#Product Trends

The Application of Ceramic Bead Blasting Media in Metal Processing

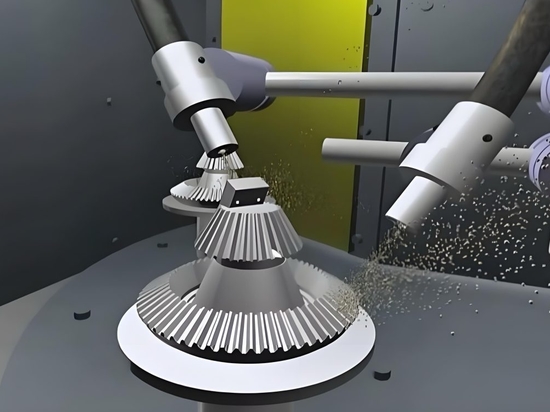

Revolutionizing Metal Surfaces: A Glimpse into the Microscopic Powerhouses Transforming Metal Processing

In the realm of metal processing, surface treatment is a crucial step in enhancing the performance and appearance of parts. Ceramic bead blasting media, with its exceptional physical properties and wide range of applications, has become an indispensable "secret weapon" in modern metal processing. This article delves into the applications of ceramic bead blasting media in metal processing and reveals how it can bring a qualitative leap to metal surfaces.

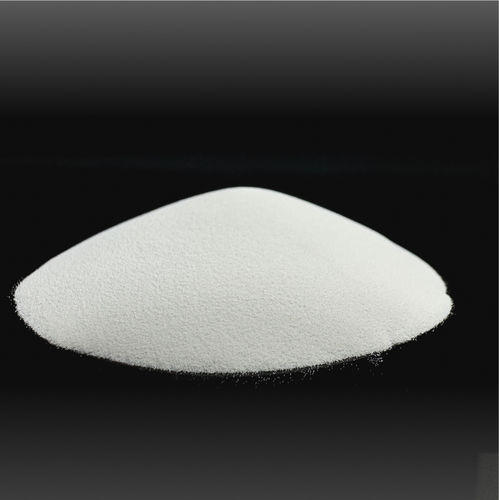

1. Unique Advantages of Ceramic Bead Blasting Media

Ceramic bead blasting media, especially those made from zirconium oxide, have become the ideal choice for metal processing due to their high hardness (over 60HRC), low dust generation, and recyclability. Compared to traditional blasting materials, ceramic beads offer the following significant advantages:

High Hardness and Low Wear: With a hardness of up to 60HRC, ceramic beads last 15-20 times longer than glass beads.

Eco-Friendly and Low Pollution: Ceramic beads are less prone to breakage during blasting, producing minimal dust and ensuring a safer working environment for operators.

High Surface Quality: The metal surface after blasting is smooth and uniform, significantly enhancing the aesthetic and mechanical properties of the parts.

2. Specific Applications in Metal Processing

Ceramic bead blasting media have a wide range of applications in metal processing, covering almost every aspect from surface cleaning to strengthening treatments.

2.1 Surface Cleaning and Decontamination

Removing Oxidation and Rust: Ceramic bead blasting efficiently removes oxide layers, rust, and oil from metal surfaces, restoring the metal's original color.

Cleaning Castings and Forgings: Ceramic beads remove burrs, flash, and sand particles from castings and forgings, improving surface finish.

2.2 Enhancing Surface Roughness

Increasing Coating Adhesion: Blasting creates a uniform roughness on the metal surface, significantly enhancing the adhesion of coatings or paint.

Improving Lubrication Performance: The micro-pits on the blasted surface can store lubricating oil, reducing friction and extending the life of parts.

2.3 Shot Peening

Enhancing Fatigue Resistance: Ceramic bead shot peening forms a cold-worked hardened layer on the metal surface, significantly improving the fatigue strength of parts.

Eliminating Residual Stresses: Shot peening effectively removes residual stresses generated during part processing, enhancing the overall performance of the parts.

2.4 Aesthetics and Decoration

Matte and Sandblasted Effects: Ceramic bead blasting achieves a matte or sandblasted finish on metal surfaces, meeting the aesthetic requirements of high-end products.

Pattern and Text Processing: Engraving patterns or text on mold surfaces enhances the added value of products.

3. Why Choose Ceramic Bead Blasting Media?

Among various blasting materials, ceramic bead blasting media stand out due to their efficiency, environmental friendliness, and durability. Compared to traditional glass beads or steel grit, ceramic beads not only have a longer service life but also significantly reduce dust pollution, enhancing the safety of the working environment. Additionally, the high hardness and uniform particle size distribution of ceramic beads make them excel in surface treatment, whether for cleaning, strengthening, or decoration.

4. Future Outlook

With the continuous development of metal processing technology, the application prospects of ceramic bead blasting media are becoming even broader. In the future, ceramic bead blasting media are expected to play an important role in more precise processing fields, such as aerospace, medical devices, and high-end electronic equipment manufacturing. At the same time, with increasing environmental requirements, the low-dust and recyclable characteristics of ceramic beads will make them the preferred material in the metal processing industry.

Conclusion

Ceramic bead blasting media, with their exceptional performance and wide range of applications, are becoming the new standard in metal processing. Jiangsu Henglihong Technology Co., Ltd., as a leading company in the industry, is committed to providing high-quality ceramic bead blasting media and customized solutions to help drive the high-quality development of the metal processing industry.

#CeramicBeadBlasting #MetalProcessing #SurfaceTreatment #EcoFriendlyTech #PrecisionEngineering