#Industry News

The Green Blast Revolution: Transforming Industry Through Eco-Friendly Abrasives

How Sustainable Blasting Media Is Reshaping Manufacturing While Protecting Our Planet

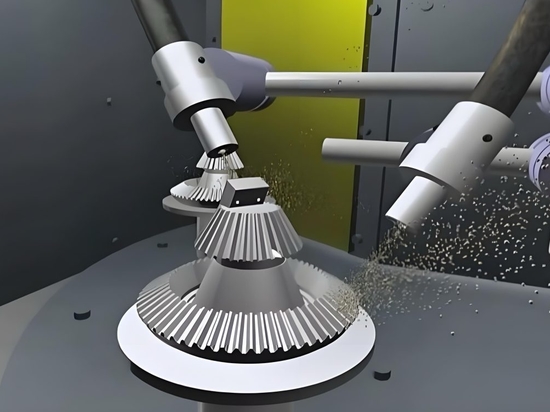

In today's industrial landscape, companies worldwide face increasing pressure to adopt sustainable practices while maintaining productivity and quality standards. Abrasive blasting, a widely used surface preparation technique across numerous industries, has traditionally relied on materials that pose significant environmental and health concerns. The shift toward eco-friendly blasting media represents not merely an optional green initiative but an inevitable direction for forward-thinking enterprises committed to sustainable development.

The Environmental Impact of Traditional Blasting Media

Conventional blasting materials such as silica sand, coal slag, and certain mineral abrasives have long been industry standards due to their effectiveness and relatively low cost. However, these materials present substantial environmental challenges:

Silica dust causes serious respiratory conditions including silicosis

Heavy metal contamination from coal slag can leach into soil and water systems

Limited recyclability leads to significant waste generation

High disposal costs and regulatory complications

Contribution to air pollution and particulate matter emissions

The Rise of Eco-Friendly Alternatives

The development of environmentally responsible blasting media has accelerated in recent years, driven by regulatory pressure, corporate sustainability goals, and technological innovation. These alternatives deliver comparable or superior performance while dramatically reducing environmental impact:

Recyclable Media Options

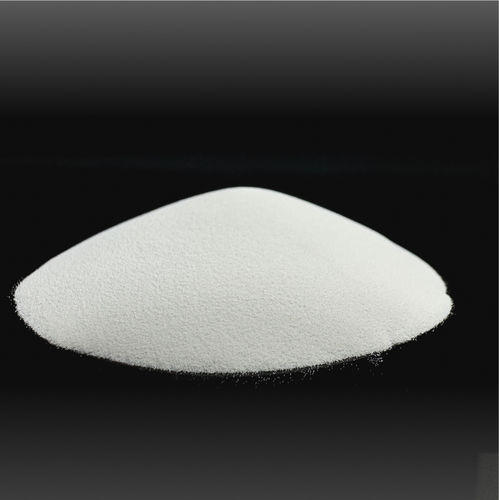

Soda blasting media (sodium bicarbonate)

Glass beads and crushed recycled glass

Walnut shell and other agricultural byproducts

Steel grit and shot with high reusability profiles

Plastic media specifically engineered for multiple use cycles

Key Environmental Advantages

Eco-friendly blasting media offer multiple sustainability benefits that align with modern corporate environmental responsibilities:

Reduced waste generation through multiple reuse cycles

Lower dust emissions and improved air quality

Elimination of silica exposure hazards

Biodegradability of certain plant-based media

Decreased water contamination risk

Smaller carbon footprint across the product lifecycle

Economic Benefits Supporting the Green Transition

While initial costs for eco-friendly media may be higher than traditional options, the comprehensive economic analysis demonstrates compelling advantages:

Reduced disposal costs through reusability

Lower regulatory compliance expenses

Decreased worker health-related liabilities

Enhanced corporate reputation and marketing opportunities

Improved access to environmentally conscious markets and contracts

Long-term cost stability as traditional media face increasing regulatory restrictions

Regulatory Trends Accelerating Adoption

Global environmental regulations continue to tighten regarding industrial processes and waste management:

Stricter silica exposure limits in workplace safety regulations

Increasingly stringent waste disposal requirements

Extended producer responsibility frameworks

Carbon pricing mechanisms affecting manufacturing inputs

Green procurement policies favoring sustainable processes

These regulatory developments make the transition to eco-friendly blasting media not simply a voluntary sustainability initiative but an essential business adaptation strategy.

Case Studies: Success in Implementation

Leading companies across multiple sectors have successfully transitioned to eco-friendly blasting media with notable results:

In automotive manufacturing, a major European producer reduced waste disposal costs by 67% by switching to recyclable steel media for parts preparation, while simultaneously improving surface quality consistency.

A North American shipyard's implementation of soda blasting technology for hull maintenance decreased environmental compliance costs while accelerating project completion times due to reduced cleanup requirements.

An aerospace components manufacturer adopted walnut shell media for precision cleaning applications, eliminating hazardous waste concerns while meeting stringent surface specification requirements.

Strategic Implementation Approaches

Companies considering the transition to eco-friendly blasting media should adopt a systematic approach:

Comprehensive performance evaluation across potential applications

Total cost analysis including disposal, regulatory, and health considerations

Phased implementation beginning with less critical applications

Staff training on new material handling and recycling protocols

Supplier partnerships focused on sustainability metrics

Integration with broader corporate environmental management systems

Conclusion

The shift toward eco-friendly blasting media represents more than an environmental preference—it constitutes a necessary evolution in industrial surface preparation technology. As regulatory frameworks continue to emphasize sustainability, resource efficiency, and pollution reduction, companies proactively adopting green blasting alternatives position themselves advantageously for future market conditions.

This transition aligns environmental responsibility with operational efficiency and long-term economic viability. Forward-thinking enterprises recognize that eco-friendly blasting media are not merely a temporary trend but a fundamental component of modern sustainable manufacturing practice—the inevitable direction for companies committed to responsible production in a resource-constrained world.