#Industry News

Ceramic Bead Sandblasting: The Magical Media Revolutionizing Surface Pre-Treatment

Harnessing the Potential of Ceramic Beads: Revolutionizing Surface Pre-Treatment Across Industries

1. Introduction: The Rise of Ceramic Bead Media in Surface Pre-Treatment

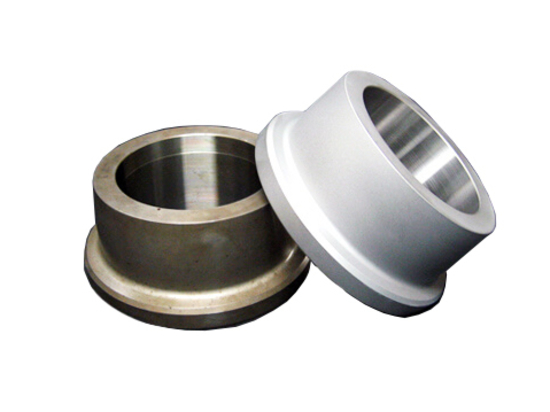

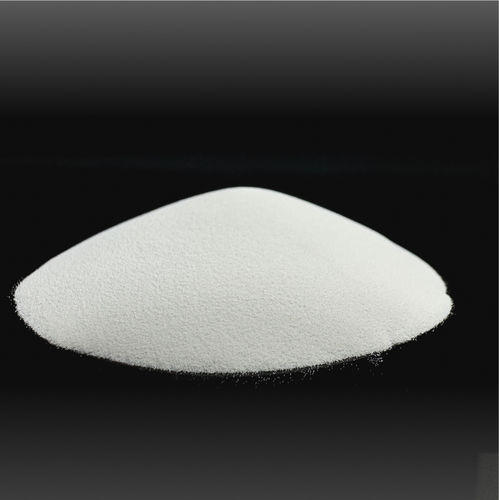

Surface treatment plays a vital role in improving the performance, durability, and appearance of materials. Among the various methods, ceramic bead sandblasting has emerged as a revolutionary technology in surface pre-treatment. Ceramic beads are gaining popularity due to their efficiency, environmental benefits, and durability. They are ideal for removing oxidation layers, improving coating adhesion, and enhancing surface smoothness across industries like aerospace, automotive, medical devices, and electronics.

2. Advantages of Ceramic Bead Sandblasting

2.1 Durability

Ceramic beads are made from hard, dense materials that ensure long-lasting performance. They have a significantly longer lifespan compared to other media, reducing the need for frequent replacements and lowering costs.

2.2 Uniform Surface Finish

The spherical shape of ceramic beads ensures an even distribution of impact, resulting in a smooth and uniform surface finish. This is especially important in industries that require high precision, such as aerospace and medical devices.

2.3 Environmental and Safety Benefits

Ceramic beads produce less dust and are non-toxic, making them a safer and more eco-friendly choice than traditional blasting media like silica sand.

3. Key Applications of Ceramic Bead Sandblasting

3.1 Aerospace

In aerospace, ceramic beads are used to remove oxidation layers and casting defects from turbine blades and engine components, improving fatigue strength and corrosion resistance for longer-lasting parts.

3.2 Automotive

Ceramic bead sandblasting is used in the automotive industry to prepare and finish aluminum wheels, brake rotors, and engine parts. It enhances coating adhesion, removes oxidation, and improves overall durability and appearance.

3.3 Medical Devices

For medical devices, ceramic beads are used to clean and smooth implants and surgical tools, improving biocompatibility and surface quality to reduce the risk of rejection or infection.

3.4 Electronics

In the electronics industry, ceramic beads effectively clean PCBs and semiconductor parts without damaging the delicate components, ensuring high precision in the manufacturing process.

3.5 Steel Industry

Ceramic beads are used to remove scale and rust from steel surfaces, improving surface roughness for better coating adhesion and corrosion resistance.

4. Important Factors in Choosing Ceramic Bead Media

4.1 Particle Size and Shape

The size and shape of ceramic beads affect the sandblasting results. Smaller beads are best for polishing and fine cleaning, while larger beads are suitable for removing thick oxidation layers and deburring.

4.2 Blasting Pressure and Flow Rate

Adjusting the blasting pressure and flow rate ensures optimal results. Higher pressures are used for heavy-duty applications, while lower pressures are ideal for delicate surface finishes.

5. Conclusion: The Future of Ceramic Bead Sandblasting

Ceramic bead sandblasting is becoming a preferred choice for surface pre-treatment due to its efficiency, durability, and environmental benefits. From aerospace to automotive and medical devices, its applications continue to grow. With ongoing technological advancements and stricter environmental regulations, ceramic bead sandblasting will remain an essential part of surface treatment in the future.

#CeramicBeads #SandblastingMedia #SurfacePreTreatment #Aerospace #Automotive #MedicalDevices #Electronics #EcoFriendly #SurfaceTreatment