#Product Trends

How Do Ceramic Bead Blasting Media Work Their Magic on Electronics?

Unveiling the Science Behind Ceramic Bead Blasting: How Tiny Beads Transform Electronic Components

In the rapidly evolving world of electronics, where precision and reliability are paramount, surface treatment is a crucial step in manufacturing. Ceramic bead blasting media, with its unique properties and versatile applications, has emerged as a game-changing solution for enhancing the performance and durability of electronic components.

The Role of Ceramic Bead Blasting in Electronics

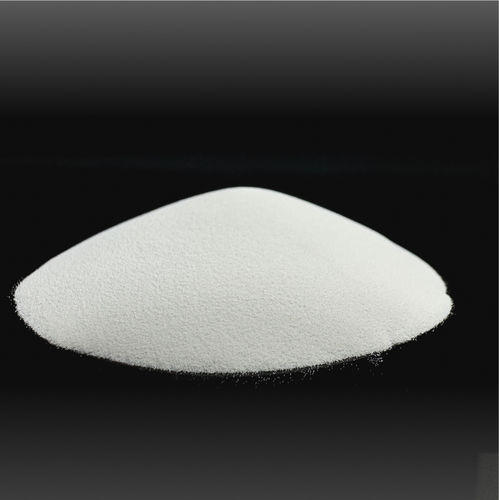

Ceramic bead blasting is a highly effective surface treatment technique that leverages the unique properties of ceramic beads to achieve superior surface quality. These beads, often made from materials like zirconia, are known for their high hardness, durability, and ability to provide a consistent, smooth finish without damaging the underlying material.

In electronics, ceramic bead blasting serves multiple critical functions:

Precision Cleaning: Ceramic beads can effectively remove contaminants, oxides, and residues from delicate electronic components without causing surface damage.

Surface Preparation: Before applying coatings or adhesives, ceramic bead blasting creates a uniform surface profile that enhances adhesion and ensures optimal performance.

Stress Relief and Strengthening: The blasting process can relieve residual stresses and improve the mechanical properties of components, making them more resistant to fatigue and wear.

How Ceramic Bead Blasting Works

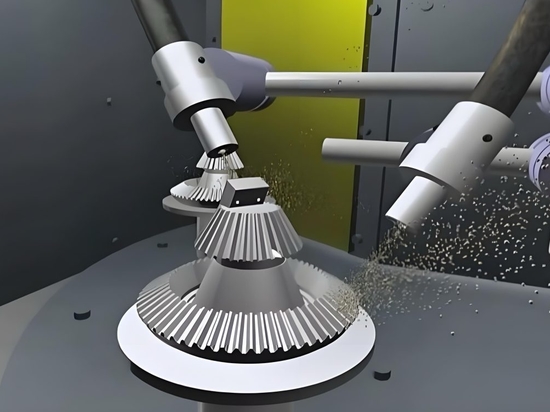

Ceramic bead blasting works by propelling tiny ceramic beads at high speed onto the surface of the workpiece. The beads impact the surface, removing contaminants and creating a controlled roughness. This process not only cleans the surface but also enhances its mechanical properties.

The key principles behind ceramic bead blasting include:

Impact and Abrasion: The beads impact the surface, removing contaminants and oxides.

Controlled Roughness: The beads create a uniform roughness that enhances adhesion for coatings and other treatments.

Non-Polluting: Ceramic beads are chemically inert and do not leave behind residues, ensuring that electronic components remain free from contamination.

Applications in Electronics

Ceramic bead blasting is widely used in various electronic manufacturing processes:

Microchips: Cleaning and preparing surfaces to ensure peak performance.

Circuit Boards: Removing solder residues to make way for new components.

Device Casings: Providing a smooth, durable finish that looks as good as it performs.

Why Ceramic Bead Blasting is Superior

Compared to traditional methods like chemical etching or mechanical grinding, ceramic bead blasting offers several advantages:

High Precision: The uniform size and shape of ceramic beads allow for highly controlled surface treatment, suitable for even the most intricate electronic parts.

Versatility: Ceramic bead blasting can be applied to a wide range of materials, including aluminum, stainless steel, titanium, and even plastics.

Environmental Friendliness: Ceramic beads are chemically inert and do not produce harmful residues, making the process environmentally friendly.

Jiangsu Henglihong Technology: Leading the Way

At Jiangsu Henglihong Technology, we specialize in high-quality ceramic bead blasting media tailored for the electronics industry. Our products are designed to meet the most stringent standards, ensuring that every component achieves optimal performance and reliability.

Our commitment to innovation and quality is backed by advanced manufacturing processes and rigorous testing. Whether you need precision cleaning, surface preparation, or stress relief, our ceramic bead blasting media are engineered to deliver consistent results every time.

Conclusion

Ceramic bead blasting is more than just a surface treatment technique; it’s a precision art that enhances the performance and longevity of electronic components. By choosing Jiangsu Henglihong Technology, you’re opting for precision, reliability, and innovation—key factors in the competitive world of electronics.

#CeramicBeadBlasting #ElectronicsSurfaceTreatment #PrecisionEngineering #JiangsuHenglihongTechnology #InnovationInElectronics