#Industry News

How Zirconia Beads Enhance the Stability and Longevity of Implants

Unlocking Enhanced Stability and Longevity for Medical Implants

In modern medical technology, implants ranging from dental implants to orthopedic prosthetics are widely used to restore function and improve patients' quality of life. However, ensuring the stability and longevity of these implants within the body remains a critical challenge. Zirconia blasting beads, a high-performance surface treatment material, have emerged as a solution to enhance implant performance.

1. Characteristics of Zirconia Blasting Beads

High Hardness and Wear Resistance

Zirconia (ZrO₂) has a Mohs hardness of 8-9, second only to diamond. This high hardness allows zirconia beads to effectively remove oxides and contaminants, improving surface roughness and enhancing bone tissue bonding.

The durability of zirconia beads ensures consistent performance over time.

Chemical Stability

Zirconia resists chemical corrosion, forming a protective layer on the implant surface to prevent degradation and maintain mechanical properties.

Biocompatibility

Zirconia materials do not induce rejection reactions and bond well with biological tissues. Sandblasting enhances surface roughness, improving implant stability and longevity.

2. Applications in Implants

Customized Design

Zirconia blasting beads can be tailored for personalized implants by adjusting particle size and blasting intensity. This ensures optimal bonding and adaptability.

Micromachining Technology

For miniaturized implants, zirconia beads provide precise surface treatment, meeting stringent requirements for micro-scale applications.

Long-Term Clinical Follow-Up

Long-term studies show that zirconia blasting beads significantly reduce implant failure rates and improve overall performance.

3. Impact on Implant Performance

Increased Mechanical Strength

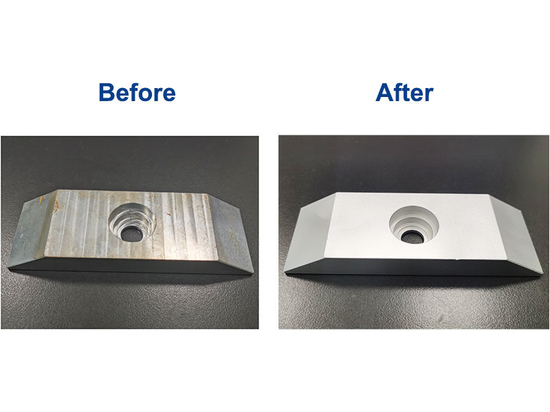

Sandblasting removes surface defects, enhancing mechanical strength and reducing wear and fatigue.

Enhanced Bone Integration

Improved surface roughness provides more mechanical lock points, enhancing implant stability and reducing displacement risks.

Corrosion Prevention

The protective layer formed by zirconia beads prevents corrosion in the body's acidic and alkaline environments.

4. Practical Application Cases

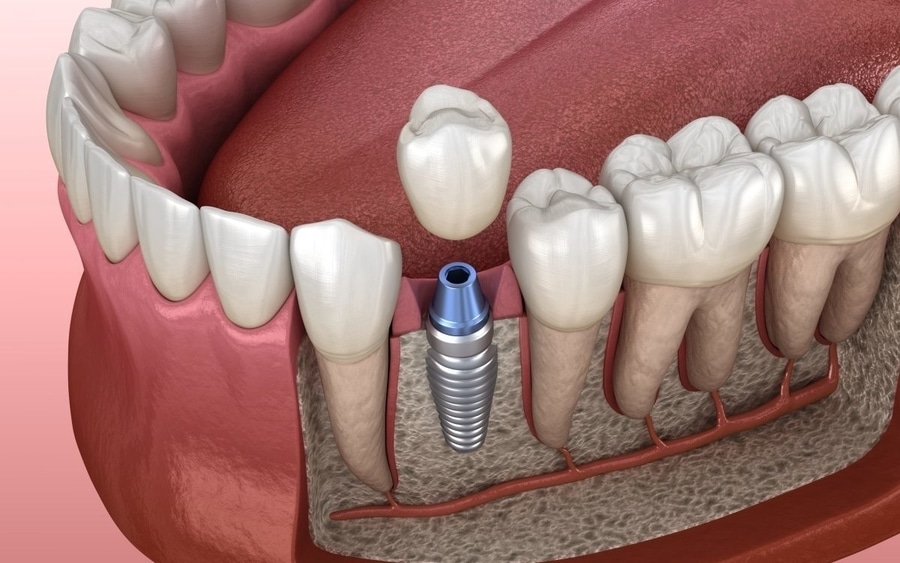

Dental Implants

Straumann: Sandblasted dental implants showed a 95% bone integration rate within 6 months and a 2% failure rate over 5 years.

Nobel Biocare: Sandblasted implants demonstrated a 98% success rate and a 20% increase in bone integration strength.

Orthopedic Implants

Aesculap: Sandblasted orthopedic implants showed no significant wear after 5 million load cycles and a 90% recovery rate in clinical trials.

DePuy Synthes: Sandblasted hip replacements had a 90% stability rate over 10 years, extending lifespan by 20%.

5. Future Directions

Technological Innovation

Advances in sandblasting techniques and equipment will improve processing efficiency.

Eco-friendly Materials

Research will focus on developing more sustainable sandblasting materials.

Integrated Applications

Combining zirconia blasting beads with 3D printing and nanotechnology will further enhance implant performance.

Personalized Medicine

Sandblasting technology will adapt to personalized implant designs to meet individual patient needs.

6. Conclusion

Zirconia blasting beads offer significant advantages in improving implant stability and longevity. Their high hardness, chemical stability, and biocompatibility make them a valuable tool in modern medical technology. As research and development continue, zirconia blasting beads will play an increasingly important role in advancing the performance and application scope of medical implants.