#Product Trends

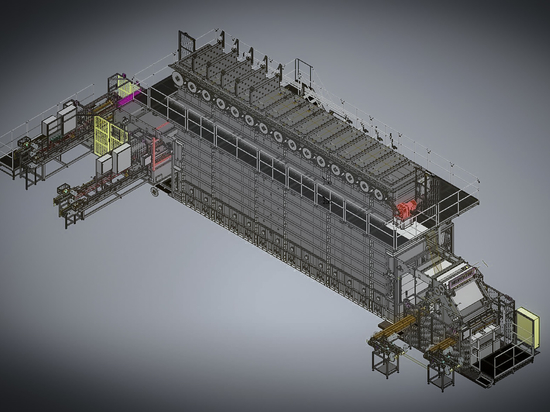

HIDROSTER

The Split Hydrostatic Technology

The HIDROSTER machine operates on the hydrostatic principle, sterilizing products at temperatures above 100°C under constant external overpressure. It achieves the required hydrostatic pressure through a series connection of low water columns.

The equipment features two separate hydrostatic systems on each side of the highest pressure steam chamber, one for heating and one for cooling, maintained by compressed air to establish hydrostatic balance. Each water bath and sterilization chamber has an independent temperature controller, ensuring precise control. The equipment can independently heat each individual water bath to the most favorable temperature for the technology, regardless of each other and the pressure, using direct steam injection while in a state of hydrostatic equilibrium.

Each water bath and sterilisation chamber is equipped with an independent temperature controller. The equipment includes an instrument cabinet containing all necessary measuring, control, recording and indicating equipment.

The machine utilizes a vertical serpentine track with stainless steel chains for the hydrostatic systems and steam room, allowing for adjustable speed and automatic loading and unloading of cans. Its design enables processing multiple sizes or types of products simultaneously.

For a visual demonstration of the machine in operation, you can view it on YouTube at https://www.youtube.com/watch?v=AN_5yZUQ2Po