#Product Trends

Advanced Imaging Meets AI

Transforming Thermal Barrier Coating Analysis with the Apreo ChemiSEM

Material characterization is key to performance and safety in many industry sectors, yet conventional methods are often lacking. Thermo Scientific’s Apreo ChemiSEM system offers a complete and effective solution by integrating advanced imaging with AI-driven analysis, significantly improving the speed and accuracy of material evaluation.

Applied in a thin layer to the surface of a component, thermal barrier coatings (TBCs) can extend component lifespans by raising resistance to high temperatures, corrosion, and mechanical stress.1 For this reason, TBC’s have been widely adopted in the aerospace industry. However, characterizing and optimizing these materials remains a challenge due to their complex structures and performance requirements. The Apreo ChemiSEM system from Thermo Scientific provides a solution by using a correlative microscopy approach integrating various techniques with AI-assisted image analysis to streamline this characterization process.

Problem: The Constraints of Traditional Methods in Material Characterization

Industries using TBCs typically require the component to endure extreme conditions while supporting human life and expensive cargo. This is exemplified in aerospace applications where turbine blades and engine parts must operate in temperatures close to 1800 °C.

Traditional methods of material characterization, such as manual sample preparation and extended data analysis, can be slow and error prone. This leads to delays in material development and inefficiencies in quality control, ultimately impacting performance and safety.

TBCs typically consist of a ceramic top coat, a bond coat, and thermally grown oxides. The morphology, chemical composition, physical and mechanical properties of these layers can directly influence the effectiveness of the TBC. It is the intricacy of multi-layered materials such as these that present challenges to conventional imaging techniques with traditional sample preparation methods, such as cutting, grinding, and polishing, requiring considerable manual effort and time. Additionally, the manual processing and interpretation of scanning electron microscopy (SEM) images and compositional analysis over large areas is labor-intensive and can introduce user bias, further complicating the process.

Solution: The Integrated Approach of Thermo Scientific’s Apreo ChemiSEM

The Apreo ChemiSEM system is designed to overcome these challenges by combining high-resolution imaging, integrated chemical analysis, and advanced automation to streamline the material characterization process. Outlined below of the necessary steps to overcome these key challenges:

1. Efficient Sample Preparation

To overcome time-consuming and labor-intensive sample preparation methods, the Apreo ChemiSEM system is compatible with the CleanMill Broad Ion Beam System to significantly reduce sample preparation time from up to 13 hours to just 90 minutes. This ensures that even complex materials like TBCs can be prepared efficiently without compromising data quality.

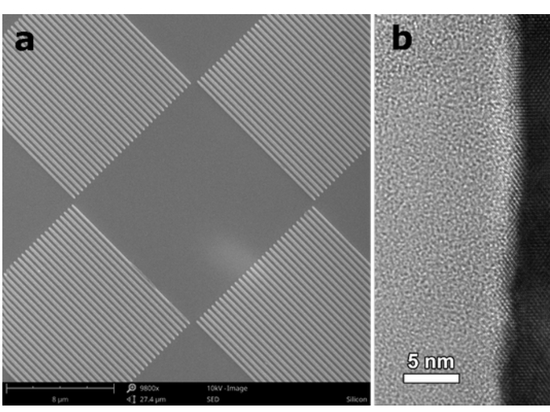

2. High-Resolution Imaging for Large and Complex Samples

The Trinity Detection System of the Apreo ChemiSEM provides high-resolution imaging even for complex samples by simultaneously gathering surface, topographical, and compositional information offering a comprehensive set of information all at once. A workflow like the one described, optimized for maximum automation to ensure the most reliable results, is especially valuable in industrial settings. In these environments, the ability to quickly and accurately analyze large samples can lead to higher-performing products with improved longevity.

3. Comprehensive Chemical and Structural Analysis

A key feature of the Apreo ChemiSEM is its ChemiPhase Technology, which automatically maps the distribution and quantifies different phases within a material. In aerospace applications, this technique enables detailed analysis of TBC bond coats and top coats, identifying phase transformations caused by high-temperature exposure. The system’s TruePix Electron Backscatter Diffraction (EBSD) Detector and EBSD software further enhance the material characterization by providing crystallographic information alongside chemical composition, allowing for deeper insights into material properties like grain structure, which are crucial for high-stress applications.

