#Industry News

Industrial Applications and Prospects of Micron-Level Ceramic Bead Blasting Technology

Exploring the Future of Precision Surface Treatment in Manufacturing with Micron-Level Ceramic Bead Blasting Technology

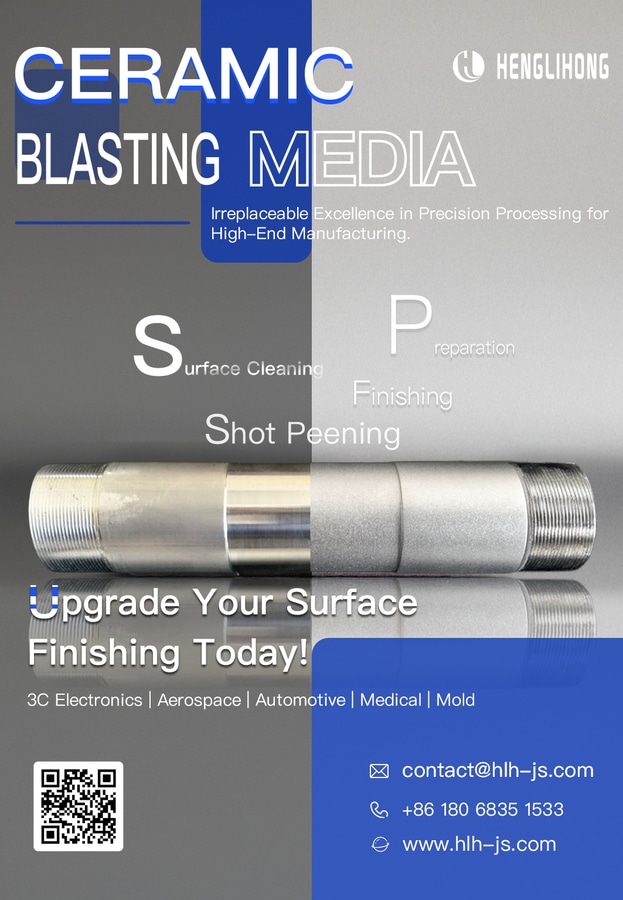

In the field of modern precision manufacturing, surface treatment technology plays a crucial role. With the increasing demands for surface quality in high-tech industries such as electronics, aerospace, and medical devices, traditional blasting technologies can no longer meet the processing requirements at the micron level. Micron-level ceramic bead blasting technology, as an emerging high-precision surface treatment method, is gradually becoming an indispensable process in precision parts manufacturing. This article will thoroughly analyze the principles, applications, and development trends of this technology.

1. Technical Principles

1.1 Material Characteristics of Micron-Level Ceramic Beads

Micron-level ceramic beads are primarily made from high-hardness ceramic materials such as zirconium oxide (ZrO₂), aluminum oxide (Al₂O₃), or silicon carbide (SiC), with diameters typically ranging from 5 to 100 microns. These materials possess the following characteristics:

Ultra-high hardness: Mohs hardness of 8-9.5, approaching that of diamond

Excellent sphericity: Sphericity exceeding 98%, ensuring uniform contact surfaces

Chemical stability: Acid and alkali resistant, non-reactive with most metals

Dimensional precision: Uniform particle size distribution with standard deviation controlled within ±1μm

1.2 Working Mechanism

Micron-level ceramic bead blasting technology uses high-pressure air or liquid flow as a carrier to project micron-level ceramic beads onto the workpiece surface at precisely controlled speeds (20-120m/s) and angles (15°-90°). The microscopic impact effects produced by the collision of ceramic beads with the surface achieve precise modification of the surface:

Micro-cutting: The edges of ceramic beads perform micro-cutting on the surface, removing nanometer-level surface layers

Plastic deformation: Impact forces create microscopic plastic deformation on the material surface, increasing surface hardness

Nano-compressive stress: Forms a compressive stress field in the surface layer, improving fatigue strength

Surface activation: Increases surface active sites, enhancing subsequent coating adhesion

2. Equipment and Process Parameters

2.1 Core Equipment Components

Modern micron-level ceramic bead blasting systems typically include the following components:

High-precision pressure control system: Pressure fluctuation controlled within ±0.01MPa

Micron-level powder classification device: Ensures particle size consistency

Digital nozzle control system: Precisely controls projection angle and distance

Optical real-time monitoring system: Monitors processing effects and adjusts parameters in real-time

Environmental control unit: Temperature controlled at 20±2℃, humidity at 45±5%

2.2 Key Process Parameters and Control

Parameter, Control Range, Influencing Factors

Blasting Pressure: 0.1-0.8MPa, Surface roughness, processing efficiency

Bead Diameter: 5-100μm, Surface morphology, microstructure

Projection Angle: 15°-90°, Impact force direction, material removal rate

Projection Distance: 10-100mm, Energy distribution, treatment uniformity

Processing Time: 5-300s, Surface integrity, processing depth

Bead Flow Density: 2-20g/min·cm², Processing efficiency, surface quality

Precise control of these parameters is crucial for achieving ideal surface effects. Modern systems typically employ AI algorithms to assist parameter optimization, automatically generating optimal parameter combinations based on material characteristics and processing requirements.

