#Product Trends

Can Plastic Blasting Media Revolutionize Tantalum Capacitor Deburring?

The Game-Changing Two-Stage Approach That Delivers 95% Burr Removal Without Component Damage

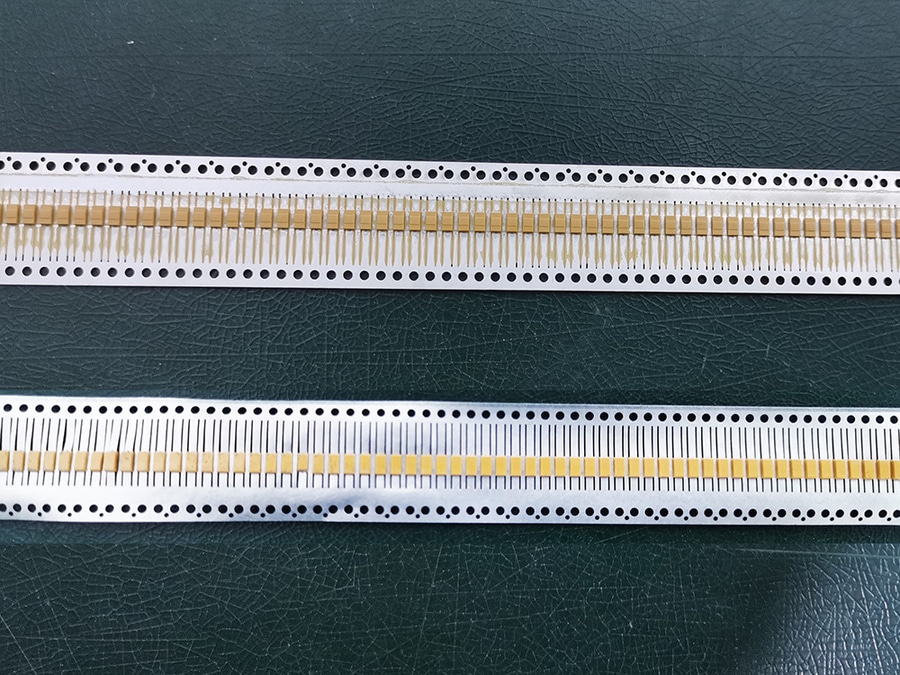

Tantalum capacitors are valued in aerospace, medical equipment, and communications for their reliability ✓. However, manufacturing burrs cause performance issues and failures ⚠. Plastic media, particularly melamine and urea-formaldehyde, provide precise deburring solutions where traditional methods fail.

1. Technical Challenges

During manufacturing processes, microscopic burrs form on capacitor surfaces and lead interfaces, causing:

Electric field concentration

Short circuit risks

Encapsulation defects

Reliability degradation

Traditional methods damage dielectric layers or fail to reach complex geometries.

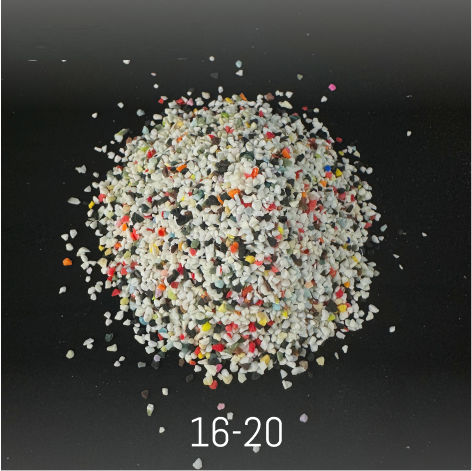

2. Material Properties

Melamine Media

Hardness: 3.5-4.0 Mohs

Sharp polyhedral particles

Density: 1.57g/cm³

Chemically stable

Heat resistant to 350°C

Urea-Formaldehyde Media

Hardness: 2.8-3.5 Mohs

Spherical/ellipsoidal particles

Density: 1.45g/cm³

Low moisture absorption

Reduced ESD risk

3. Process Parameters

Pressure: Melamine (1.8-2.5bar), Urea-formaldehyde (1.5-2.2bar)

Distance: 15-25cm ideal

Particle Size: Coarse (80-100 mesh), Fine (120-150 mesh)

Processing Time: 20-60 seconds

Angle: Surface (45°-60°), Lead connections (75°-85°)

Proper control achieves 95%+ burr removal without damage.

4. Application Strategy

Melamine Best For:

Larger capacitors

Severe burrs

Welding areas

Low-voltage products

Urea-Formaldehyde Best For:

Miniature capacitors

High-voltage products

Surface finishing

Precision areas

Optimal Approach: Two-stage process using melamine followed by urea-formaldehyde, improving efficiency by 30% while reducing damage risk.

#ElectronicComponents #ManufacturingTechnology #TantalumCapacitors #SurfaceTreatment #QualityControl #ManufacturingDefects #ElectricalFailure #ProductReliability #MaterialScience #PolymerPropert