#Industry News

Ceramic Shot Peening: The Microscopic Hammers Extending Component Life by 300%

The Transformative Impact of Ceramic Shot Peening on Industrial Applications

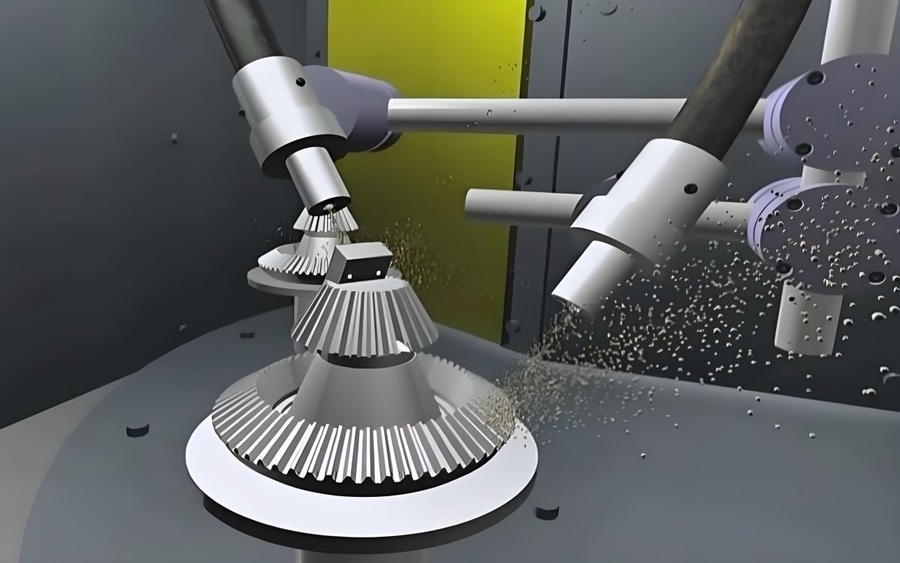

Ceramic shot peening has emerged as an advanced surface treatment process that significantly enhances component fatigue resistance across aerospace, automotive, medical, and power generation industries. While conventional steel shot peening has been an industry standard for decades, ceramic media offers unique advantages that directly translate to superior fatigue life enhancement. This article explores the mechanisms and benefits of ceramic shot peening for extending component service life.

The Fundamentals of Ceramic Shot Peening

Shot peening is a cold working process where small spherical media impact material surfaces at high velocity, inducing compressive residual stresses. Ceramic shot peening utilizes beads typically composed of zirconia, alumina, or silicon nitride.

Key Advantages of Ceramic Media

Superior hardness-to-density ratio: Lighter than steel while maintaining excellent hardness

Chemical inertness: Resists corrosion with no metallic residue

Exceptional durability: Maintains spherical shape longer for consistent results

Clean process: Produces less dust and contamination

The Science Behind Fatigue Life Enhancement

Compressive Residual Stress Induction

Ceramic beads create a layer of compressive residual stress that extends deeper beneath the surface compared to steel media. These compressive stresses act as barriers to crack initiation and propagation—the primary mechanisms of fatigue failure.

Microstructural Refinement

The process induces plastic deformation resulting in:

Grain refinement

Increased dislocation density

More uniform microstructures

These changes disrupt crack initiation mechanisms and create more tortuous paths for potential crack propagation.

Surface Texture Optimization

Ceramic media creates an optimal surface finish that balances:

Sufficient roughness for lubricant retention

Smooth valleys to avoid stress concentration points

Uniform coverage without excessive cold working

Process Parameters Influencing Fatigue Life

Media Selection

Zirconia: Exceptional durability for high-value components

Alumina: Excellent hardness for treating harder materials

Silicon nitride: Superior performance in extreme temperature applications

Peening Intensity

Proper control of Almen intensity is crucial:

Optimal ranges typically between 0.08-0.24 mmA

Coverage levels of 98-200% provide the best results

Multiple-pass techniques can create tailored stress profiles

Process Control

Achieving consistent results requires:

Real-time velocity monitoring

Automated coverage verification

Computer-controlled nozzle movement

Statistical process control

Material-Specific Benefits and Case Studies

Aerospace Titanium Alloys

Ti-6Al-4V compressor blades: 270% fatigue life extension

Landing gear components: 180% improvement in crack resistance

One manufacturer reported $3.2 million in annual savings through extended component life

Automotive Steel Applications

Transmission gears: 200-250% fatigue life extension

Connecting rods: 150% improvement in fatigue resistance

Valve springs: 300% increase in service life

75% reduction in warranty claims reported by one premium manufacturer

Medical Implant Materials

Stainless steel implants: 200% improvement in fatigue life

Cobalt-chrome components: 170% enhancement in fretting resistance

Avoids metallic contamination issues critical in biomedical applications

Advanced Implementation Strategies

Hybrid Processing

Combining ceramic shot peening with other treatments creates synergistic effects:

Ceramic peening + laser shock peening

Pre-nitriding + ceramic peening

Ceramic peening + isotropic finishing

Targeted Peening

Advanced strategies focus treatment on specific high-stress regions:

FEA-guided intensity mapping

Masked peening techniques

Gradient peening approaches

Computational Optimization

Digital tools have revolutionized implementation:

Predictive modeling

Machine learning algorithms

Digital twins for fatigue behavior prediction

Economic Impact

Ceramic shot peening delivers compelling economic benefits:

Extended component service life reduces replacement costs

Enhanced properties enable lighter designs

Fewer in-service failures reduce warranty costs

ROI periods typically range from 6-18 months

Future Directions

Promising developments include:

Nano-ceramic media for precision applications

Cryogenic ceramic peening

Smart ceramic media providing real-time feedback

Multifunctional ceramics inducing beneficial surface chemistry changes

Conclusion

Ceramic shot peening represents a significant advancement in surface treatment technology for enhancing component fatigue life. Through optimized compressive residual stresses, microstructural refinement, and ideal surface texturing, this process delivers substantial improvements in component durability. For engineers facing fatigue-related challenges, ceramic shot peening offers a proven, cost-effective solution that extends service life and enhances overall product performance.