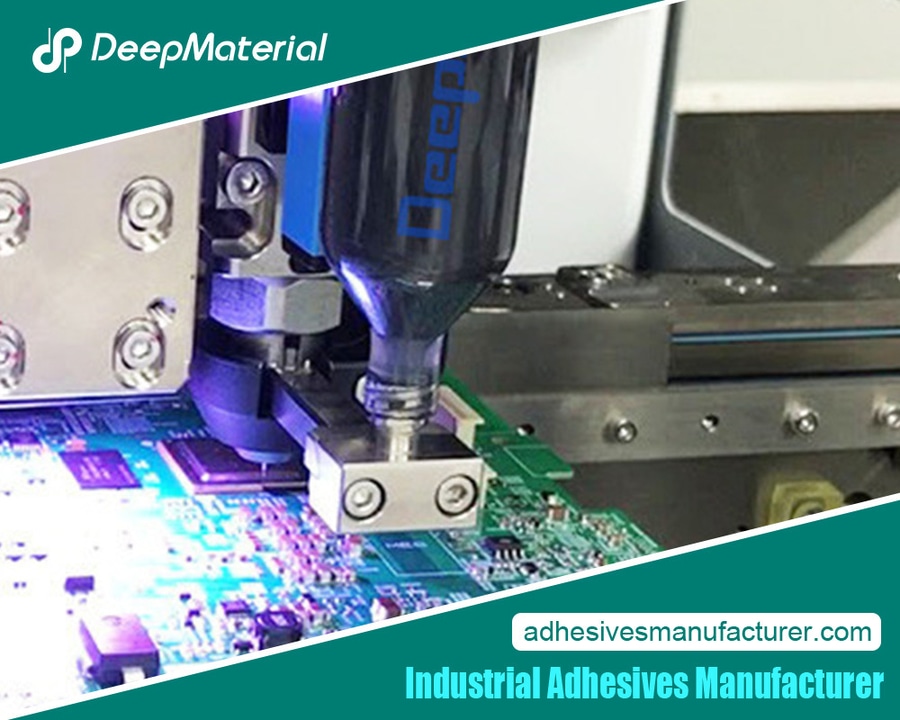

Growing Use of Automation

Automation in manufacturing processes is expected to drive the demand for epoxy adhesives compatible with automated dispensing systems. These adhesives will enable faster and more precise application, enhancing production efficiency.

Expansion in Emerging Markets

The epoxy adhesive market will likely see significant growth in emerging markets, driven by increased industrialization and infrastructure development. Manufacturers will expand their presence in these regions to tap into new opportunities.

Challenges Faced by Epoxy Adhesive Manufacturers

While the epoxy adhesive industry in Korea is thriving, manufacturers face several challenges that require strategic approaches to overcome:

Intense Competition

The global adhesive market is highly competitive, with numerous manufacturers vying for market share. Korean manufacturers must continually innovate and differentiate their products to stay ahead of the competition.

Regulatory Compliance

Adhesive manufacturers must adhere to stringent regulations regarding environmental impact and safety. Compliance with these regulations requires ongoing efforts to develop formulations that meet evolving standards.

Raw Material Costs

The cost of raw materials used in epoxy adhesive production can fluctuate, impacting manufacturing expenses. Manufacturers need to manage supply chains efficiently to mitigate the effects of price volatility.

Technological Advancements

Keeping pace with technological advancements is crucial for manufacturers to remain competitive. Investing in R&D and adopting new technologies are necessary to develop innovative adhesive solutions.

Customer Expectations

As industries evolve, customer expectations for adhesive performance and quality continue to rise. Manufacturers must prioritize customer satisfaction by delivering adhesives that meet or exceed these expectations.

Conclusion

Korean manufacturers of industrial epoxy adhesive glues have established themselves as leaders in the global market through their commitment to quality, innovation, and sustainability. Their advanced manufacturing processes focus on R&D, and their ability to provide customized solutions makes them a preferred choice for various industries.

For more about the best korean manufacturers of industrial epoxy adhesive glue, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.