#Industry News

How to Improve Power Conversion Efficiency of Charging Piles through PCBA Design

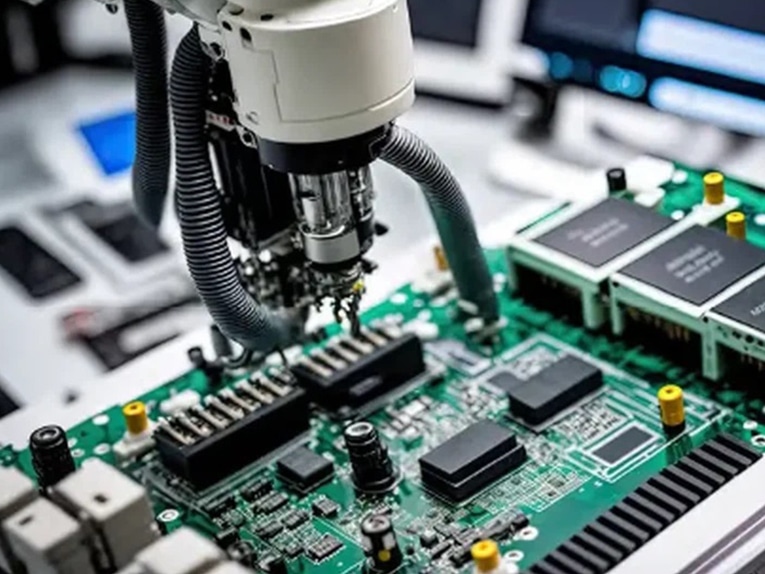

Power Conversion Efficiency of Charging Piles through PCBA Design

With the popularity of electric vehicles, charging piles serve as a critical infrastructure, and their power conversion efficiency directly affects charging speed. Therefore, improving the power conversion efficiency of charging piles is important. This article will explore how to enhance the power conversion efficiency of charging piles by optimizing PCBA design, along with TECOO's technological innovations and practical experience in this field.

1. Key Factors Influencing Power Conversion Efficiency of Charging Piles

Converter Design: Efficient DC-DC or AC-DC converters can achieve high-energy conversion and reduce energy loss.

PCB Layout and Wiring: Reasonable PCB layout and wiring design can minimize signal interference and energy loss, thereby improving overall conversion efficiency.

Component Selection: Using low-power, high-performance components is also crucial for enhancing efficiency.

2. Methods for Optimizing PCBA Design

Choose Efficient Power Components

In the PCBA design of charging piles, selecting high-efficiency components is the first step in improving power conversion efficiency. TECOO emphasizes performance when selecting components, using high-frequency switching MOSFETs and Schottky diodes to effectively reduce losses and ensure that each charging pile system has optimal energy conversion capabilities.

Optimize PCB Layout

Shortest Current Path: Minimize the connections between power components and other circuit elements to reduce parasitic inductance and resistance.

Good Thermal Design: Leave enough space for heat dissipation and thermal conduction for power components to ensure they can operate efficiently under high load while minimizing the impact of temperature on efficiency.

Rational Grounding Design: Optimize grounding paths to reduce interference, decrease energy loss, and enhance signal quality.

Use Multilayer PCBs

TECOO employs multilayer PCBs in design, effectively managing signal integrity and power management. This ensures that mutual interference between functional modules is minimized, significantly reducing electromagnetic interference and improving conversion efficiency.

Implement EMI Suppression Techniques

In the PCBA design of charging piles, adopting EMI suppression techniques is also important for improving efficiency. By using filters, common-mode inductors, and appropriate shielding designs, electromagnetic interference can be reduced, ensuring signal stability and enhancing overall power conversion efficiency.

Integrate Thermal Management Systems

Charging piles generate significant heat under high loads, and excessive temperatures can affect component performance and reduce efficiency. Integrating efficient cooling systems, such as heat sinks, thermal conductive materials, and fans in the PCBA design can effectively lower temperatures, ensuring that components operate in optimal conditions.

TECOO has an experienced R&D team capable of continuously optimizing the PCBA design of charging piles based on market demand. TECOO also maintains strong partnerships with several well-known component suppliers to ensure high performance and reliability of components. During production, TECOO implements strict quality management to ensure that each PCBA meets design standards, enhancing the overall performance of the product. TECOO is committed to providing efficient and reliable charging pile solutions for its customers.