#Industry News

How Ceramic Blasting Beads Clean Aluminum Alloy Parts

A Comprehensive Guide to Using Ceramic Blasting Beads for Aluminum Alloy Surface Finishing

Ceramic blasting beads are an effective and versatile abrasive used for cleaning and surface preparation of aluminum alloy parts. This guide will provide a detailed overview of how ceramic blasting beads work, their benefits, and the best practices for using them to achieve optimal results.

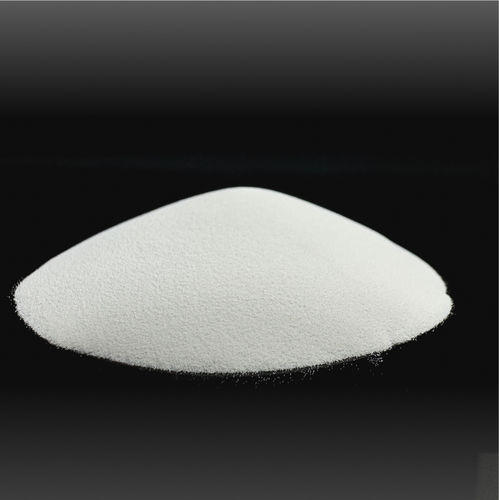

What are Ceramic Blasting Beads?

Ceramic blasting beads are a type of synthetic abrasive made from high-quality ceramic materials. They are known for their hardness, durability, and low dust generation, making them suitable for a wide range of applications, including blasting, grinding, and polishing.

Benefits of Using Ceramic Blasting Beads

1. Hardness: Ceramic beads are highly hard, making them effective for removing tough coatings and contaminants.

2. Reusability: They are highly durable and can be reused multiple times in blast cabinets, reducing overall abrasive consumption and waste.

3. Versatility: Ceramic beads can be used on various substrates, including aluminum, steel, and other metals.

4. Consistency: They provide consistent results in terms of surface finish and profile, helping to achieve desired surface preparation standards.

5. Cost-Effectiveness: While ceramic beads may be more expensive than some other abrasives, their durability and recyclability can lead to cost savings over time.

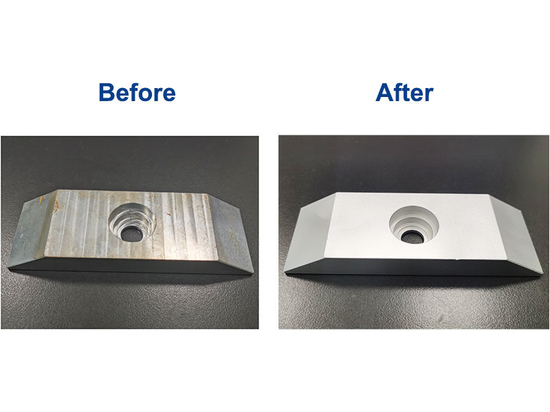

How Ceramic Blasting Beads Clean Aluminum Alloy Parts

1. Surface Preparation: Ceramic blasting beads effectively remove rust, paint, and other coatings from surfaces, preparing them for painting or other finishes. Their hardness allows them to etch and profile surfaces, enhancing the adhesion of coatings.

2. Choosing the Right Grit Size: Coarser grits are ideal for heavy-duty applications, while finer grits are best for delicate tasks. Adjust the blasting pressure according to the task at hand. Higher pressure increases the rate of material removal but can also cause more wear on the blasting equipment.

3. Proper Handling and Storage: Store ceramic blasting beads in a dry place to prevent clumping. Seal unused media to prevent contamination and handle with care to avoid creating dust or unnecessary breakdown.

4. Safety Measures: Wear protective gear such as safety goggles, gloves, and a dust mask. Ensure adequate ventilation in your workspace to prevent the buildup of dust. Always adhere to the guidelines provided by your blasting equipment manufacturer.

5. Surface Precautions: Test on a small area before blasting an entire surface to ensure it won’t damage the material. Protect adjacent areas to prevent accidental damage. Consider the material hardness and adjust the pressure or grit size accordingly.

Industry Applications

Ceramic blasting beads are widely used in various industries, including:

1. Metalworking: For cleaning, deburring, and surface preparation of metal parts.

2. Automotive: For removing paint and rust from car parts.

3. Aerospace: For surface preparation of aircraft components.

4. Electronics: For micro-blasting electronic components.

5. Restoration: For cleaning and restoring historic buildings and monuments.

Conclusion

Effectively using ceramic blasting beads involves careful handling, adhering to safety measures, and considering their environmental impact. By following these guidelines, you can ensure a safe and efficient blasting process that delivers high-quality surface finishes on aluminum alloy parts.

By choosing the right ceramic blasting beads and following best practices, you can achieve the desired finish on your aluminum alloy parts, ensuring they are ready for further processing or final use.