#Industry News

What Are the Potential Applications of Ceramic Abrasive Media in the New Energy Vehicle Field?

Exploring the High-Tech Applications in NEV Manufacturing

With the rapid development of the new energy vehicle (NEV) industry, the demand for high-performance surface treatment technologies has increased significantly. Ceramic abrasive media, known for their high hardness, wear resistance, and environmental friendliness, are poised to play a crucial role in this sector. Below are some potential applications of ceramic abrasive media in the NEV field:

1. Surface Treatment of Battery Components

Battery systems in NEVs require high-quality surface treatment to ensure durability and performance. Ceramic abrasive media can be used to clean and prepare the surfaces of battery casings, connectors, and electrodes. This process removes contaminants and oxidation layers, enhances surface roughness, and improves the adhesion of protective coatings.

2. Lightweight Structural Components

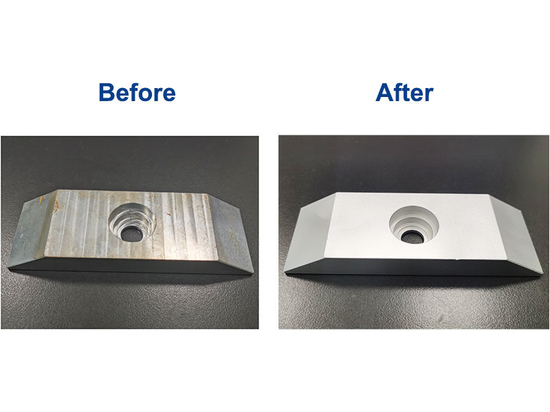

NEVs increasingly rely on lightweight materials to improve energy efficiency and range. Ceramic abrasive media can be used to treat lightweight components such as aluminum and magnesium alloys, which are commonly used in NEV chassis and body parts. The media can remove surface imperfections, increase surface hardness, and enhance fatigue resistance.

3. Surface Preparation for Coatings and Adhesives

In NEVs, components such as electric motor housings, gearboxes, and control units often require surface treatment to ensure the proper adhesion of coatings and adhesives. Ceramic abrasive media can provide a consistent surface profile, enhancing the durability and reliability of these components.

4. Enhancing Sensor Performance

NEVs rely heavily on various sensors for functions such as autonomous driving, battery management, and environmental monitoring. Ceramic abrasive media can be used to clean and prepare sensor surfaces, ensuring optimal performance and reliability. This is particularly important for sensors exposed to harsh environmental conditions.

5. Spray Polishing and Finishing

Ceramic abrasive media, such as zirconia beads, are used for spray polishing applications. These media can achieve high-quality surface finishes on materials like stainless steel, aluminum, and even plastics, providing a smooth and durable surface for NEV components.

6. Spray Peening for Fatigue Resistance

Ceramic abrasive media can be used in spray peening processes to enhance the fatigue resistance of critical components such as drive shafts, gears, and suspension parts. This process introduces compressive residual stresses into the surface, improving the component's ability to withstand cyclic loading.

7. Environmental and Sustainability Benefits

Ceramic abrasive media are environmentally friendly, producing minimal dust and requiring no chemical solvents. Their recyclability further reduces waste and environmental impact, aligning with the sustainability goals of the NEV industry.

Conclusion

What advantages do ceramic abrasive media offer for the surface treatment of components in new energy vehicles? Their ability to enhance surface quality, improve material performance, and ensure environmental sustainability makes them a valuable tool in the NEV manufacturing process. As the industry continues to evolve, the application of ceramic abrasive media is expected to expand, driving further innovation and efficiency in NEV production.