#Industry News

How Can Abrasive Media Revolutionize the 3D Printing Industry?

Exploring the Potential and Applications of Blasting Solutions in Additive Manufacturing

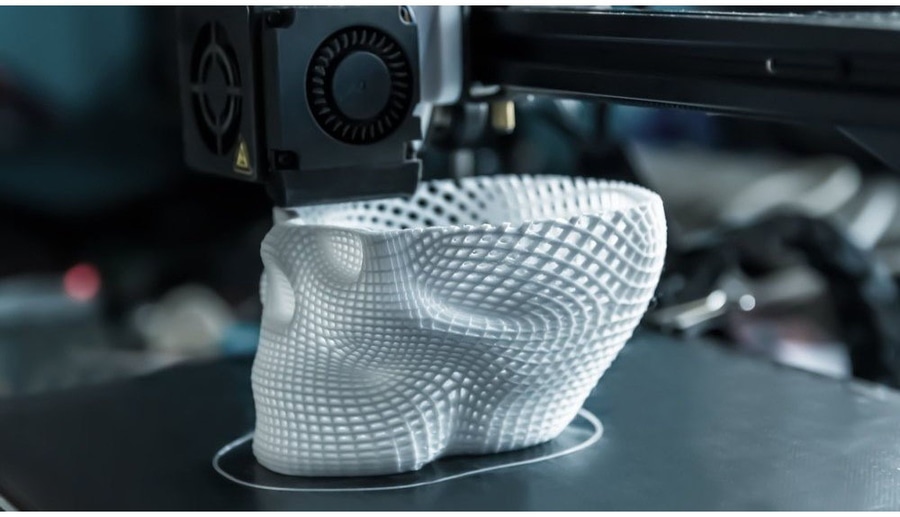

I. The Role of Abrasive Media in 3D Printing

Blasting technology, which involves propelling abrasive media at high speeds to impact and abrade surfaces, plays a crucial role in post-processing for 3D-printed parts. In the realm of 3D printing, the applications of abrasive media are diverse and essential:

Surface Cleaning and Powder Removal

After printing, 3D-printed parts often have residual powders or partially sintered layers on their surfaces. Blasting processes can efficiently remove these residues, leaving the parts clean. For example, systems like Formlabs' Fuse Blast can clean printed parts quickly, ensuring consistent results through pre-programmed processes.

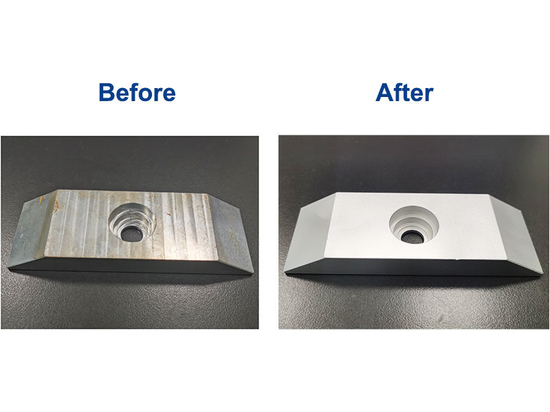

Surface Smoothing and Optimization

Beyond cleaning, abrasive media can be used to smooth surfaces and reduce roughness. By selecting the right media and process parameters, such as glass beads or plastic particles, the surface finish of 3D-printed parts can be significantly improved. This not only enhances the aesthetic quality but also improves mechanical properties.

Enhancing Mechanical Properties

Blasting can create a uniform micro-texture on the surface, which enhances lubrication, reduces wear, and extends the lifespan of components. Additionally, blasted surfaces are more receptive to coatings, further improving the corrosion and wear resistance of 3D-printed parts.

II. Choosing the Right Abrasive Media

The selection of appropriate blasting media is critical for achieving the desired post-processing effects. Common media include ceramic beads, glass beads, plastic particles, and alumina. The choice depends on the printing material, the intended use of the part, and the desired surface finish.

Ceramic Beads

Ceramic beads are highly durable and suitable for high-intensity surface treatment. They effectively remove surface residues and provide a uniform surface roughness, making them ideal for post-processing metal or high-performance plastic parts.

Glass Beads

Glass beads are softer and suitable for gentle surface treatment. They can smooth surfaces without damaging the base material, making them ideal for parts where a high surface finish is required.

Plastic Particles

Plastic particles are ideal for parts where surface hardness is less critical. They remove surface impurities while preserving the original texture, making them suitable for applications where a specific surface feel is desired.

III. Case Studies of Blasting in 3D Printing

Automotive Parts Manufacturing

In the automotive industry, blasting is widely used to process plastic, metal, and ceramic parts. The process enhances corrosion resistance and surface quality, meeting the stringent standards of the automotive sector.

Post-Processing for Selective Laser Sintering (SLS)

SLS-printed parts benefit significantly from blasting processes. Systems like Fuse Blast can quickly clean and smooth the surface, reducing particle roughness and minimizing manual labor.

Medical and Aerospace Applications

In high-precision industries like medical and aerospace, blasting ensures consistent surface treatment. By optimizing blasting parameters, parts achieve high surface smoothness and cleanliness, meeting industry standards.

IV. Technical Advantages of Jiangsu Henglihong Technology Co., Ltd.

As a leading company in the industry, Jiangsu Henglihong Technology Co., Ltd. specializes in providing high-quality blasting media and customized post-processing solutions. With advanced R&D capabilities and extensive industry experience, the company offers comprehensive support tailored to customer needs.

Customized Solutions

Jiangsu Henglihong Technology Co., Ltd. can tailor blasting media and process parameters to specific 3D printing materials and applications. For example, ceramic or glass beads of specific granules are recommended for high-precision SLS parts to achieve the best surface finish.

Technical Support and Services

The company offers full technical support, including equipment selection, operator training, and process optimization advice. By working closely with customers, Jiangsu Henglihong Technology Co., Ltd. ensures the efficient application of blasting processes in 3D printing post-processing, enhancing the overall quality and performance of printed parts.