#Product Trends

Alternative: Stud-Welding

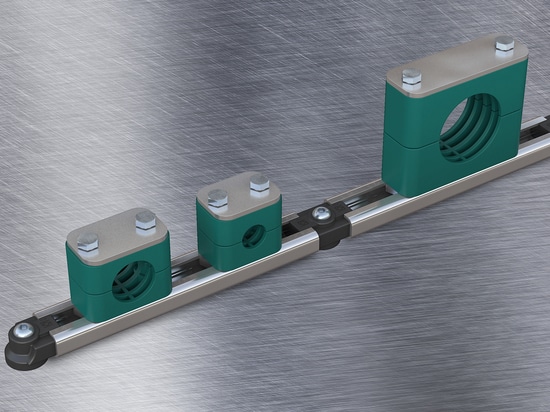

Increased productivity and flexibility for the installation of pipe, tube, hose and cable clamps

In many areas, stud welding is considered to be the most economic fastening method for components and is sometimes even the only technically feasible solution. Because the stud is joined with the substructure over the entire surface of the stud without any hollow areas, a high strength of the joint can be achieved.

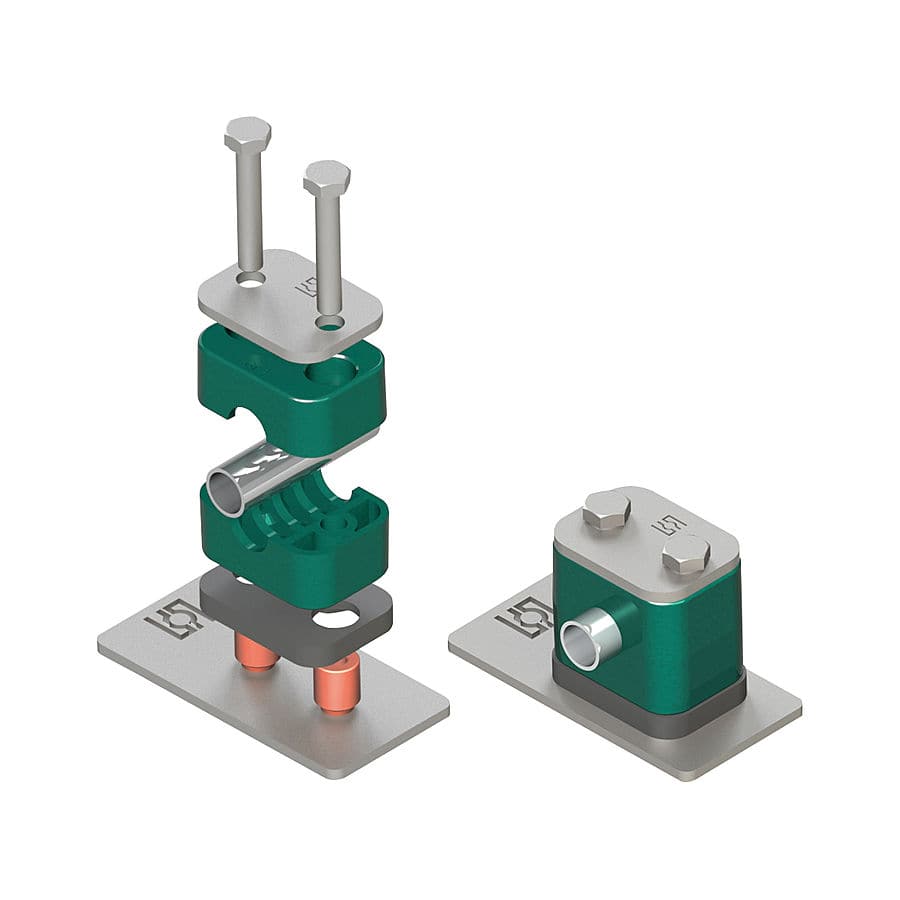

Stauff is now using this proven principle for the installation of pipe, tube, hose and cable clamps in the Standard Series (according to DIN 3015, part 1) with M6 mounting thread, where female threaded weld studs replace the regular weld plates; distance plates made from plastic provide the necessary spacing between the clamp bodies and the substructure. If required, the system can also be adopted for alternative fastening methods, e.g. for clamping belts, cable ties or corrugated cable protection hoses.

In addition to the individual components – weld studs, distance plates, clamp bodies and metal hardware required – the company also provides the correspondingly designed assembly tools such as the weld inverter and the weld gun with tripod, weld stud retainer and distance adaptor. The lightweight and compact weld inverter works without high-voltage current.

Thanks to increased productivity and flexibility for the installation of clamps, the system offers considerable savings potentials for users with significant processing volumes, especially when working in horizontal or overhead position. The amount of rework on welding locations can be significantly decreased, and material distortion is reduced to a minimum through low thermal stress.

The joint of the weld stud with the substructure impresses in particular with a high degree of strength and safety, which is at least at the same level as for regular weld plates.