#Industry News

Freezing the Future: The Industrial Transformation of Polycarbonate Cryogenic Deflashing Technology

Pioneering Precision at the Boundaries of Material Science

Polycarbonate cryogenic deflashing pellet media represents a pivotal innovation in modern precision manufacturing, playing a crucial role in industrial production. This article will delve into the application fields, mechanism, and unique advantages of this cutting-edge material.

1. Material Basic Characteristics

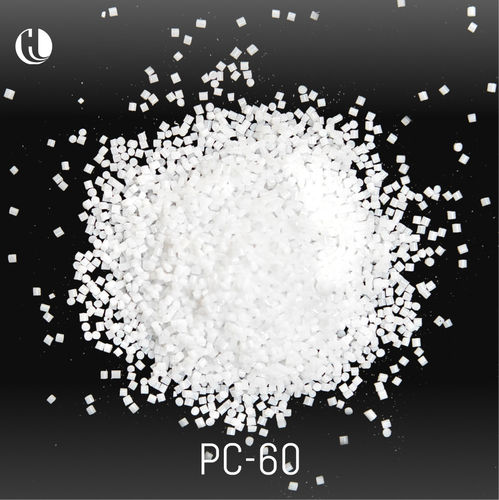

Polycarbonate cryogenic deflashing pellet media is a high-performance engineering plastic medium with the following key features:

Exceptional mechanical properties: High strength, excellent toughness, and impact resistance

Excellent heat resistance with a wide temperature range

Strong chemical stability and corrosion resistance

Superior processability

2. Primary Processing Materials

The cryogenic deflashing pellet media can process a wide range of materials, primarily including:

2.1 Metal Materials

Aluminum alloys: Aerospace and automotive components

Copper alloys: Electronic components, precision machinery

Stainless steel: Medical devices, food processing equipment

Titanium alloys: Aerospace, medical implants

2.2 Engineering Plastics

Polyether ether ketone (PEEK): High-performance industrial parts

Polyimide (PI): Electronics, aerospace applications

Nylon (PA): Mechanical components, automotive elements

Polycarbonate (PC): Optical components, electronic enclosures

2.3 Special Ceramic Materials

Zirconia ceramics: Precision instruments, medical devices

Alumina ceramics: Wear-resistant parts, electronic components

Silicon carbide ceramics: High-temperature, high-pressure components

2.4 Composite Materials

Carbon fiber reinforced composites: Aerospace, sports equipment

Fiberglass reinforced materials: Automotive, construction industries

Aramid fiber composites: Bulletproof vests, aerospace parts

3. Application Fields

3.1 Precision Casting and Demolding

In the precision casting industry, this pellet media is primarily applied to:

Metal casting surface treatment

Demolding of complex-shaped parts

Reduction of casting surface burrs and residues

3.2 Medical Device Manufacturing

Widely adopted in the medical industry:

Precision surgical instrument surface treatment

Fine processing of implant components

Ensuring smooth surface and precision of medical devices

3.3 Automotive Parts Production

Key applications in automotive manufacturing:

Precision mechanical parts demolding

High-precision engine component surface treatment

Reducing part processing errors

3.4 Aerospace Industry

Plays a critical role in aerospace:

Complex structural component surface treatment

High-performance part precision processing

Reducing subsequent mechanical processing costs

4. Technical Advantages

Efficient Demolding: More uniform and efficient compared to traditional mechanical demolding methods

Low-Temperature Environment: Demolding at low temperatures, avoiding thermal damage to materials

Surface Quality: Significantly improving part surface smoothness and precision

Environmentally Friendly: Reducing chemical processing, lowering environmental pollution

5. Operational Process

Typical low-temperature demolding process:

Select appropriate particle size of polycarbonate particles

Control low-temperature environment (typically -50°C to -80°C)

Precisely control particle and workpiece interaction time and intensity

Cleaning and surface treatment

6. Process Parameter Control

6.1 Temperature Control

Low-temperature range: -50°C to -80°C

Temperature fluctuation control: ±2°C

Cooling rate: 5-10°C per minute

6.2 Particle Parameters

Particle size range: 0.3-1.2 mm

Hardness: Shore hardness 45-55

Particle shape: Near-spherical, smooth surface

6.3 Processing Time

Thin-wall parts: 3-5 minutes

Complex structural parts: 5-10 minutes

Large parts: 10-15 minutes

Polycarbonate cryogenic deflashing pellet media represents a significant breakthrough in modern precision manufacturing technology, demonstrating excellent application value in multiple high-precision industrial fields. As technology continues to advance, its application prospects will become even broader.

#PrecisionManufacturing #CryogenicTechnology #SurfaceTreatment #EngineeringMaterials #AdvancedManufacturing #PolycarbonateMedia #IndustrialInnovation #MaterialScience