#Industry News

Tederic Solution powers the world's largest luxury group — LVMH

According to public data, the market value of the global cosmetics industry has exceeded $560 billion. The success of a cosmetic product is not only based on its quality, but also on its appearance and packaging. High-quality packaging can not only enhance the visual appeal of the product, but also an important embodiment of brand value.

According to public data, the market value of the global cosmetics industry has exceeded $560 billion. The success of a cosmetic product is not only based on its quality, but also on its appearance and packaging. High-quality packaging can not only enhance the visual appeal of the product, but also an important embodiment of brand value.

With the continuous improvement of the market's requirements for cosmetics packaging in terms of materials, design innovation, production accuracy and environmental sustainability, this has become a key factor for brands to stand out in the fierce market competition and win the love of consumers.

For a manufacturer of plastic packaging for cosmetics founded in 1973, the texture and exquisite appearance of product details are the top priorities.

For more than 30 years, the company has been designing and manufacturing precision packaging for lipstick tubes, compacts, perfume bottles and other well-known brands such as LVMH (such as Guerlain, Dior and Givenchy) and other well-known brands such as CHANEL and YSL.

01 Technological Innovation: Precise Energy Saving Meets the Needs of Luxury Products

Walking into the customer's French factory, the production line is running in an orderly manner. Blush palettes, powder boxes, lipsticks...... Even the logo logo embellished on it, each beauty item is going through a series of complex injection molding processes, and finally transformed into a member of the luxury beauty collection.

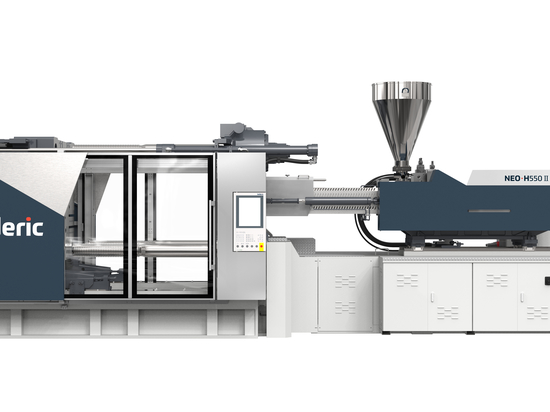

As a world leader in the high-end commoditization of beauty and luxury brands, precision is a key element that must not be compromised. To meet the dual challenges of precision and sustainability, customers choose Tederic as their partner. With the NEO· E Electric injection molding machines have recently been successfully delivered, and in the future, these will be successfully delivered by NEO· The beauty products manufactured by NEO· E Electric injection molding will be launched in LVMH's luxury stores.

The NEO· E Electric injection molding machine, which combines advanced electric technology and rich application experience accumulated in the packaging industry, comprehensively considers the customer's pursuit of efficient production and the demand for precision and durable products.

02 NEO· E Electric Injection Molding Machine: High Efficiency, Precision, Energy Saving

For an enterprise that attaches great importance to process stability and product consistency, NEO· E Electric injection molding machine is undoubtedly an ideal choice.

With its unique structure, it effectively suppresses production instability caused by rising oil temperatures. With high-precision lead screws, the two complement each other, significantly improve the stability of equipment operation and production accuracy, ensure consistent product quality, and bring stable manufacturing advantages to the enterprise.

More precise. The repeatability of the injection position can reach 0.01 mm. Precise control to achieve the appearance of more complex products, improve product texture and grade, and enhance brand premium for customers.

Energy-saving. The advanced energy recovery system is adopted, which can save energy by up to 15% compared with traditional motors, and meet the European injection molding machine Euromap9+ energy-saving standard, creating greater value for customers.

High efficiency. The motor has a faster dry cycle, and the standard linkage function significantly shortens the product molding cycle, increases production capacity, and improves human efficiency.

Low maintenance cost. There is no common interference in hydraulic pressure such as oil temperature leakage, and the equipment parameters are stable all year round; The number of parts is small, the troubleshooting is simple, and the maintenance cost is reduced.

Cleaner. Meet the high-quality production needs of high-end cosmetics.

03 Localization Services: Build A Foundation For Long-term Cooperation

With excellent localization services and overall solution delivery capabilities, Tederic has gradually become a high-profile press brand in the French and even the entire European injection molding machine market. In the process of providing services for local users for a long time, Tederic has accumulated rich experience, and has successively reached cooperation with leading companies in the industry such as Faurecia and Magna, and successfully created a series of one-stop intelligent injection molding solutions.

In the future, Tederic will continue to uphold the principle of "creating greater value for you" and is committed to working hand in hand with global customers and sustainable development. Strive to bring more convenient and efficient services and support to global users.