#Industry News

The Benefits of Heat Preservation

A Natural Approach to Food Storage

In the realm of industrial food preservation, the quest for efficient and effective methods to extend the shelf life of products while maintaining their quality and safety is paramount. Among the array of preservation techniques available, heat preservation stands out as a cornerstone of modern food processing. Unlike home-based approaches, industrial heat preservation involves sophisticated technologies and processes tailored to meet the rigorous demands of large-scale food production.

1. Additive-Free Preservation:

Industrial heat preservation methods prioritize the use of heat as the primary means of preserving food, eliminating the need for artificial additives such as preservatives, colorants, and flavor enhancers. By relying on controlled heating processes, manufacturers can effectively destroy harmful microorganisms and enzymes that lead to spoilage, ensuring that products remain fresh and safe for consumption without compromising their natural integrity. This additive-free approach aligns with consumer preferences for clean-label products and addresses concerns regarding the potential health risks associated with synthetic additives.

2. Extended Shelf Life:

Industrial heat preservation techniques, such as pasteurization and sterilization, play a crucial role in extending the shelf life of a wide range of food products. By subjecting foods to specific heat treatments at precise temperatures and durations, manufacturers can deactivate spoilage-causing microorganisms while preserving the product’s quality and nutritional value. This extended shelf life not only reduces food waste but also enhances product availability, distribution efficiency, and overall sustainability within the food industry.

3. Retained Nutritional Value:

One of the key advantages of industrial heat preservation is its ability to retain the nutritional content of food products throughout the processing and storage stages. By carefully controlling the heating parameters, manufacturers can minimize the degradation of essential vitamins, minerals, and other beneficial compounds, ensuring that the majority of these nutrients remain present in the food product after processing. This focus on preserving nutritional value aligns with consumer preferences for healthy and nutritious food options, providing reassurance that processed foods maintain their inherent health benefits.

4. Enhanced Flavor and Texture:

Industrial heat preservation methods are designed to preserve not only the nutritional content but also the flavor, texture, and overall sensory characteristics of food products. By utilizing precise heat treatments tailored to each product type, manufacturers can maintain the natural taste, aroma, and mouthfeel of foods, delivering a consistent and enjoyable eating experience for consumers. This attention to flavor and texture preservation sets industrial heat preservation apart as a method that prioritizes both food safety and sensory quality.

5. Cost-Effectiveness and Convenience:

Industrial heat preservation offers cost-effective solutions for food manufacturers by streamlining production processes, reducing the need for additional preservatives or additives, and enabling bulk processing and storage of products. The efficiency of heat preservation methods allows for increased production capacity, optimized supply chain management, and reduced operational costs, ultimately contributing to improved profitability and competitiveness in the food industry. Additionally, the convenience of industrial heat preservation enables manufacturers to meet consumer demand for safe, high-quality products while maintaining operational efficiency and scalability.

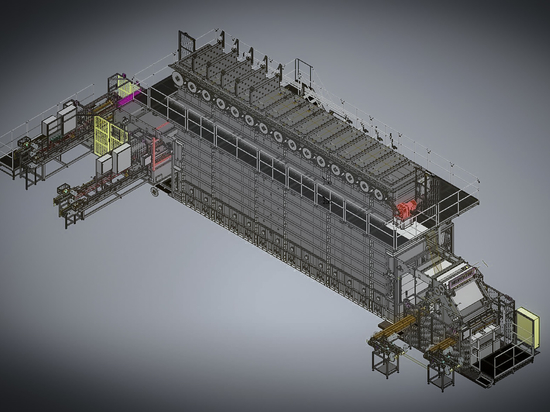

At InnovaSter-Trade Ltd, we understand the importance of heat treatment in preserving the quality and safety of food products. That’s why we offer a range of innovative machines designed to meet the specific needs of food producers. Our product portfolio includes both batch and continuous sterilization systems, ensuring that our clients can choose the solution that best suits their production requirements. For smaller-scale operations, our batch retort autoclaves provide a reliable and efficient way to heat treat products. For high-volume production, our HIDROSTER brand continuous sterilizers offer uninterrupted operation and high throughput. With over 30 years of experience in the industry, we are committed to providing dependable, energy-saving solutions that help our clients advance their heat treatment capabilities and meet growing global demand.