#Industry News

How Does Ceramic Bead Blasting Media Revolutionize Surface Treatment in Precision Manufacturing?

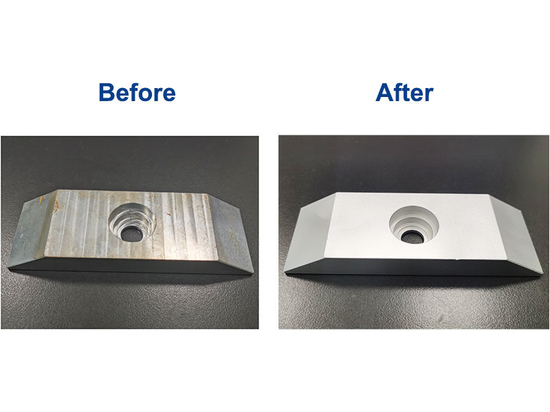

In the industrial field of surface treatment, the innovation of blasting technology is closely linked to breakthroughs in materials science.

I. Technical Principles: The "Chinese Chip" for Micron-Level Precision Processing

Henglihong's ceramic bead blasting media is based on self-developed high-purity zirconium oxide (ZrO₂) composite ceramics, formed into spherical particles with a particle size range of 50-3000 microns through patented sintering processes. The technical originality is reflected in the following aspects:

1. Ultra-Precision Spherical Control: Utilizing plasma fluidized bed forming technology, the roundness deviation of the ceramic beads is ≤0.3% (compared to the international standard of ≤1.2%), with a kinetic energy transfer efficiency increased by 40%. This significantly reduces the risk of micro-cracks on the workpiece surface.

2. Multi-Layer Structural Design: The outer layer consists of nanocrystalline ceramics (hardness HV 1500), the middle layer is a gradient toughening phase, and the core retains an elastic buffer zone. This design achieves an intelligent energy management mechanism of "impact-absorption-release.

3. Cleanliness Breakthrough: Through Henglihong's proprietary cyclone grading purification system, the free particulate content in the media is reduced to <5ppm (compared to the industry average of >50ppm), meeting the ISO 13485 medical device-grade cleanliness standard.

II. Performance Advantages: Redefining Industry Benchmarks

Based on joint test data from Henglihong's laboratory and the Institute of Metal Research, Chinese Academy of Sciences, the performance of ceramic beads has comprehensively surpassed that of traditional media, redefining industry benchmarks. The following is a comparison of the core indicators:

1. Cycle Life: Henglihong ceramic beads have a cycle life of 400-500 cycles (according to ASTM D968 standard), while traditional media have a cycle life of only 50-200 cycles.

2. Surface Roughness Control Precision: Henglihong ceramic beads can achieve customizable gradient control of surface roughness, ranging from Ra 0.05-6.3μm. In contrast, traditional media have a surface roughness control range of Ra 0.8-25μm.

3. Residual Stress: Henglihong ceramic beads can control residual stress to compressive stress levels of +5~+15MPa, whereas traditional media pose a risk of tensile stress ranging from -20~+50MPa.

4. Media Loss Rate: In a closed-loop system, the media loss rate of Henglihong ceramic beads is ≤0.3%/cycle, while traditional media have a loss rate of 1.5-5%/cycle.

Note: The above data is sourced from Henglihong's CNAS-certified laboratory report (No. HLH-TR-2023-026) released in 2023.

III. Application Scenarios: Empowering the Breakthroughs of "Made in China"

1. Aerospace Field:

Surface Treatment of Titanium Alloy Components for Domestic Large Aircraft C919: Using Henglihong's Φ100μm ceramic beads, a mirror-like surface finish with Ra 0.2μm was achieved under 0.25MPa pressure. The residual austenite content on the surface was reduced to below 3%, and the fatigue life was increased by 60%.

Stress Relief for Satellite Aluminum Alloy Shells: With Henglihong's intelligent blasting system, a uniform surface treatment of 5m² was completed within 120 seconds, with dimensional deformation controlled within ±0.01mm.

2. New Energy Vehicle Field:

Surface Treatment of 800V High-Voltage Battery Connection Plates: Henglihong's customized Φ50μm media removed the oxide layer from the copper foil while forming a 5nm-thick passivation film. The contact resistance was reduced by 22%, helping a leading domestic battery manufacturer achieve a yield rate of 99.8%.

Surface Strengthening of Integrated Die-Cast Vehicle Bodies: In collaboration with a new energy vehicle manufacturer, a combined ceramic bead-laser process was developed, increasing the tensile strength of 7-series aluminum alloy by 15% and achieving ASTM D3359 5B grade adhesion for electrophoretic paint.

3. High-End Electronics Manufacturing:

Precision Treatment of Folding Screen Phone Hinges: For a domestic flagship model, Henglihong's Φ30μm nano-ceramic beads achieved an ultra-fine surface with Ra 0.05μm under 0.05MPa ultra-low pressure. The friction coefficient was reduced to 0.12, and the hinge's open-close life exceeded 500,000 cycles.

Surface Roughening of Third-Generation Semiconductor Substrates: Henglihong's media constructed a micro-nano composite structure on the GaN substrate surface, increasing the silver paste bonding strength to 45MPa (compared to the industry benchmark of ≤30MPa), facilitating the mass production breakthrough of domestic RF devices.

Conclusion: How Can Hard-Core Technology Reshape the Value Chain of Surface Treatment?

From the wings of domestic large aircraft soaring in the sky to the precision hinges of folding screen phones, Henglihong's ceramic bead blasting media is writing a legend of quality in Chinese precision manufacturing. As the first domestic blasting media supplier to pass the IATF 16949 automotive-grade certification, we continue to use material innovation as the engine and intelligent solutions as the fulcrum to help our customers build core competitiveness on the micron-level track.

Jiangsu Henglihong Technology Co., Ltd. – Focused on Surface Treatment Innovation for 20 Years

National High-Tech Enterprise

12 Core Invention Patents

Customized Development Cycle Reduced to 7 Days

24/7 Online Technical Response

Contact our engineering team immediately to obtain a customized surface treatment solution!