4. Correlative Microscopy and AI-Assisted Image Analysis

The Apreo ChemiSEM integrates multiple imaging modalities to provide a comprehensive view of material microstructures. SEM is used in conjunction with Energy Dispersive X-ray Spectroscopy (EDS) to identify the different materials present within the various TBC’s layers, while AI-assisted image analysis automates phase detection over the entire surface of the material. This allows for the simultaneous visualization of morphology and chemical composition over a large area, reducing manual input and speeding up time-to-results. By automating image analysis through machine learning, the system can identify and segment phases with an accuracy of over 95 % for phase segmentation metrics. This AI-driven approach guarantees faster, more accurate characterization of complex materials.

Industry Impacts: Implications for Aerospace, Automotive, and Battery Manufacturing

The Apreo ChemiSEM system’s capabilities are especially beneficial in high-performance industries like aerospace, automotive, and battery manufacturing, as highlighted below:

> Aerospace: as explained above, TBCs used in aircraft engines can be characterized for elemental diffusion, phase transformation, and structural integrity after prolonged service at extreme temperatures. The rapid analysis provided by the Apreo ChemiSEM helps ensure component reliability and reduce maintenance costs. Furthermore, automated and comprehensive materials characterization enables thorough inspection of the diverse materials used in aerospace, offering deeper insights into this constantly evolving industry.

> Automotive: The Apreo ChemiSEM system enables the detailed examination and optimization of coatings and materials used in the automotive industry. Improved coatings enhance vehicle durability by providing better protection against corrosion, UV damage, and wear, while also improving fuel efficiency through low-friction or aerodynamic properties. Additionally, long lasting coatings, and superior finishes offer a better aesthetic appeal with lower maintenance costs..

> Battery Manufacturing: Lithium-ion battery components require precise control over material composition and microstructure. The Apreo ChemiSEM could offer imaging and chemical analysis of complex multi-layer solid-state electrolytes for lithium batteries, allowing for improved understanding and optimization of electrolyte interfaces. This could raise battery performance, boost energy density, and increase safety in solid-state lithium batteries, making the system highly valuable for advancing next-generation battery technologies.

Conclusion: Greater Industrial Performance with the Apreo ChemiSEM

Thermo Scientific’s Apreo ChemiSEM system provides an efficient, automated solution for material characterization in industries where high performance and reliability are essential. By integrating correlative microscopy with AI-assisted analysis, the system significantly reduces the time and complexity involved in analyzing multi-layered materials like TBCs, automotive coatings, and battery components. For aerospace, automotive, and battery manufacturers, the Apreo ChemiSEM is a powerful tool that promises to accelerate product development, tighten quality control, and ensure the long-term durability of critical components. Its ability to integrate with other devices, allowing for improved sample preparation and automated imaging, and phase analysis, makes it a vital asset for any industrial lab facing the challenges of modern material characterization.

References and Further Reading

1. NASA. (2010). [Online] Coatings Extend Life of Engines and Infrastructure. Available at: https://spinoff.nasa.gov/Spinoff2010/t_7.html (Accessed on 18 September 2024).

2. Thermo Scientific. (2024). [RESOURCE PROVIDED IN BRIEF] App Note, Datasheet, Case Study, White Paper, Technical Note.

3. ThermoFisher Scientific. [Datasheet] Apreo ChemiSEM System. Available at: https://assets.thermofisher.com/TFS-Assets/MSD/Datasheets/apreo-chemisem-system-ds0508-en.pdf

4. Hu, Y, et al. (2023). Multi-layered electrolytes for solid-state lithium batteries. Next Energy. doi.org/10.1016/j.nxener.2023.100042

5. Clerici, D. (2024). Diffusion-induced stress amplification in phase-transition materials for electrodes of lithium-ion batteries. International Journal of Mechanical Sciences. doi.org/10.1016/j.ijmecsci.2024.109541

6. Bogdan, M., et al. (2024). A Comprehensive Understanding of Thermal Barrier Coatings (TBCs): Applications, Materials, Coating Design and Failure Mechanisms. Metals. doi.org/10.3390/met14050575