3. Application Fields

3.1 Semiconductor and Microelectronics Industry

Precision lead frame processing: Increases bonding strength by 30-50%

Microelectromechanical systems (MEMS) cleaning: Removes microscopic contaminants, improving yield by up to 15%

Integrated circuit packaging substrate treatment: Enhances surface wettability, improving soldering reliability

3.2 Aerospace Field

Gas turbine blade strengthening: Increases blade fatigue life by up to 40%

Precision hydraulic component treatment: Reduces friction coefficient, extending service life

Aerospace fastener surface treatment: Improves hydrogen embrittlement resistance and corrosion resistance

3.3 Medical Devices

Implant surface modification: Enhances osseointegration, improves biocompatibility

Dental implant treatment: Creates microstructures that promote tissue growth

Precision medical device components: Removes micro-burrs, improving safety

4. Technical Advantages and Limitations

4.1 Advantages Over Traditional Blasting Technologies

Improved processing precision: Can achieve nanometer-level surface modification, with Ra values controllable within 0.05-1.2μm

Surface integrity: Produces virtually no microcracks or stress concentrations

Repeatability: Batch-to-batch consistency exceeding 95%

Environmental friendliness: Ceramic materials can be recycled, reducing waste generation

Precise area control: Can achieve micron-level selective area treatment

4.2 Technical Limitations and Challenges

Equipment investment cost: Professional equipment typically requires an investment of 500,000-2,000,000 yuan

Narrow process window: High parameter control requirements, difficult operation

Adaptability issues for specific materials: Such as ultra-soft materials or certain composites

Production efficiency: Smaller area treated per unit time compared to traditional methods

5. Latest Technology Development Trends

5.1 Intelligence and Digital Twins

AI-assisted parameter optimization: Reduces trial and error time by up to 85%

Digital twin technology: Real-time simulation of the blasting process, predicting surface quality

Adaptive control systems: Automatically adjusting process parameters based on real-time feedback

5.2 New Ceramic Materials

Core-shell structured ceramic microbeads: Combining high hardness and toughness

Nano-composite ceramics: Improving wear resistance and chemical stability

Functionalized ceramic beads: Surface modification with specific functional groups, achieving chemical activation

5.3 Composite Process Integration

Electrochemical-assisted micro-blasting: Combining electrochemical effects to improve material removal efficiency

Laser-enhanced ceramic blasting: Using laser pre-treatment to improve processing precision

Ultrasonic-assisted technology: Enhancing microbead impact effects while reducing projection pressure

6. Case Study: Aero-Engine Blade Treatment

An aero-engine manufacturer adopted micron-level ceramic beads (ZrO₂, 20±2μm) to treat high-temperature alloy turbine blades, achieving the following significant results:

Surface roughness optimized from Ra 1.8μm to Ra 0.4μm

Surface hardness increased by 42%, from HV320 to HV455

Surface compressive stress layer depth reached 25μm, improving fatigue life by 35%

Thermal barrier coating adhesion improved by 50%, extending service life by 2,000 hours

Production efficiency increased by 20%, with a 75% reduction in processing rework rate

This case fully validates the superior performance of micron-level ceramic bead blasting technology in high-end precision parts surface treatment.

7. Process Implementation Guide and Quality Control

7.1 Process Implementation Workflow< strong>

Pre-treatment: Ultrasonic cleaning to remove oil and particulate matter

Parameter design: Setting initial parameters based on material characteristics and requirements

Sample validation: Small batch testing and surface analysis

Formal processing: Controlling environmental conditions, executing blasting operations

Quality inspection: Surface roughness, morphology, and performance testing

Post-treatment: Neutralizing the surface, removing residual ceramic particles

7.2 Quality Control and Testing Methods

Test Item, Testing Equipment, Control Standard

Surface Roughness: Laser Confocal / Microscope, Ra ±0.05μm

Surface Morphology: Field Emission SEM, No microcracks, uniform particle distribution

Compressive Stress Layer: X-ray Stress Analyzer, Stress value -300±30MPa

Surface Hardness: Nano-indentation Tester, Hardness deviation <5%

Surface Activity: Contact Angle Meter, Contact angle reduction >40%

Conclusion

As a cutting-edge process for precision parts surface treatment, micron-level ceramic bead blasting technology continues to break the limitations of traditional processing, providing powerful technical support for high-tech manufacturing industries. Its applications in aerospace, medical devices, semiconductors, and other fields have strongly promoted technological progress in these industries. With the development of intelligent manufacturing and new material technologies, micron-level ceramic bead blasting technology will further integrate advanced concepts such as artificial intelligence and digital twins to achieve higher precision and more efficient surface treatment, bringing new development opportunities for precision manufacturing.

When introducing this technology, enterprises need to comprehensively consider investment costs, technical requirements, and application scenarios to formulate reasonable implementation strategies to fully leverage its potential in product quality improvement and cost optimization.

Keywords: #MicronCeramicBeads #BlastingTechnology #SurfaceTreatment #PrecisionManufacturing #Aerospace #MedicalDevices