#Product Trends

Time and cost savings in the assembly of tube, hose and cable clamps

Incredibly simple and quick: fastening Standard Series C-profile rails by stud welding

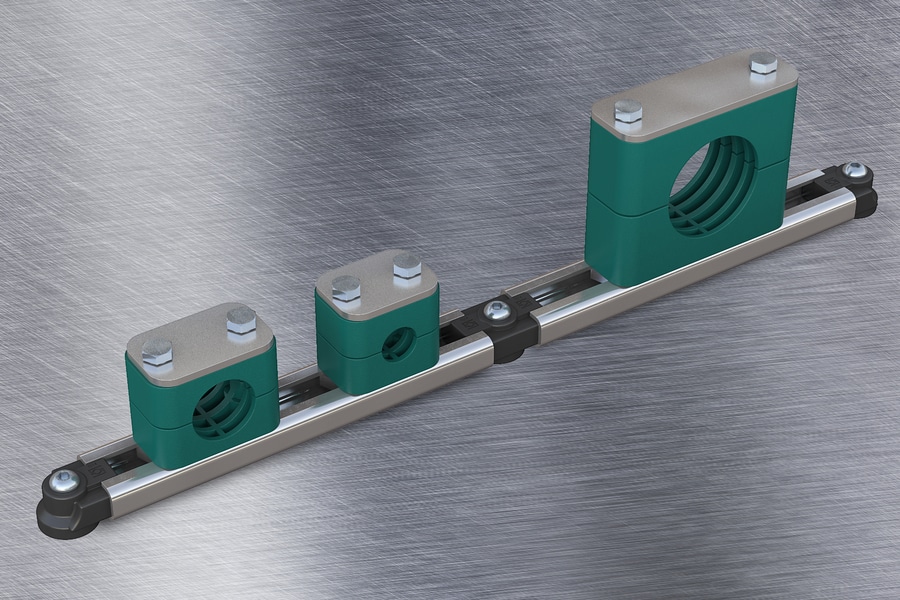

In response to customer requirements from different sectors, the fluid specialists at the Werdohl-based Stauff Group have extended their stud welding system with a further application for the secure and permanent fixing of tube, hose and cable clamps to substructures: Standard C-profile rails from the company’s own TS range can now be fixed to systems using fibreglass-reinforced polyamide adapters specially developed for this purpose, without them having to be point-welded or welded along their entire length, as was the case up to now in conventional processes. The plastic adapters per se are simply placed on the stud weld, which has previously been attached to the unit; both can be screwed together using M6 x 10 hexagonal socket screws or half-round screws.

Users therefore benefit from significant time savings, hence also cost savings, ease of use and improved flexibility in the assembly of profile rails. There is also much less need for time-consuming reworking of welding points. A further benefit lies in the fact that it is possible to ensure that the installed rails have a gap of approximately 1.5 millimetres from the substructure, eliminating the risk of through standing water.

Two versions of plastic adapters are immediately available for insertion into the open ends of the profile rails. Apart from fixing individual rails in place, this also enables several rails to be connected to each other.

Stud welding is used in many sectors as the most economical fastening method for components and is sometimes even the only technically feasible solution. As the entire surface of the copper-plated stud is jointed to the substructure, the connection is very strong. There is also minimal material distortion due to the short welding time, relatively low use of energy and isolated thermal stress, with the result that the system can also be used on comparatively thin-walled metal sheets and heat-resistant substrates.

In addition to supplying the individual components – weld studs, a wide range of different clamp bodies and fastening hardware, including for clamping belts, cable ties or corrugated cable protection hoses – Stauff also offers the correspondingly designed assembly tools, including a weld inverter, weld gun with positioning tube, weld stud retainer and distance adapters. No high-voltage connection is required to use the simple and compact tool.