#Industry News

How do ceramic beads replace corundum to achieve efficient surface cleaning?

The Advantages of Ceramic Beads Over Corundum in Surface Cleaning

Surface cleaning is a crucial step in modern industrial production, as it enhances product quality and extends the lifespan of equipment. Traditionally, corundum (alumina) has been widely used in sandblasting cleaning processes. However, due to its high hardness, brittleness, and tendency to produce a significant amount of dust, corundum poses potential risks to equipment and the health of operators. In recent years, with the advancement of technology, ceramic beads have gradually gained attention as a new type of sandblasting medium. They have successfully replaced corundum in many fields, achieving more efficient and environmentally friendly surface cleaning.

1. Characteristics and Advantages of Ceramic Beads

Ceramic beads are typically made from high-hardness ceramic materials, such as zirconia and silica, and offer the following significant advantages:

High Hardness and Wear Resistance: Ceramic beads have a hardness comparable to corundum but with higher toughness, allowing them to remain stable through multiple sandblasting cycles.

Low Dust Generation: Compared to corundum, ceramic beads produce minimal dust during sandblasting, reducing wear on equipment and pollution in the operating environment.

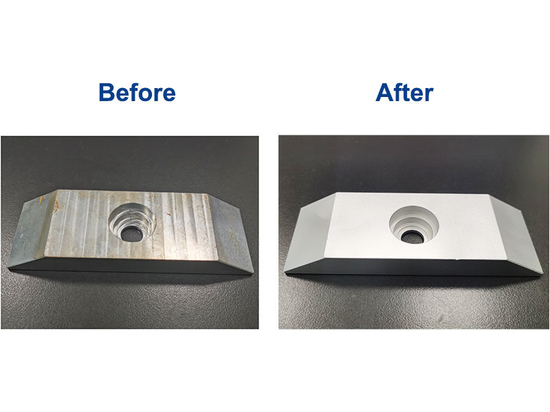

Superior Surface Cleaning Effect: The spherical structure of ceramic beads enables them to uniformly impact the surface of workpieces, removing oxides, rust, coatings, and other impurities without damaging the substrate.

Environmental and Economic Benefits: Ceramic beads are reusable, have a long service life, and reduce material consumption and waste emissions.

2. Applications of Ceramic Beads in Surface Cleaning

Ceramic beads are widely used for surface cleaning and treatment of various materials, including metals, glass, and plastics. For example:

Metal Surface Cleaning: Ceramic beads can remove oxides, rust, and coatings from metal surfaces while achieving a smooth satin finish.

Precision Cleaning: For workpieces that require high-precision surface treatment, such as aerospace components and medical implants, ceramic beads can achieve extremely low surface roughness, meeting stringent industry standards.

Cleaning of Complex-Shaped Workpieces: The spherical structure of ceramic beads allows them to effectively clean complex shapes and intricate geometries without causing damage.

3. Technical Advantages of Replacing Corundum with Ceramic Beads

The replacement of corundum with ceramic beads in surface cleaning offers several key benefits:

Higher Cleaning Efficiency: The high hardness and low dust generation of ceramic beads make them more efficient in removing impurities during sandblasting, while also reducing equipment maintenance time.

Better Surface Quality: Ceramic beads can achieve a more uniform and smoother surface finish, reducing scratches and damage.

Environmental and Safety Benefits: The low dust generation and reusability of ceramic beads give them an edge over corundum in terms of environmental protection and operational safety.

4. Solutions from Jiangsu Henglihong Technology Co., Ltd.

Jiangsu Henglihong Technology Co., Ltd. is committed to providing advanced surface cleaning technologies and solutions. The company uses high-quality ceramic beads combined with state-of-the-art sandblasting equipment and processes to offer efficient and environmentally friendly surface cleaning services for industries such as metal processing, aerospace, and automotive manufacturing. By optimizing sandblasting parameters (such as bead size, sandblasting pressure, and angle), we can achieve the best cleaning results tailored to the specific needs of different workpieces.

5. Market Competition and Differentiation

In the ceramic bead market, Jiangsu Henglihong Technology Co., Ltd. has established a differentiated competitive advantage through its advanced technology, high-quality products, and customized solutions. Compared to international brands such as Hira Ceramics and Oriental Zirconia, our company places greater emphasis on localized services and customer-specific needs. Additionally, we continuously invest in R&D to optimize product performance and meet higher industrial application standards.

6. Conclusion

As a new type of sandblasting medium, ceramic beads are gradually replacing traditional corundum due to their high hardness, low dust generation, environmental friendliness, and efficiency. Jiangsu Henglihong Technology Co., Ltd., with its advanced technology and extensive experience, can provide customized surface cleaning solutions to help various industries achieve more efficient and environmentally friendly production.

Jiangsu Henglihong Technology Co., Ltd.

Committed to providing efficient and environmentally friendly surface cleaning solutions, driving industrial production towards greener and more sustainable development.