#Industry News

Batch vs Continuous Sterilization

Choosing the Right Sterilization Process for Your Food Plant

When it comes to sterilizing food products, food manufacturers have two main options: batch processing or continuous processing. Each method has its own advantages and is suited for different production volumes and requirements. Let’s explore the key differences between batch and continuous sterilization to help you determine which approach is best for your food plant.

Batch Retort Autoclave: Flexibility for Smaller Quantities

The batch retort autoclave is a popular choice for food plants producing smaller quantities. In this method, products are placed in baskets or cages and fed into the autoclave in a cage. After the sterilization process is complete, the products exit the unit. While batch processing doesn’t allow for continuous operation, it offers flexibility in terms of product variety and smaller production runs. Autoclaves are ideal for plants that need to sterilize a diverse range of products or have fluctuating demand.

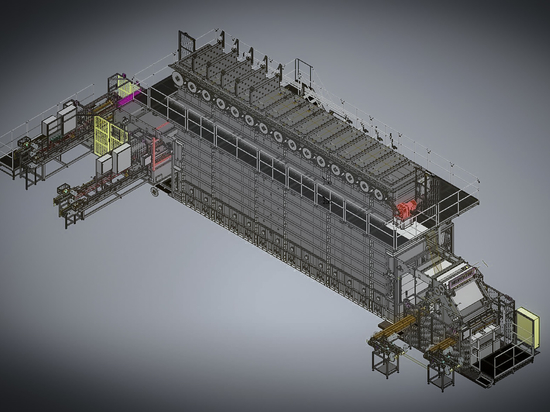

HIDROSTER: Continuous Sterilization for High-Volume Production

For food plants with high-volume production needs, the HIDROSTER brand continuous sterilizer is a game-changer. This automatic system allows for uninterrupted operation, maximizing efficiency and output.The advantages of continuous sterilization are numerous:

Short-term heat treatment at high temperatures helps preserve the natural taste, nutrients, and texture of the products.

Consistent heat treatment for each can ensures uniform product quality.

Higher production volumes in the same amount of time, making it more economical for large-scale operations.

By continuously heating and cooling each can for the same duration, the HIDROSTER ensures that every product receives the exact same sterilization treatment, resulting in a consistently high-quality end product.

Consistent Heat Treatment in Continuous Sterilizers

In batch processing using autoclaves, products are loaded into baskets or cages and placed inside the equipment in large numbers. However, this method can lead to inconsistent heat treatment.

Products located on the outer edges of the baskets or cages are exposed to heat earlier and for a longer duration compared to those in the center. This uneven heat exposure results in variations in the sterilization process, as the outer products receive more heat treatment than the inner ones.

Furthermore, the loading and unloading of products in batches can cause fluctuations in heat exposure, leading to further inconsistencies.

The intermittent nature of batch processing makes it challenging to maintain uniform heat treatment throughout the entire batch.

In contrast, continuous sterilizers are designed to provide consistent heat treatment to all products passing through the system. By maintaining a continuous flow and uniform heating and cooling, each product receives the same level of heat treatment, ensuring reliable and uniform sterilization. Continuous sterilizers also allow for precise control of processing parameters, such as temperature, pressure, and flow rate, further contributing to the consistency of the heat treatment process. This control ensures that the sterilization conditions remain stable throughout the operation, leading to uniform product quality.

Choosing the Right Sterilization Process for Your Needs

When deciding between batch and continuous sterilization, consider your production volumes, product variety, and budget. Autoclaves are ideal for smaller plants or those with fluctuating demand, while the HIDROSTER is the preferred choice for high-volume production facilities.Ultimately, the key to successful sterilization lies in choosing a method that not only ensures food safety but also preserves the quality and integrity of your products. By carefully evaluating your specific needs and production requirements, you can select the sterilization process that will help your food plant thrive in today’s competitive market.