#Product Trends

Gap-Filler dispensing

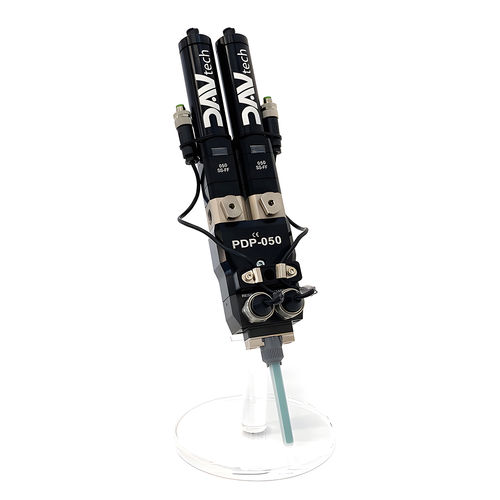

Using DAV Tech PDP pumps is possible to have an accurate, clean, reliable and consistent dispensing process.

A topic that has received a notable success, following a progressive electrification of actuators and drive motors, is the thermal management and it is still one of the most discussed topics by designers.

The dispensing of thermo-conductive pastes has soon became a forced choice for several reasons: to automate the assembly process; to dissipate and to keep under control the temperature of electronic components; and to compensate for any games between the parties.

How does the dispensing happen?

These pastes, called Gap Filler in jargon, can be single-component or bicomponent and are usually loaded to transmit the heat efficiently.

Through the DAV Tech volumetric pumps PCP or PDP, the Gap Filler dispensing process guarantees an accurate, adjustable, and especially repeatable deposition. The rotors are available in Carbide or even in Ceramics (instead of the classic stainless inox) to counteract the abrasive effect.

Which are the application cases?

The thermo-conductive pastes are used for different types of dispense but the most common application are the incorporation of sensors and temperature probes, the heat dissipation on electronic circuit board and the temperature dissipation on e-mobility battery packs.