#Industry News

Yttria-Stabilized Zirconia Beads: Innovative Applications in Dispersion Grinding and Shot Peening Strengthening

Key Material Applications for Enhancing Processing Efficiency and Material Performance

Yttria-stabilized zirconia (YSZ) beads, as a high-performance ceramic material, have shown great potential in various industrial fields due to their high strength, hardness, and resistance to high temperatures. In recent years, with the continuous advancement of material processing technologies, YSZ beads have been increasingly applied in dispersion grinding and shot peening strengthening, playing a significant role in enhancing processing efficiency and improving material performance. This article will delve into the applications and advantages of YSZ beads in these two fields and explore their future development trends.

1. Basic Properties of Yttria-Stabilized Zirconia Beads

YSZ beads are primarily composed of zirconia (ZrO2) and yttria (Y2O3). The doping of yttria stabilizes the cubic crystal structure of zirconia, allowing it to maintain excellent physical and chemical stability at high temperatures. The main characteristics of YSZ beads include:

Excellent Mechanical Strength and Hardness: YSZ beads exhibit high hardness and strength, enabling them to withstand significant impact and friction, making them suitable for high-strength working environments.

Strong Wear Resistance: Due to their hardness, YSZ beads possess remarkable wear resistance and can work stably in high-abrasion environments for extended periods.

High-Temperature Stability: YSZ beads can maintain stability under extreme temperatures, making them suitable for high-temperature applications.

Chemical Stability: YSZ beads exhibit excellent corrosion resistance, making them suitable for complex chemical environments.

These excellent physical and chemical properties make YSZ beads an irreplaceable material in both dispersion grinding and shot peening strengthening.

2. Applications of Yttria-Stabilized Zirconia Beads in Dispersion Grinding

Dispersion grinding is a widely used technology in material processing that aims to evenly disperse solid particles in a liquid through the high-speed collisions and frictional effects of grinding media. YSZ beads offer several advantages in this field:

Improved Dispersion Effect: Due to their high hardness and smooth surface, YSZ beads can effectively break large particles, reduce particle agglomeration, and improve the dispersion efficiency. This makes them widely used in industries such as pigments, coatings, cosmetics, and more.

Enhanced Grinding Efficiency: YSZ beads, with their strong mechanical strength, can participate in the grinding process efficiently for extended periods, reducing wear caused by material fatigue and extending their service life, which ultimately increases overall processing efficiency.

Suitability for High-Viscosity Systems: Compared to conventional grinding media, YSZ beads, due to their higher hardness and density, can effectively disperse liquids with high viscosity, such as resins and paints, ensuring uniformity and consistency in the grinding process.

Improved Product Quality: YSZ beads help reduce inhomogeneity and particle sedimentation during the dispersion process, which ultimately improves the homogeneity and stability of the final product, making them particularly important in high-end coatings, pharmaceuticals, and food processing.

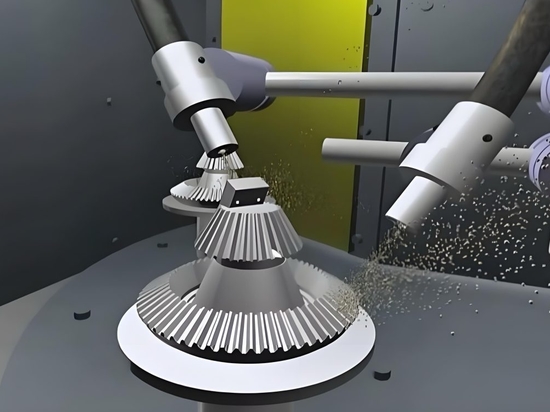

3. Applications of Yttria-Stabilized Zirconia Beads in Shot Peening Strengthening

Shot peening is a process that involves the high-speed impact of hard particles on the surface of metals, generating compressive stresses that enhance the fatigue and crack resistance of the material. YSZ beads, due to their excellent mechanical properties and wear resistance, are widely applied in shot peening strengthening, with the following benefits:

Increased Surface Hardness: YSZ beads can improve the surface hardness of metals through impact, which is particularly effective in surface treatments of high-strength steels and aluminum alloys. This increases wear resistance and extends the life of components.

Optimized Surface Residual Stresses: Shot peening generates compressive stress layers on the metal surface, which significantly improves fatigue life and crack propagation resistance. YSZ beads ensure that the generated compressive stresses are more uniform and stable, thus improving the overall peening effect.

Suitability for High-Temperature Environments: The high-temperature resistance of YSZ beads allows them to work stably at elevated temperatures, making them ideal for shot peening in high-temperature applications such as aerospace and automotive engine components.

Improved Surface Finish: The smooth surface of YSZ beads helps minimize unwanted scratches during shot peening, ensuring a higher-quality surface finish. This is especially important in applications where surface precision is critical.

4. Advantages of Yttria-Stabilized Zirconia Beads in Dispersion Grinding and Shot Peening

Durability: The hardness and wear resistance of YSZ beads ensure they have a long service life in both dispersion grinding and shot peening, compared to other common materials.

Efficiency: YSZ beads improve processing efficiency in both dispersion grinding and shot peening, reducing material consumption while maintaining consistent processing quality.

Wide Adaptability: YSZ beads can perform well in both standard and extreme environments (such as high-temperature, high-pressure, or corrosive conditions), meeting the needs of various industrial applications.

5. Future Development Trends

With the continuous progress of technology, the applications of YSZ beads in dispersion grinding and shot peening are expected to expand further. Particularly in advanced industries such as precision machining, aerospace, automotive manufacturing, and biomedical materials, the unique advantages of YSZ beads will further enhance their market competitiveness. Additionally, with the development of nanotechnology and surface engineering, the preparation processes and performance of YSZ beads will continue to be optimized, driving their wider adoption in various industrial applications.

Conclusion

Yttria-stabilized zirconia beads, due to their excellent physical and chemical properties, have demonstrated tremendous potential in dispersion grinding and shot peening strengthening. Their high hardness, wear resistance, and high-temperature stability make them ideal choices in these fields. As technology continues to advance, the application prospects of YSZ beads will become broader, making them an essential tool for enhancing production efficiency and material performance in numerous industries.

Tags: Yttria-Stabilized Zirconia Beads, Dispersion Grinding, Shot Peening Strengthening, Material Processing, High-Performance Ceramics, Industrial Applications, Surface Treatment, Wear Resistance