#Product Trends

How Can Z-Series Ceramic Shot Peening Media Revolutionize Aerospace and Automotive Performance?

How Z-Series Ceramic Shot Peening Media are Revolutionizing Surface Treatment in Aerospace and Automotive Applications

1. The Importance of Surface Integrity in Aerospace and Automotive Industries

In both aerospace and automotive industries, components are subjected to extreme stress, high pressure, and fatigue during operation. For instance, aircraft engines, turbine blades, and automotive components such as crankshafts and suspension systems must withstand severe operational conditions. If the surface of these components is not properly treated, the materials can be prone to cracks, fatigue, and premature failure.

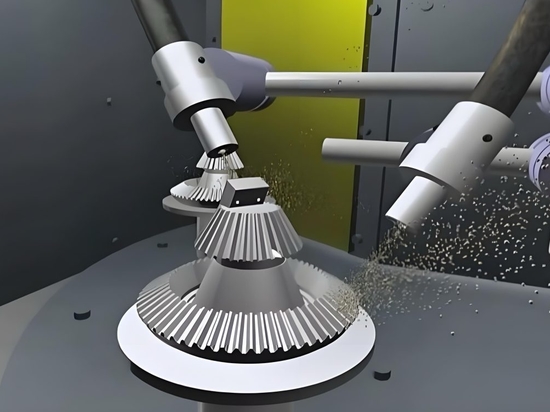

Surface treatments like shot peening are essential for improving the strength, fatigue resistance, and durability of these parts. Shot peening involves bombarding the surface of a part with small media (in this case, ceramic shot) to induce compressive residual stresses, thereby enhancing the material’s ability to resist cracking and fatigue under cyclic loading.

2. Z-Series Ceramic Shot Peening Media: What Makes Them Special?

Z-Series ceramic shot peening media are specifically designed to meet the demanding needs of modern aerospace and automotive applications. They offer several distinct advantages over traditional metal-based shot peening media, such as steel or glass beads.

Key Features of Z-Series Ceramic Media:

High Hardness and Durability: Z-Series ceramic media are made from advanced materials with high hardness, ensuring that they maintain their shape and effectiveness throughout multiple uses. This leads to greater consistency in surface treatment and a longer lifespan compared to traditional media.

Precision and Control: Z-Series ceramic media provide a finer and more uniform surface finish, allowing for better control over the peening process. This is crucial for components where precise surface characteristics, such as roughness and stress distribution, are critical.

Reduced Surface Contamination: Unlike steel shots, ceramic media do not produce metallic contamination during peening. This is particularly important in industries such as aerospace, where contamination can affect the performance and integrity of sensitive components.

Lightweight: Ceramic media is lighter than metal alternatives, which reduces the overall load during the peening process, improving efficiency and reducing wear on equipment.

3. Applications in Aerospace: Enhancing Component Strength and Longevity

The aerospace industry demands extremely high performance from its components, particularly those used in turbine engines, airframes, and landing gear systems. Z-Series ceramic shot peening media are highly effective in addressing the specific challenges faced in these applications.

Turbine Engine Blades and Vanes: Turbine blades are subjected to high temperatures, pressures, and rotational forces during operation. The peening process with Z-Series ceramic media introduces compressive residual stresses that help prevent crack initiation and propagation, extending the life of the blades. Additionally, this treatment improves the fatigue resistance of the components, which is vital for ensuring safe and reliable engine operation.

Landing Gear Systems: Aircraft landing gear systems are exposed to intense stress during takeoff and landing. The application of ceramic shot peening enhances the fatigue resistance and impact toughness of these critical components. By improving surface hardness and inducing compressive stresses, Z-Series ceramic media help reduce the risk of catastrophic failure and extend the lifespan of landing gear components.

Aircraft Structural Components: Aircraft structures, such as wing spars and fuselage components, are subjected to constant loads and vibrations during flight. Z-Series ceramic shot peening enhances the surface strength of these components, increasing their fatigue resistance and preventing the formation of cracks under repeated stress.

4. Applications in Automotive: Improving Durability and Performance

In the automotive industry, the performance, safety, and longevity of components are paramount. Z-Series ceramic shot peening media are increasingly used to enhance the surface characteristics of a wide range of automotive parts.

Crankshafts and Camshafts: Crankshafts and camshafts are key components in internal combustion engines, subject to high rotational forces, vibration, and thermal cycling. The application of Z-Series ceramic media during shot peening induces beneficial compressive stresses that help improve fatigue resistance, reduce wear, and enhance the overall durability of these critical parts.

Suspension Components: Automotive suspension components, such as control arms and shock absorber rods, experience significant stress from road conditions and the vehicle’s weight. Peening with Z-Series ceramic media improves their fatigue strength, ensuring better performance and a longer service life, especially under harsh driving conditions.

Transmission Parts: Transmission components, such as gears, shafts, and bearings, undergo repetitive loading during vehicle operation. Ceramic shot peening enhances the resistance of these parts to cracking and wear, thus improving the overall efficiency and longevity of the vehicle’s transmission system.

5. Stress Relief and Fatigue Resistance: The Core Benefits of Z-Series Ceramic Shot Peening

One of the primary reasons Z-Series ceramic shot peening is so valuable in the aerospace and automotive industries is its ability to relieve internal stresses and improve fatigue resistance in metal parts. Here’s how it works:

Residual Stress Induction: The high-velocity impact of Z-Series ceramic media on the component surface induces compressive residual stresses. These stresses are essential for preventing the initiation of cracks and delaying the propagation of existing microcracks, ultimately enhancing the material's ability to withstand cyclic loading and fatigue.

Stress Relieving: The shot peening process also helps relieve internal tensile stresses that can cause material failure. By ensuring a balanced stress profile, components become more resistant to cracking, wear, and corrosion over time.

Improved Performance Under Fatigue: The introduction of compressive stresses on the surface significantly enhances the component's performance under repeated loading cycles. This is especially important in high-stress environments such as aerospace and automotive applications, where failure due to fatigue can have catastrophic consequences.

Conclusion: A Future of Enhanced Performance with Z-Series Ceramic Shot Peening Media

The introduction of Z-Series ceramic shot peening media represents a significant advancement in surface treatment technology for both the aerospace and automotive industries. By providing superior durability, precision, and stress relief, these advanced ceramic media are helping to improve the performance and lifespan of critical components. As both industries continue to evolve and face new challenges, the adoption of Z-Series ceramic shot peening media will undoubtedly play a crucial role in driving innovation and ensuring the safety and reliability of the next generation of aircraft and automotive vehicles.

Tags:

#CeramicShotPeening #Aerospace #Automotive #SurfaceStrengthening #FatigueResistance #StressRelief #ZSeriesMedia #PrecisionManufacturing #ComponentDurability #IndustrialApplications