#Product Trends

The Application of Ceramic Sand Blasting in Glass Manufacturing

How Do Tiny Ceramic Grains Shape the "Super Surface" of Glass? Harnessing Microscopic Precision to Elevate Glass Manufacturing

In glass manufacturing, surface treatment is a key step in enhancing product performance and aesthetics. Traditional chemical etching and ordinary blasting techniques, though effective, come with issues such as environmental pollution and surface damage. What if there's a technology that can balance environmental friendliness, efficiency, and high quality? The answer is ceramic sand blasting. This article delves into the applications of ceramic sand blasting in glass manufacturing and reveals how it can bring a qualitative leap to glass surfaces.

1. The Core Advantages of Ceramic Sand Blasting

The core strengths of ceramic sand blasting lie in its unique physical and chemical properties, which make it stand out in glass surface treatment:

High Hardness and Low Wear: With a hardness of up to 700HV, ceramic sand lasts 20-30 times longer than glass beads. This high hardness not only ensures efficient surface treatment but also significantly reduces material costs.

Environmentally Friendly and Low Dust: Ceramic sand is less prone to breakage during blasting, producing minimal dust and ensuring a safer working environment for operators. Compared to traditional blasting materials, the eco-friendly nature of ceramic sand makes it the top choice for modern glass manufacturing.

High Surface Quality: The glass surface after blasting is smooth and uniform, significantly enhancing the product's aesthetics and fatigue resistance.

2. Specific Applications of Ceramic Sand Blasting in Glass Manufacturing

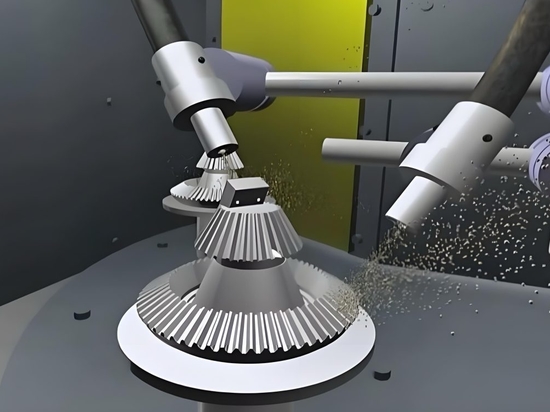

Ceramic sand blasting has a wide range of applications in glass manufacturing, covering almost every aspect from surface cleaning to strengthening treatments.

2.1 Frosted and Anti-Glare Treatment

Frosted Effect: By blasting micro-pits and textures on the glass surface, ceramic sand changes the reflection and refraction of light, achieving a frosted effect. This not only enhances the aesthetics of the glass but also improves its anti-glare performance.

Anti-Glare and Blue Light Reduction: Ceramic sand blasting can effectively reduce glare and blue light damage to the eyes, making it widely used in smartphone screens and computer monitors.

2.2 Surface Cleaning and Strengthening

Removing Impurities: Ceramic sand blasting efficiently removes oxidation layers, oil, and impurities from the glass surface, restoring its original color.

Surface Strengthening: During the blasting process, the high-speed impact of ceramic sand causes micro-plastic deformation on the glass surface, forming a cold-worked hardened layer that significantly improves the fatigue resistance of the glass.

2.3 Aesthetics and Decoration

Pattern and Text Processing: Ceramic sand blasting can be used for pattern engraving and text processing on glass surfaces, adding value to products.

Customized Effects: By adjusting the blasting pressure and particle size, a variety of effects from fine frosted to coarse textures can be achieved, meeting different design requirements for products.

3. The Versatility of Ceramic Sand Blasting

Ceramic sand blasting is not only applicable to glass manufacturing but also widely used in multiple fields, demonstrating its versatility:

Aerospace: Used for surface treatment of materials like aluminum and titanium alloys, significantly improving the fatigue resistance of parts.

Automotive Industry: Used for anti-glare treatment of automotive glass and surface decoration of interior components.

Electronics: Used for surface treatment of smartphone frames and screens, enhancing product aesthetics and durability.

Smart Home Devices: Used for surface treatment of smart devices, enhancing anti-glare and blue light reduction performance.

4. Future Outlook

With the continuous development of glass manufacturing technology, the application prospects of ceramic sand blasting are becoming even broader. In the future, ceramic sand blasting is expected to play an important role in the following areas:

5G Devices: With the popularization of 5G technology, ceramic sand blasting is set to become the mainstream process for surface treatment of smartphone casings and smart devices.

Environmental Sustainability: As environmental requirements increase, the low-pollution and recyclable nature of ceramic sand will make it the preferred material in the glass manufacturing industry.

Intelligent and Automated Processes: Future blasting processes will become more intelligent and automated, combining ceramic sand blasting technology with advanced equipment to achieve higher efficiency and more precise treatment effects.

Conclusion

Ceramic sand blasting, with its exceptional performance and wide range of applications, is becoming the new standard in glass manufacturing. Jiangsu Henglihong Technology Co., Ltd., as a leading company in the industry, is committed to providing high-quality ceramic sand blasting media and customized solutions to help drive the high-quality development of the glass manufacturing industry.

#CeramicSandBlasting #GlassManufacturing #SurfaceTreatment #EcoFriendlyTech #PrecisionEngineering